B-made, The Bartlett Manufacturing and Design Exchange supports the Bartlett School of Architecture's students and staff with manufacturing facilities and expertise.

On this page:

B-made Induction

The B-made Induction is completed in two steps, first online then in-person. Access to B-made is only granted to current Bartlett students and staff who have completed B-made's two-step Induction process. Returning inducted users can 're-fresh' their workshop cards in the B-made Hub.

Step 1: Moodle

Step 1 of the B-made Induction, the online Moodle course, consists of a series of interactive videos and quizzes covering the essential technical skills training required to safely and effectively use B-made's workshop facilities. Bartlett School of Architecture students are automatically enrolled at the beginning of the academic year. Please contact us if you are a member of staff who would like to be enrolled.

Step 2: in-person training

Sign up for Step 2, the in-person training on the Moodle page. Sign up is first-come, first-served. The induction schedule disrupts access for workshop users, so please ensure you sign up as soon as possible as there are limited sessions in each term. Additional opportunities to get inducted are offered at the start of each term, so please ask your tutor about anticipated use of B-made facilities within your module or programme. Inducted workshop users will be issued a B-made workshop card. Use this personalised workshop card to access B-made's facilties. B-made's physical workshop facilities are open 09:30 to 17:00 weekdays and we close daily for lunch from 13:00 to 14:00. Access to further resources and advanced manufacturing processes is obtained through further advanced inductions.

Please contact Viktoria Viktorija v.viktorija@ucl.ac.uk if you have questions or concerns.

Schedule for first term

B-made facilities are open to students during term times throughout the academic year. B-made will open to users in Term 1 from Monday 25 September 2023 through to Friday 15 December 2023 but will be balancing inductions with open access. Please see our site-specific schedules below. We will update this page throughout the term as planning allows. B-made facilities will be closed to users from December 18, 2023 to January 8, 2024.

- B-made at 22 Gordon Street

Winter schedule

- early closure Dec. 13 (workshops close at both sites 14:00)

- last day to access B-made Dec. 15

- B-made workshops closed Dec. 18 to Jan. 5

Term 2 Inductions

Here East: Monday 8 January (workshop closed to other users)

22 Gordon Street: Monday 9 January (workshop closed to other users)

- B-made at Here East

Winter schedule

- early closure Dec. 13 (workshops close at both sites 14:00)

- last day to access B-made Dec. 15

- B-made workshops closed Dec. 18 to Jan. 5

Term 2 Inductions

Here East: Monday 8 January (workshop closed to other users)

22 Gordon Street: Monday 9 January (workshop closed to other users)

- B-made at 77 Wicklow Street

- The workshop will be closed to users from December 18, 2023 to January 8, 2024.

Returning workshop users and lost cards

Welcome back

Students who completed the B-made Induction in the 2022/23 academic year, can come to either of the B-made Hubs and exchange their workshop card for a new 2023/24 card and the Technical Services team will update your records.

Lost workshop cards

Returning inducted workshop users who have lost their workshop card can contact us through the B-made Hub email: b-madehub@ucl.ac.uk prior to coming to collect a replacement card so that we can search our records. Please allow at least 24 hours for us to recieve and respond to your message. We will endevour to respond as soon as possible, but please note that the team are busy at the begining of Term 1 so please wait until we have responded to your email before coming to the Hub to obtain your replacement card.

Please include in your message the following details:

- Full name

- UCL ID

- Bartlett programme / course

B-made workshop facilties

B-made, is a popular and widely used resource for Bartlett students and staff interested in historical and cutting-edge analogue and digital fabrication. We provide a practical, contextual and manufacturing-based education facility enabling users direct access to specialist equipment and processes. Students pedagogically and physically develop their skills alongside their design projects through the lens of manufacturing with us. In theory and practice, B-made is not a service provider; Once trained on the revelant process, workshop users make their own projects except for machinery run only by staff for safety purposes. B-made staff are always on site to support from planning stages to finishing details. It is therefore critical that students and staff planning to use B-made, allow time to undertake the practical training needed to complete their physical project when planning the scope of their design outputs. Please note that all workshop users must complete the 2-step process of the B-made Induction consisting of online training and in-person validation of readiness to use the workshop facilities.

