Research focusing on the flow and transport phenomena in complex two-phase systems.

About

We study fundamentals of complex multiphase flows and their application to sustainable processing. We investigate, in particular, two-phase systems involving liquids, including drop interfacial phenomena, characteristics of two-phase flows from micro to pilot scales, rheology and the effects of viscoelasticity.

Our aim is to gain fundamental insights of the underpinning small scale flow and interfacial phenomena and their interactions with mass transfer, that we use to understand the global behaviour of the multiphase processes and to develop predictive models. We are currently exploring the role of machine learning and data driven approaches on multiphase flow predictions.

Applications include intensified continuous liquid-liquid flow extractions for the separations of metals such as platinum group metals and actinides/lanthanides and of biomolecules; processing of complex formulations; microfluidics for analysis and droplet generation. We have a sustained track record of collaborations with industry that have enabled technology translation and provision of consultancy.

Our work is supported by state-of-the-art experimental facilities and advanced instrumentation and measuring techniques.

Study areas

The studies address areas such two-phase liquid flows in pipelines relevant to flow assurance in oil production and transportation, intensified liquid-liquid extractions and reactions for spent nuclear fuel reprocessing, metal separations and biofuel production, and processing of suspensions in complex fluids for healthcare applications.

- Large scale liquid-liquid flows

The flow of oil and water inside a pipe is an important phenomenon which is often found in chemical and oil & gas industries, for example during transportation of crude oil and water mixture over long distances from offshore to onshore platforms. It is known when the two fluids flow together, they can flow in different flow patterns and each pattern can give arise to different pressure drop and energy consumption. With limited availability of the resources, it has now become essential to be able to predict accurately the flow patterns for increased production efficiency and for safety purposes as well as for future design of the system.

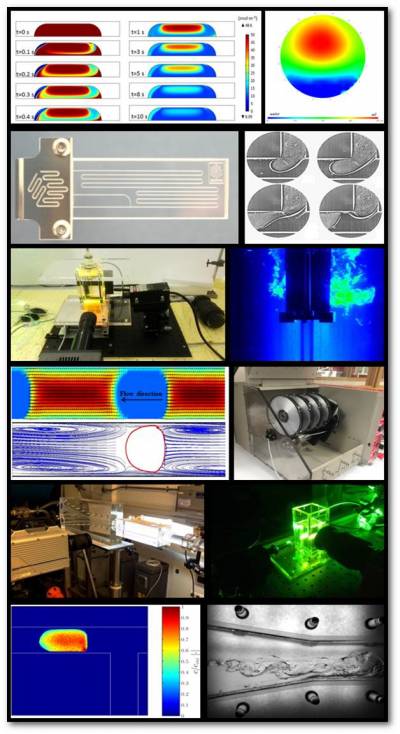

Our team aims to characterize and understand different oil-water flow phenomena, focusing on different regions of the flow pattern map through both experimental and numerical investigations. Different inlet geometries, channel sizes and fluid properties are currently being studied. High speed camera is extensively used for flow pattern identification and to extract data such as drop sizes and wave characteristics. PIV and High Speed PIV are used to gain better understanding of the flows and a wide range of conductance probes are used to capture interfacial phenomena. Simulation results are compared against experimental data and used to design future experiments.

YouTube Widget Placeholderhttps://youtu.be/UJWlhC1TW4s - Microfluidics

Microfluidic devices in the range of a few hundred μm have received increased attention over the last decade driven by process intensification demands, notably in two-phase operations. With advantages such as thinner fluid layers and large surface-to-volume ratio, heat and mass transfer rates are significantly better and when coupled with narrow residence time distributions, a higher efficiency process can be achieved.

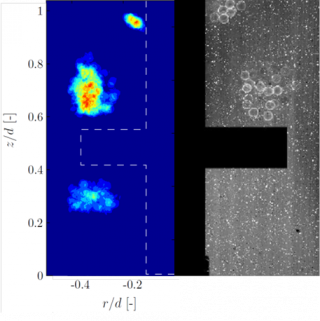

Our group aims to gain fundamental understanding of micro-flow phenomena in two-phase systems. Studies involving interfacial mass transfer and recirculation patterns can be achieved with the state-of-the-art equipment within our research laboratory, such as, Laser Induced Fluorescence (LIF) and micro Particle Image Velocimetry (µPIV). Currently, there are multiple ongoing research involving droplets formations and the displacement process within the microfluidic system.

YouTube Widget Placeholderhttps://youtu.be/irluQIXLV_c YouTube Widget Placeholderhttps://www.youtube.com/watch?v=TOspRHePC6c - Intensified Processes

In ThAMeS, we develop innovative intensified technologies that have a direct impact on the energy industry and particularly the nuclear, biofuel, and hydrometallurgy sectors.

Main applications

The main use of these technologies is in the recycling and reprocessing of metallic components from the (nuclear) waste, and thus reducing the amount of metals needed to be mined and reducing the volume (and toxicity) of the rest of the waste. In the production of biofuels new approaches based on waste oils and fats are substituting earlier ones that are controversially competing with crops for food.

