The mechanical workshop undertakes the construction of all mechanical systems, whether they be flight or developmental. These vary from plasma detectors to full telescopes and from radiation shields to cryogenic coolers.

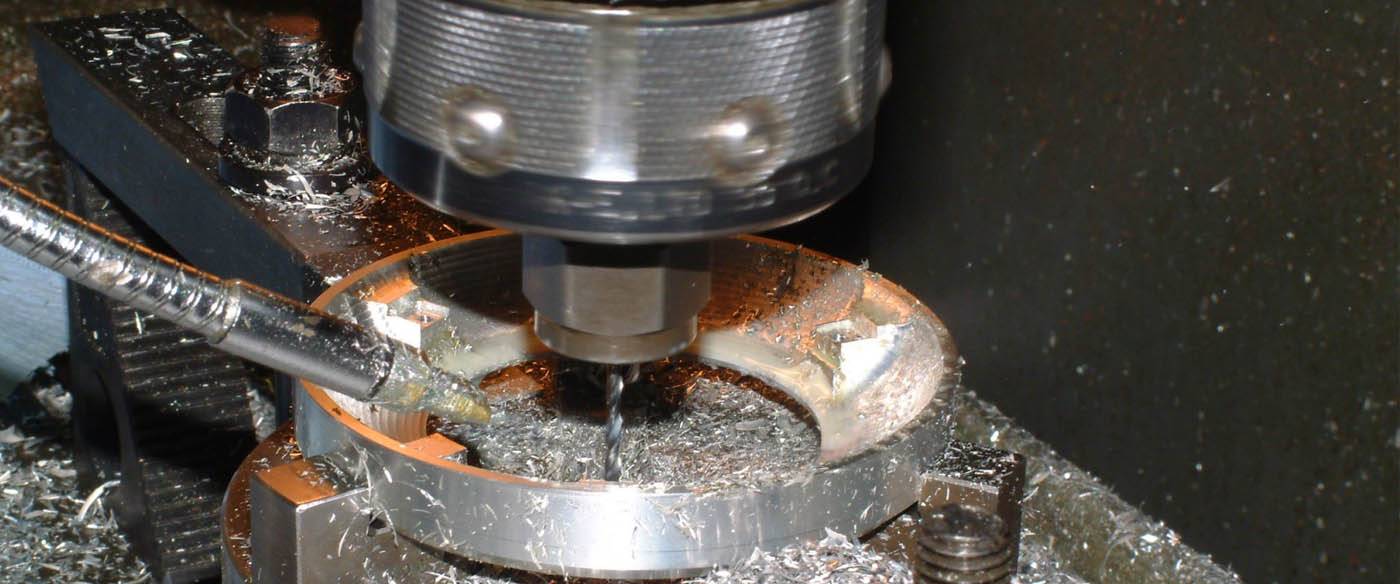

4 axis CNC milling can be performed on a variety of specialised materials approved for space flight use.

XYZ mini mill allows 4 axis CNC milling of space flight components.

Metal turning of stainless steel in the CNC lathe.

Metal turning of aerospace grade aluminium.

Nirspec CAA Instrument being assembled onto the support frames. The main hemisphere is gold plated.

