B-made's water jet is located within B-made's workshop in UCL at Here East and is available to inducted workshop users who must complete an Advanced Induction specific to the B-made water jet.

On this page

B-made water jet cutting

Water jets are industrial machines that use a high pressure stream of water mixed with abrasive garnet to cut through sheet materials. This subractive Computer Aided Manufacturing process is similar to a laser cutter in that is uses 2D CAD files to run the machine's tool path, but water jets are able to cut through metals and other materials that B-made's laser cutters cannot cut through. Water jets are benefitial tools for cutting materials that would be otherwise affected by the heat-intensive process of metal laser cutting or plasma cutting.

B-made's water jet is a small scale machine not suitable for large scale production. As such, workshop users are welcome to use it as a prototyping tool, to test out processes but should not design their project to rely on the use of B-made's only water jet to fabricate large quantities of outputs on this machine. Learn more about the specifics of our water jet throughout this page, and use B-made's Process Tutorials with members of our team to discuss complimentary approachs or alternative methods of fabrication.

Accessing the water jet

Anyone who would like to use the B-made water jet within B-made's Here East workshop, first needs to complete the B-made Induction. Inducted workshop users should familiarise themselves with the information shared on this page. Once you have a suitable 2D CAD file that fits the water jet dimensions contact bmadewaterjet@live.ucl.ac.uk and include the file, material preference/s and any important information including your project timeline. A technician will reply to your query and provide proliminary feedback on your expected use of the water jet and will schedule a Process Tutorial to discuss your project in detail and arrange your Advanced Induction. Once you have completed the training provided through the Advanced Induction for the water jet, you will need to confirm that your file is ready to be cut. You will then be booked in to use the water jet. You will personally be responsible for staying with the water jet and supervising it as it cuts your file. It is critical that you not leave the machine while it is cutting. You must immediately alert someone in the B-made team of leaks, nozzle blockages or other issues. You will also be responsible for collecting your cut materials and cleaning up your job.

Specifications

B-made has only one Protomax Abrasive water jet cutter and it is located within our B-made workshop in UCL at Here East. The machine's cutting extent is 300mm x 300mm. Maximum depth is 25mm thickness but sheet material thickness is subject to B-made's stock availability. Remember to account for a tolerance of +/- 0.15mm

Cutting limits

- Machining extents: 300mm x 300mm

- Z limit: 25mm

- Tolerance +/- 0.15mm

Important instructions

Please remember the following specifications.

- File naming structure should be as follows: Surname_firstname_thickness_material_xquantity.dxf (for example: Toma_Claudia_3mm_steel_x2.dxf)

- Please leave at least 3mm between pieces to be cut

- Channels or holes less than 1.5mm in width cannot be cut due to the kerf of the machine

- The machine cannot understand intersecting lines or lines connecting/coming off a closed shape to be cut out

- Please check your geometry is clean and closed before sending

- Include a line drawn and labelled at 100mm, so staff may check the file has opened at the correct scale

Cost

- £10 for the first 30 mins of cutting time per session (excluding materials).

£5 for every additional 30 mins of cutting time per session (excluding materials).

There is a nominal fee to run the machine to help cover its time and energy intensive process and the use of the expensive consumable garnet. Workshop users considering using the water jet are therefore encouraged to consider whether there are alternative methods of production such laser cutting, CNC routing or plasma cutting that might be suitable for their project especially if they are not concerned with heat changing their material though such. In many cases, alternative methods of making may better suit your project and provide a wider option of materials and sizes. Students should budget time to learn how to safely use the water jet cutter and also account for the time involved in supervising the cutting of their project.

Material options

The following 310mm x 310mm sheet materials are stocked by B-made and are available to use on the water jet. Note that the water jet can only cut an area of 300mm x 300mm. Materials and thicknesses not below will require special permission for use on the water jet.