The team

The B-made team is made up of technical staff and lecturers with a wide breadth of techincal, art and design backgrounds and expertise. Our team work to support the technical knowledge required to facilitate the scope of our operations and support students throughout their projects and education. The B-made team is a critical component to pedagogy of The Bartlett Manufacturing and Design Exchange, in it is ethos of training and empowering designers and researchers to question and challenge the thresholds of manufacturing and design, and how a reciprocal approach can advance design thinking and the future of manufacturing.

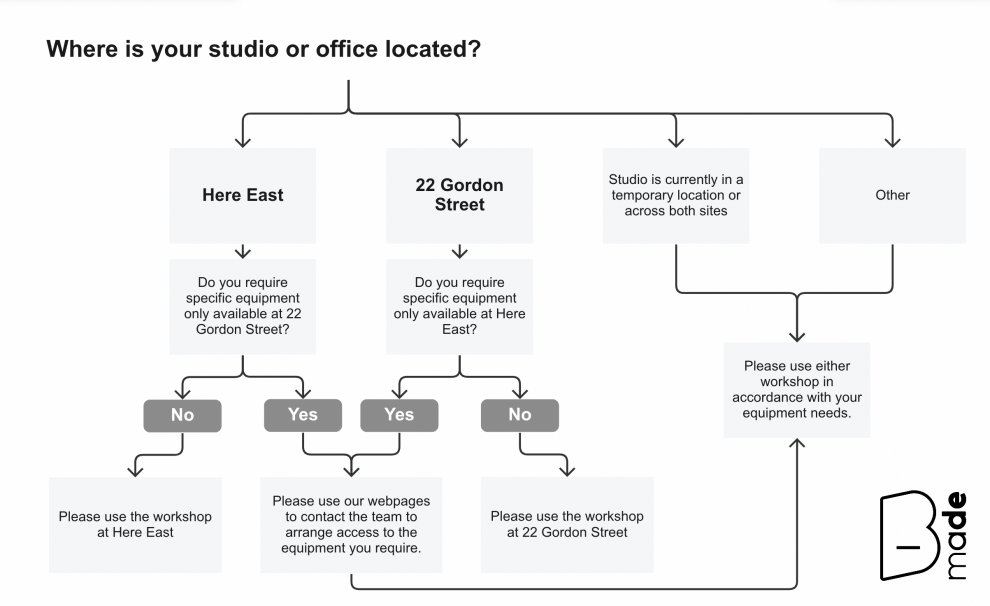

Locations

B-made operates across multiple sites. Our two main workshop are located within The Bartlett School of Architecture's Bloomsbury site at 22 Gordon Gordon Street in central London, and The Bartlett's UCL at Here East location in the Queen Elizabeth Olympic Park. The workshop at 77 Wicklow is exclusively for Landscape students as it and the building have limited occupancy. Due to increasing demand on our resources, we are unlikely to be able to extend access to students not based at that workshop location. There are equipment specific exceptions to this guideline such as within our Robotics program and on specific kit such as our water jet cutter; In circumstances where specific equipment is not available at your workshop location, you can contact the B-made team and arrange to use that specific equipment. Find more information on specialist activies across B-made's webpages. Key equipment and processes are listed by site below as a general summary. Please note that there are variations in the equipment and machinery available at each site, but there is general parity of capability across 22 Gordon Street and Here East workshops.

Please note that Students should use the B-made facilities available at the site where their studio is based.

- 22 Gordon Street

Wood-working:

- pillar drills

- bandsaws

- lathe

- tablesaw

- planer / thicknesser

- carving tools / chisels / etc.

- various standard and specialist hand tools and power tools

Metal-working

- MIG and TIG welding

- brazing

- metal cut-off saw

- metal bandsaw

- lathes

- bridgeport milling machine

- guillotine

- metal sheet roller

- tube bending

Other analogue equipment

- vacuum-former

- kiln

Numerical manufacturing

- Here East

Wood-working:

- pillar drills

- bandsaws

- tablesaw

- planer / thicknesser

- wall saw

- carving tools / chisels / etc.