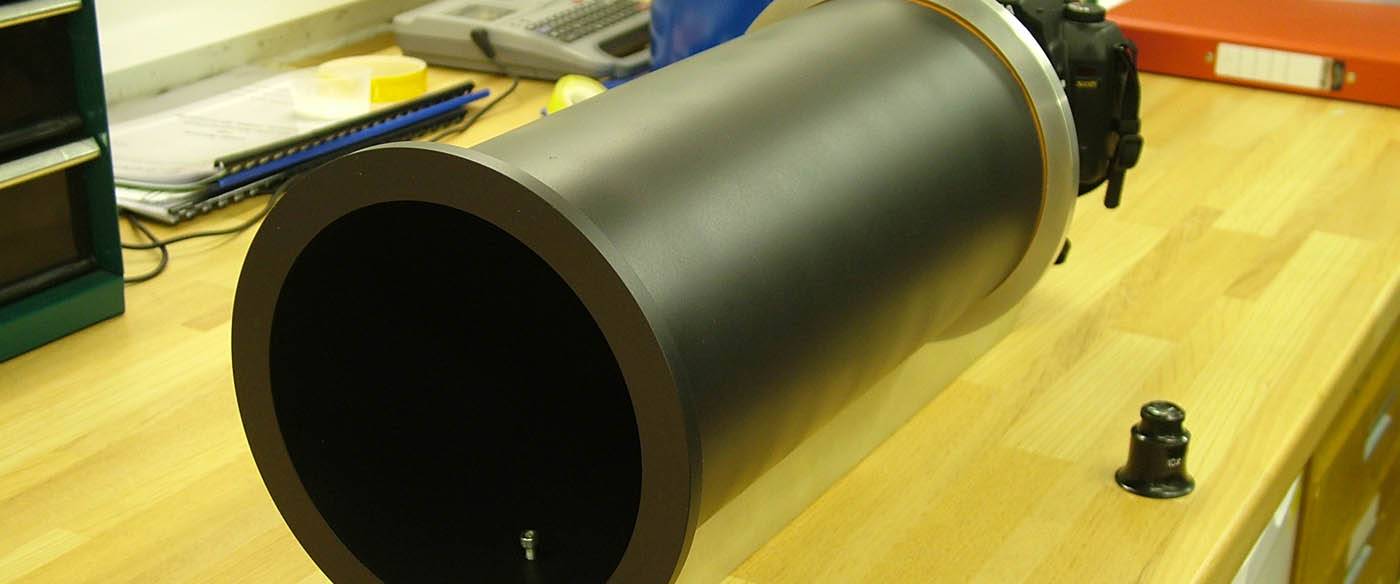

Camera tube for ground based imaging being assembled in the integration lab.

