B-made enables Bartlett student access to desktop 3D printers across both sites. B-made also runs a 3D printing service open to the wider UCL community and industry professionals.

On this page:

B-made's 3D printing options

B-made's 3D offers pay-for-print services for our industrial grade machines, B-made also enable Bartlett students to access and operate desktop 3D printers located throughout our buildings. Find out more below.

- Desktop 3D printers (bookable by Bartlett students only)

Who can rent a desktop 3D printer?

Bartlett Students only. If you are from a different faculty please check out information on the pay for-print service.

How can students access a machine?

Students who have completed the B-made Baseline induction (hosted on Moodle) will have access to a booking system. Students can select a timeslot to use one of the printers.

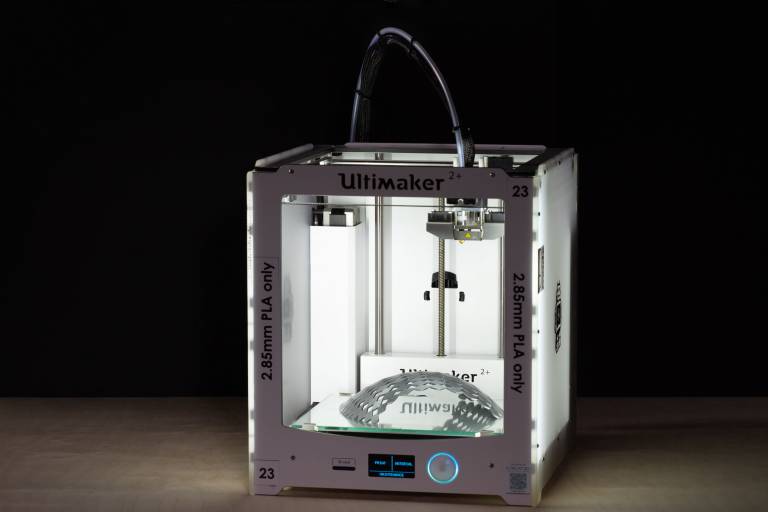

Ultimaker 2+

- material: 2.85mm PLA filament

- build size X Y Z: 223mm x 223 x 205

- file transfer: SD card

- software: Ultimaker Cura

- 3D printing technologies (service run)

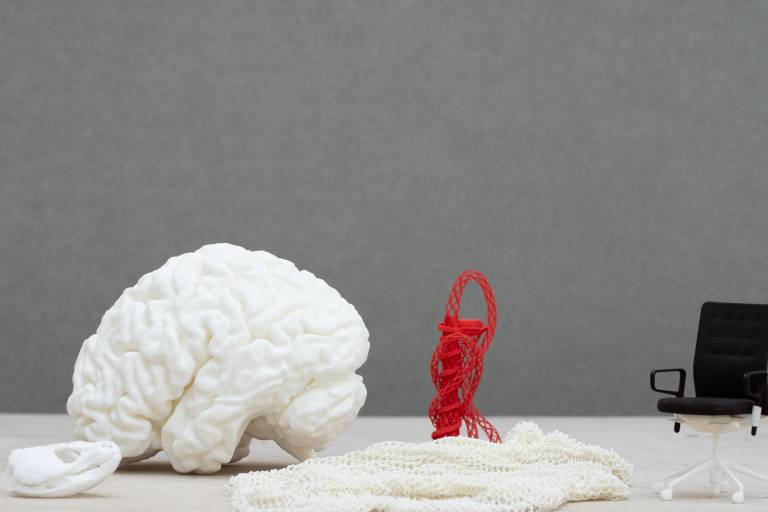

3D printing technologies

B-made offers advanced capabilty in 3D printing through its 3D printing services. Unlike other numerical manufacturing equipment in B-made, the machines listed below must be run by B-made technicians so are not available for students to use on their own.

Files from students, UCL researches and staff and other external industry professionals can be submitted to the 3D Printing department by Email:

The 3D printing team will review the data, advise and quote each request based on the technology used, size and geometry.

B-made has temporarily postponed any in-person (face to face) file submissions until further notice. Please contact us via the email above only.

Please note that the 3D printing team will respond to emails as soon as possible and are not available in the afternoons to ensure they can process the pay-for-print services.