Intensified reactors

Processes are performed in intensified, small-scale units (micro to milli scale), which reduce the amount of solvent volume required, and make possible the use of expensive solvents such as ionic liquids. The reduction in volume is compensated by the high efficiencies achieved. Rapid and efficient mixing is an important trait in these processes and is significantly enhanced in small channels by the short diffusion lengths, recirculation, and convection induced by surface tension gradients. The industrial application of intensified units requires a good understanding of the whole system and in ThAMeS we perform full hydrodynamic & mass transfer characterisation of the key features on multiphase flows.

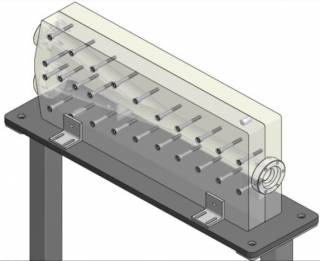

Scale-up strategies

In ThAMeS there is ongoing research to increase throughput using small-scale devices. Scale-out (or number-up), which is the use of parallel channels to increase the throughput in the two-phase contacting equipment, is mainly used instead of conventional scale-up (increase in size). The objective is to design multichannel reactors and increase the total processing capacity of the process. This is achieved by using novel methodologies based on resistance network models for multiphase mixtures.

YouTube Widget Placeholderhttps://youtu.be/RY1wcrZvIjo - Coalescence Phenomena

In long-distance oil transportation, the coalescence of water or oil droplets affects the pressure drop and energy consuming. Previous studies reveal that drop coalescence is influenced by the fluid properties (density, viscosity and interfacial tension) and the operation conditions such as the relative velocity between two coalescence bodies. This research aims to find how the fluid properties and operation conditions affect the coalescence process and build models to predict the coalescence rate.

YouTube Widget Placeholderhttps://www.youtube.com/watch?v=PmmbH3UKdBE YouTube Widget Placeholderhttps://youtu.be/QKyHmb9-1kg YouTube Widget Placeholderhttps://youtu.be/of85NUCruEM - Processing of Complex Fluids

Non-Newtonian fluids, such as paint, toothpaste, blood are ubiquitous in nature, and they are widely used in chemical engineering, bio-chemical engineering, food processing, oil exploration, and medical engineering.

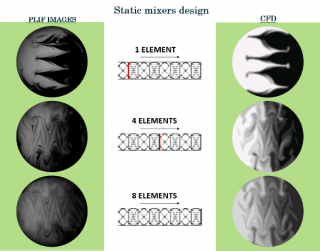

In our group we use both experimental optical techniques and computational fluid dynamics to obtain critical information of different physical systems and tackle new manufacturing challenges. Specifically, our main interest focuses on the mixing of complex non-Newtonian liquid-liquid and solid-liquid mixtures in both batch and continuous processes with an insight into the rheological properties of the materials used.

YouTube Widget Placeholderhttps://youtu.be/Vgvg5kMshms

Facilities and Resources

The two-phase flow studies are carried out in state-of-the-art experimental facilities ranging from pilot scale flow rigs to microfluidics set ups. The facilities are equipped with a range of instruments for high speed imaging and for the detailed measurement of velocity fields, phase concentration profiles, drop size distribution, and phase continuity.

- Particle Image Velocimetry (PIV)

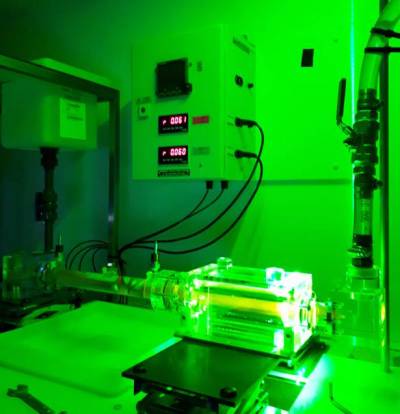

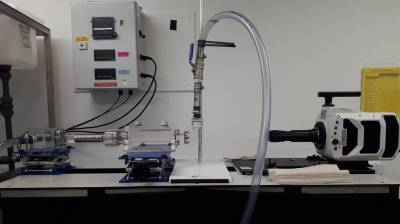

Different cameras and lasers are available for Particle Image Velocimetry (PIV) and Lase Induced Fluorescence (LIF) studies.

- For pulse laser experiments: Nd:Yag green laser (532 nm) (Litron Laser, 14.5 Hz, 1200 mJ) and a straddling CCD camera

- For the continuous laser: A DPSS green (532 nm) continuous laser system and Phantom v1212 by Vision Research

With these systems we have carried out

- Standard PIV measurements

- Micro-PIV measurements

- High speed PIV measurements

- Laser induced fluorescence studies

Two colour micro-PIV setup

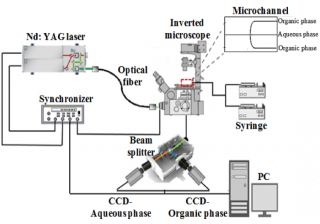

We have developed a two-colour micro-particle image velocimetry (μ-PIV) technique to obtain velocity fields simultaneously in two immiscible liquid phases.