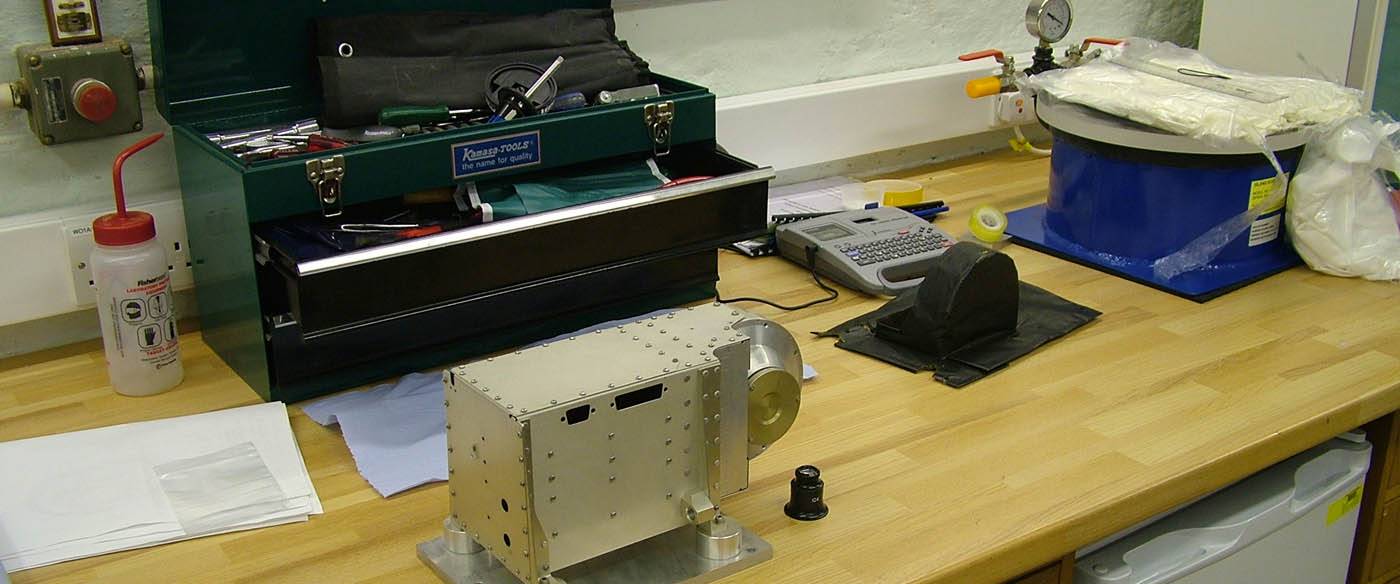

Cluster instrument housing all manufactured from flat sheet material.

The CNC Lathe in the MSSL turning shop.

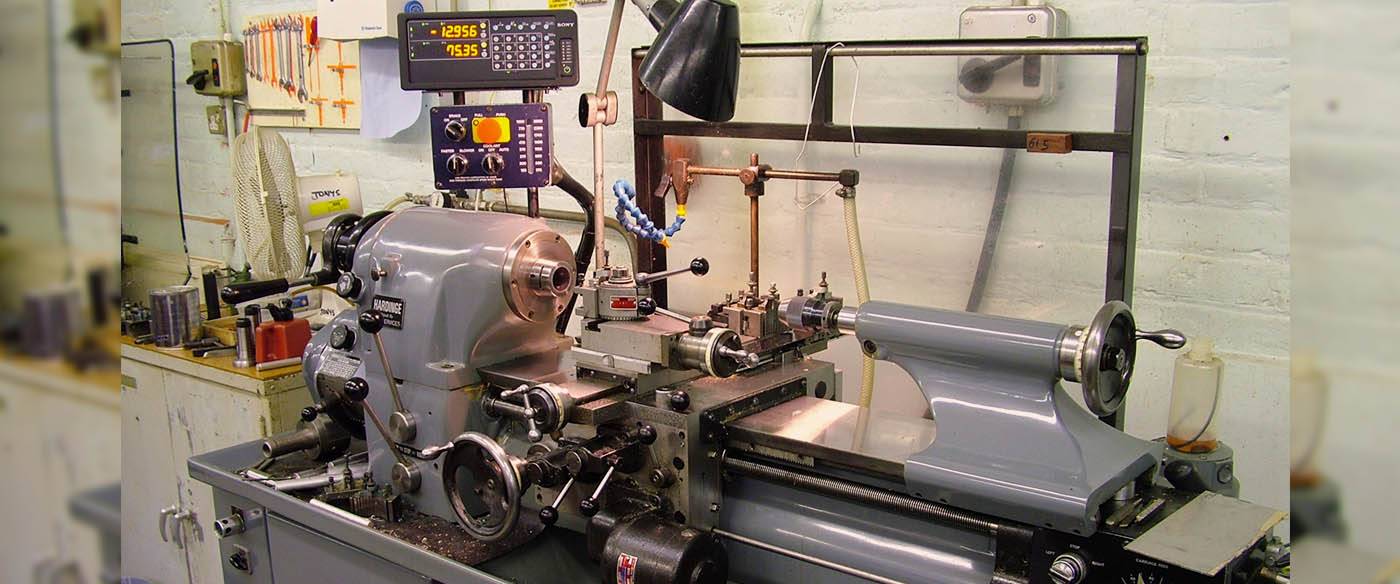

One of our high precision Hardinge manual Lathes.

Components machined in our workshops undergo a rigerous quality check during and after machining.

Capabilities include CNC and manual, milling and turning along with EDM and sheet metal forming abilities.

The engineering performed in the mechanical workshop focuses on producing specialised, high-precision low-volume parts for laboratory and space instrumentation.

Close

Close