- various standard and specialist hand tools and power tools

Metal-working

- MIG and TIG welding

- metal cut-off saw

- metal bandsaw

- lathe

- bridgeport milling machine

- guillotine

- metal sheet roller

- brake press

Numerical manufacturing

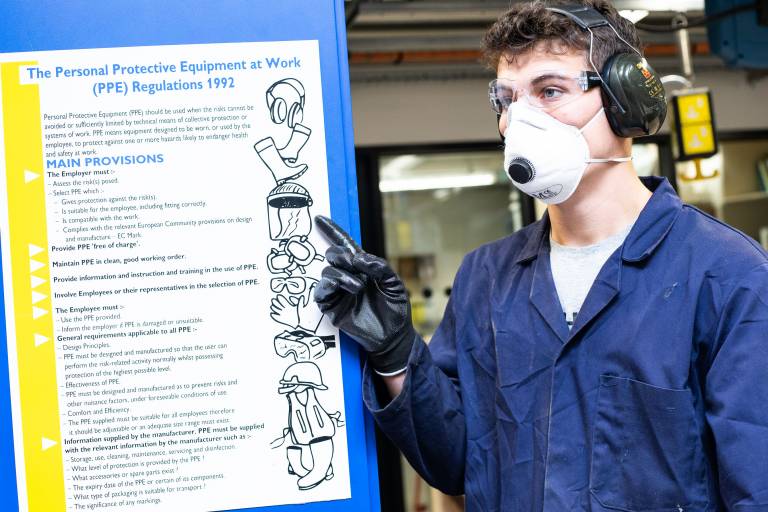

Health and Safety

B-made strives to deliver cutting-edge resources for manufacturing safely. The B-made Induction serves as a baseline entry requirement. It ensures all workshop users are trained on essential tools, evacuations plans, first aid procedures and workshop conduct so that all users can operate safely. It is everyone's responsibility to ensure we are all working in a safe environment. Bartlett collegues and students must understand that it is the responsibility of individuals who introduce new risks to own those risks and take the appropriate measures to reduce the likelyhood for harm to occur. Please take a few moments to read through the information below as you may not be aware that you have responsibilities and obligations to oblige to various Government / legal / UCL or Bartlett Policies.

- The Control of Substances Hazardous to Health (COSHH)

COSHH regulations provide a framework to protect people against health risks from hazardous substances. Students or tutors introducing the use of substances into projects should visit the government’s Health and Safety Executive website regarding COSHH to ensure they are following regulations.

B-made manages its own COSHH within the workshop and is not responsible for substances outside the workshops or those brought into the workshop by staff or students. B-made can advise, inform or support staff and students regarding COSSH, but individuals who introduce a risk, own that risk. Tutors and students must ensure they understand any risks involved before defining projects by particular chemicals. Always remember to review the material safety data sheet of chemicals you are using. A safety data sheet is not a risk assessment. You should use the information it contains to help make your a risk assessment for your particular use of the substance.

- Resin

B-made respects and supports The Bartlett’s resin ban policy and does not permit its use in the workshops. It is an unsustainable material with various hazardous by-products, during and after casting (sanding/finishing, etc.). Health and environmental concerns and the school’s duty of care supersedes the design opportunities this material presents. The Bartlett prohibits the casting of resin by Bartlett students, indoors or outdoors, on or off the premises. No work cast in resin will be accepted as part of a portfolio submission and student work that contains resin is removed from shows. This includes expanding foams, which are hazardous to health and highly flammable.

- Model Board and MDF

B-made no longer supports the use of dust-producing model boards or MDF on our CNCs. The associated health risks and HSE policies have impacted the decision to protect air quality for students and staff. We now offer model board that chips as it is milled, creating a safer by-product during milling. MDF is also not permitted on the laser cutters.

- Spray Paint

B-made only supports the use of water-based spray paints in the 22 Gordon Street workshop – there are no spray-painting facilities at Here East. To ensure water-based spray paints are used, the B-made Hub now stocks and sells water-based spray paints.

UCL staff and students can learn more about indivduals' responsibilities and risk mitigation by visiting B-made's Health and Safety page for more information.

Close

Close