Send files to the B-made 3D printing team:

3dp.bartlett@ucl.ac.uk

Learn more about our capability below:

- SLS (Selective Laser Sintering)

- Polyjet Object Connex (Multiple Polymer Printing)

- SLA (Stereo Lithography)

- FDM (Fused Deposition Modelling)

SLS

SLS properties

- machine: EOS Formiga P100

- build size: 240mm x 190mm x 320mm

- material: PA 2200 (nylon powder)

- cost: calculated on bounding box

SLS advantages

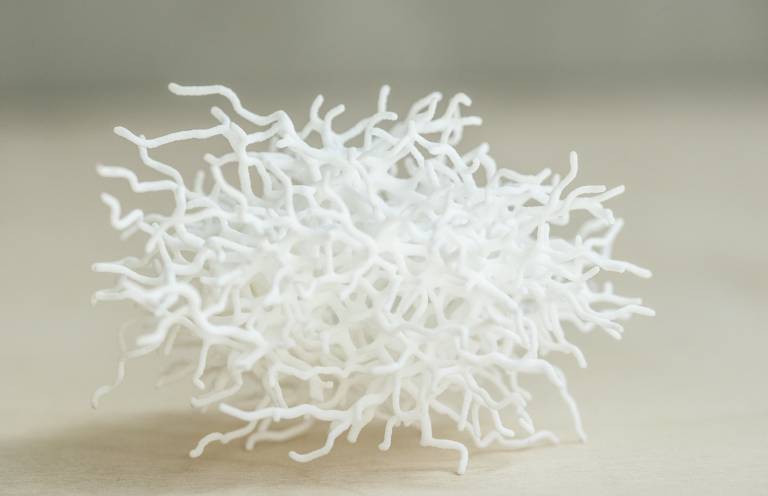

- fine detail

- strong

- low cost when small

- flexible if thin

- good surface finish

- can print any geometry (no support material required)

SLS disadvantages

- 1 week lead time*

- white material only (can later be died or sprayed)

- large objects can warp

Polyjet (Objet)

Polyjet properties

- machine: Stratasys J835

- build size: 350mm x 350mm x 200mm

- material: acrylic-based resin (rigidity 30 shore to 95 shore)

- cost: calculated by weight of material used

Polyjet advantages

- dual-material printing

- full colour prints: Pantone validated

- transparent or opaque

- glossy or matte surface finish*

- can mix materials: desireable flexibility

- rubber-like materials

- 24-hour lead time*

- soluable support material

Polyjet disadvantages

- can be expensive depending on geometry and size

- support material can be difficult to remove

- surfaces that require support material have a matte finish (underside)

SLA

SLA properties

- machine: Form labs – Form 3

- build size: 140mm x 140mmx 170mm

- material: 'clear' acrylic-based resin (rigid)

- cost: calculated by amount of material used

SLA advantages

- lower cost compared to Polyjet

- support structure enables hollow parts

- can be polished or sprayed for high transparency

SLA disadvantages

- can be brittle

- small build volume

- translucent only (can be sprayed)

- supports leave behind small spikes

FDM Z18

FDM properties

- machine 1: Ultimaker 2+ (190mm x 190mm)

- machine 2: Prusa I3 mk2.5s (250mm x 200mm x 200mm)

- material: PLA (rigid) other materials upon request

- cost: calculated by machine running-time

FDM advantages

- large build volume

- low cost for size of model produced

FDM disadvantages

- slow

- poor surface finish

- support material can be difficult to remove

- a flat base will warp

CAD/CAM advice for 3D printing

3D printers require good quality data in order to create a successful model. Data integrity is vital before setting up a 3D print. Here are some things to check for before sending a model to print:

- units are set to mm

- model is the correct scale/size

- model is moved to origin location

- all objects are closed solids

- minimum thickness 1mm +

- export as STL file

Avoid or repair

- single surfaces

- missing surfaces

- duplicated geometry (overlapping)

- open edges

- files over 200mb

- self-intersecting geometry

- floating elements (not attached)

- geometry located away from the origin

- non-manifold edges

Material Advice

The material selected for each 3D print will vary depending on what is required of the model and its geometry. When we review your data and design we will be able to advise you on the most appropriate technology and material to use. Alternatively, if you know what material finish you require, we can give design guidelines to optimise the geometry to suit the process. A few material criteria are often:

- colour/transparency

- surface finish

- level of detail

- cost

- strength/functional properties

- lead time

- post processing option

- support structure/material

Close

Close