Prices

310mm x 310mm sheet material

| Sheet thickness | Mild Steel price* | Aluminium price* |

|---|---|---|

| 0.8 mm | £2.95 | N/A |

| 1.0 mm | £3.60 | £2.25 |

| 2.0 mm | £7.40 | £4.50 |

| 3.0 mm | £10.80 | £6.75 |

| 5.0 mm | £13.61 | £11.70 |

| 6.0 mm | £15.00 | £14.00 |

*Note that prices are subject to change in accordance with supply costs which are dictated by international metal prices. Listed prices are accurate as of September 2022. Material prices do not include the 1/2 hourly rate to use the water jet.

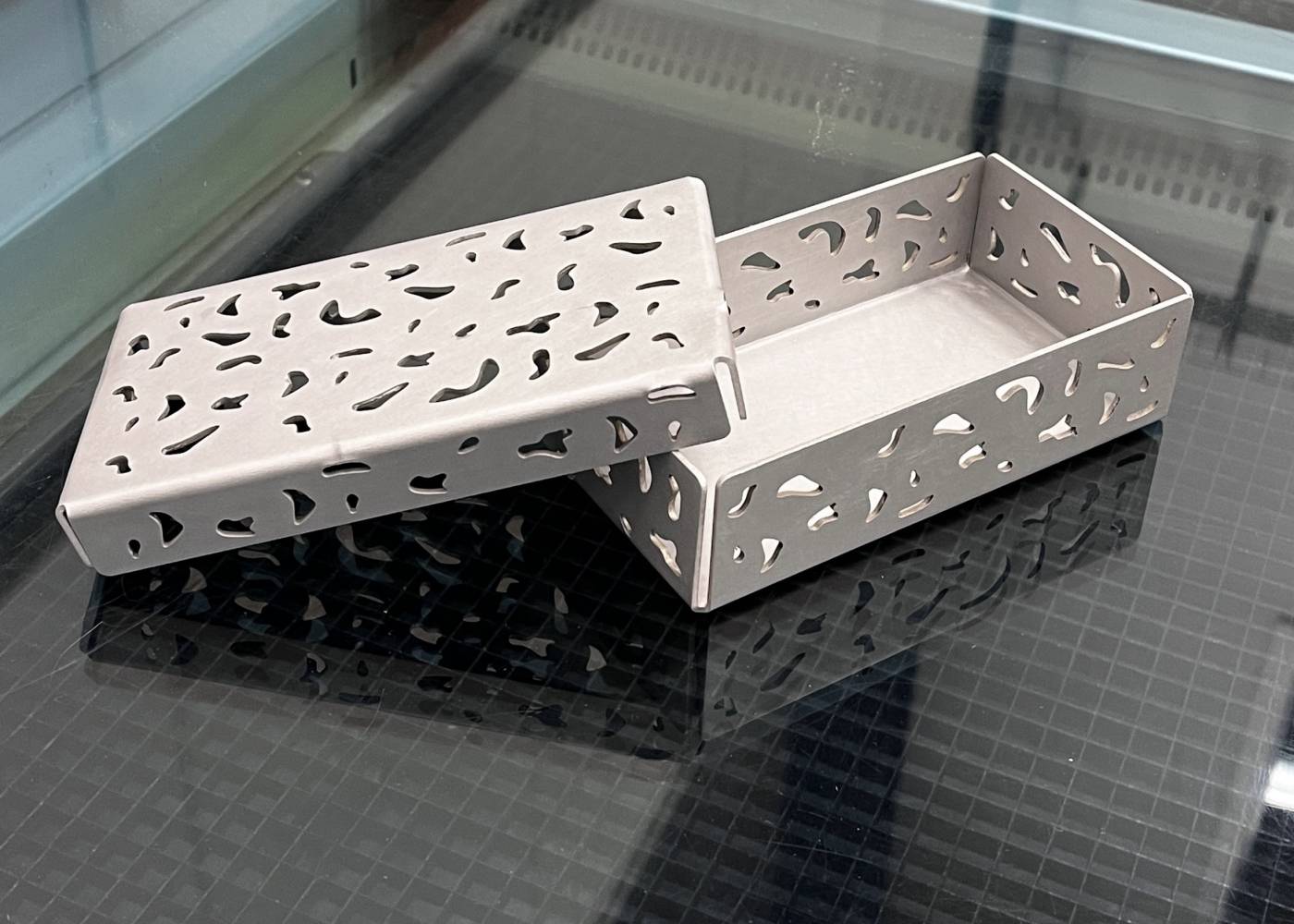

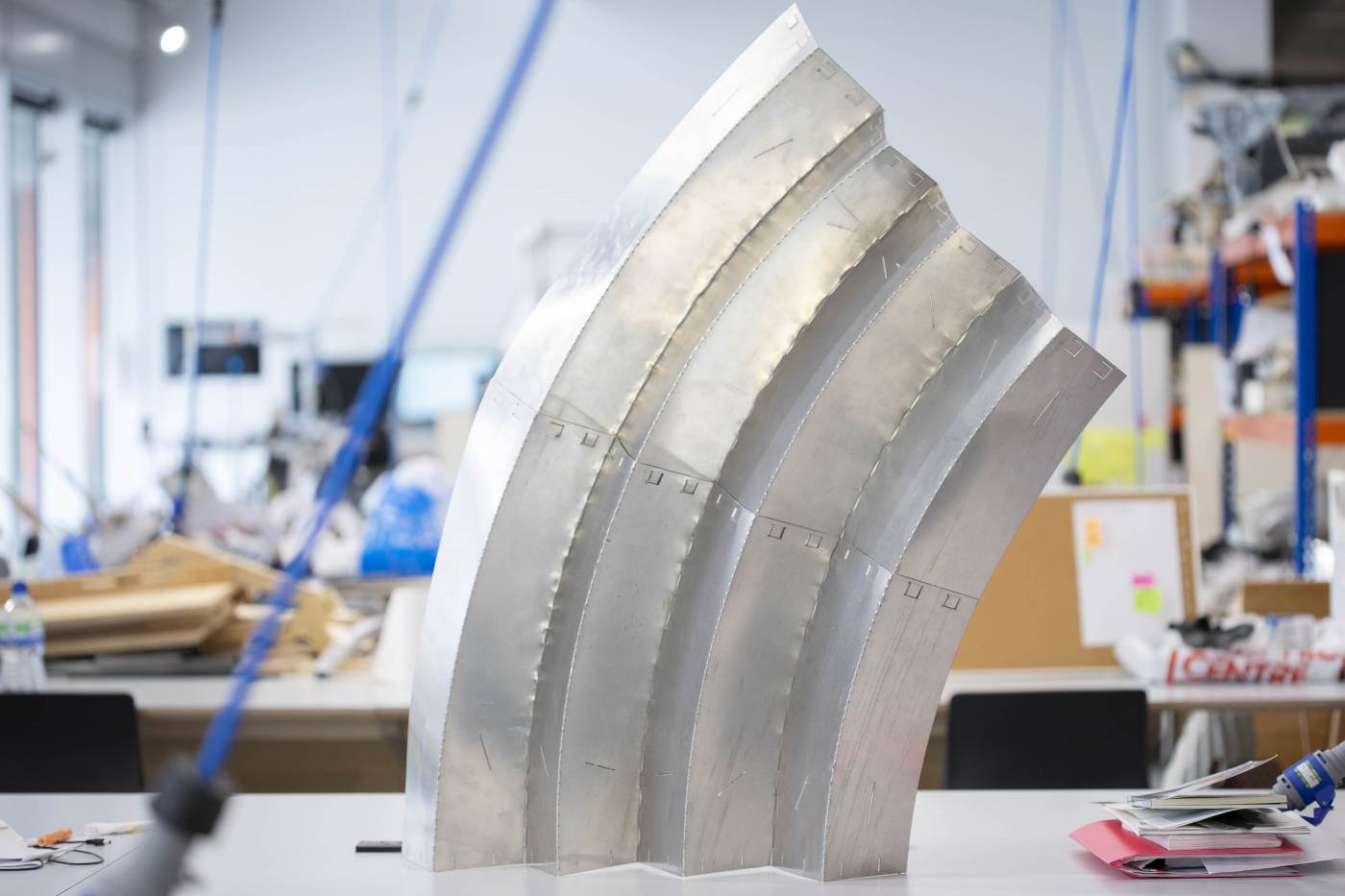

Examples of past work

Close

Close