- Double pulsed Nd:YAG laser unit (Laser Class 4)(Nano PIV Litron Lasers®)

- Microscope unit (Nikon Ti-400)

- Synchronization unit (TSI synchronizer)

- Beam splitter unit (Andor® Technology)

- 4MP, 34fps CCD camera Link® Base

- 12-bit CCD sensitive camera Dicam pro®

- Pilot Scale Flow Facilities (PSFF)

Flow Loop #1

- Oil and water test fluids

- Test pipe: acrylic, 26 mm ID

- Length: Front loop 4m, back loop 4m

- Velocities: 0 – 1.2 m/s for each phase

Flow Loop #2

- Oil and water test fluids

- Test pipe: acrylic or stainless steel, 37 mm ID

- Length: Front loop 7m, back loop 7.5m

- Velocities: 0 – 4 m/s for each phase

Inlet-Designs

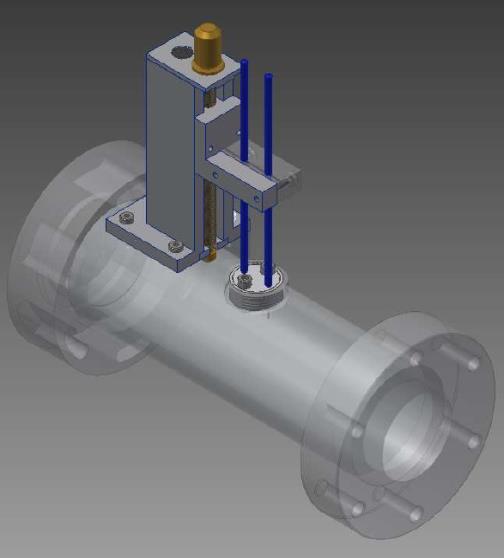

Continuous mixing rig

- Material: Acrylic (transparent) and steel

- Pipe ID: 25.5 mm

- Length: Variable. Possibility to attach different mixing sections

Flow rates: 0-3 L/min

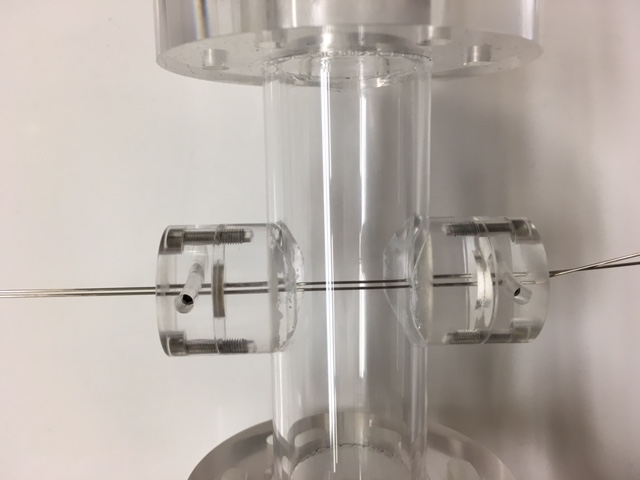

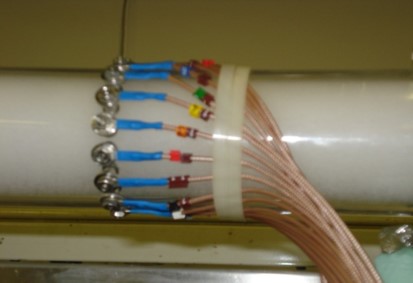

- Electrical Probes in Flow Loops (EPFL)

Ring probe

Continuity of phase in contact with the pipe wall

Double-wire conductance probe

Interface height/wave characteristics in stratified flows.

Dual-conductance probes

Phase distribution; Drop size distribution

Electrical Resistance Tomography System

Phase distribution in a pipe cross-section

- Countercurrent Chromatography (CCC

- Countercurrent chromatography (CCC) is an intensified liquid-liquid separation technique that takes place along a continuous length of tubing, which is wound around a drum (called a bobbin). One of the liquid phases (the stationary phase) is held in place by a combination of hydrodynamic and hydrostatic forces generated as a result of rotating the tubing in a planetary motion, while the second (mobile) phase is then continuously pumped through it in such a way that there is good retention of the stationary phase. Planetary rotation of the column also results in a variable centrifugal field. This creates a series of simultaneous mixing and settling zones along the tubing, promoting solute transfer between the phases, and therefore, separation of species with different partition coefficients. Due to the high-speed rotation of the column a large number of stages can be generated in a single machine. For example, a sample injected into the mobile phase will experience 800 repetitive mixing and settling steps in a minute when the motor rotor speed is 800 rpm, thus promoting highly efficient separations.

In our laboratory, work has mainly focused on understanding the fundamental hydrodynamic behaviour of different solvent systems in the CCC instrument, to enable its wider application in metal extraction separations.

- Analytical Equipment

Rheometer MCR302

Kruss Tensiometer K100

Pendant drop Tensiometer

Close

Close