B-made's team of staff support Bartlett exhibitions, Research and projects. Potential collaborators can review how we enable strategic activities by using the project request form on this page.

In the section:

Collaborate with B-made

Projects and Research

B-made is a multidisciplinary centre that invites collaborators to engage with new and traditional tools, processes and materials merging crafts with science and technology. B-made's powerful suite of creative and technological resources offers industrial and academic partners access to world-class resources, expertise and academic networks. The form linked below helps us assess if potential collaborations are operationally supportable within B-made's resources for Research or Projects. Please keep in mind that our team and workshop facilities need to balance these requests against existing planned projects as well as our educational commitments to our community of student users and planned teaching activities. Please share as much as possible about your proposal to help inform our feasibility discussions as we weigh research and project opportunities against our obligations to our student users.

Personal projects

Please note that B-made is primarily a teaching facility. In theory and practice, B-made is not a service provider and is founded on the premise of workshop users developing and making their own work in tandem with our team. Once trained on the relevant process, workshop users make their own projects except for certain machinery run only by staff for safety purposes. Bartlett staff who would like to access B-made resources to make personal projects are welcome to complete the B-made Induction and use B-made facilities.

Teaching activities

If you are a Bartlett Tutor, Programme Director or Coordinator, who would like to use B-made's facilties for Teaching activities, please visit our Teaching page and contact us.

Research

- Whitechapel Bell Foundary

-

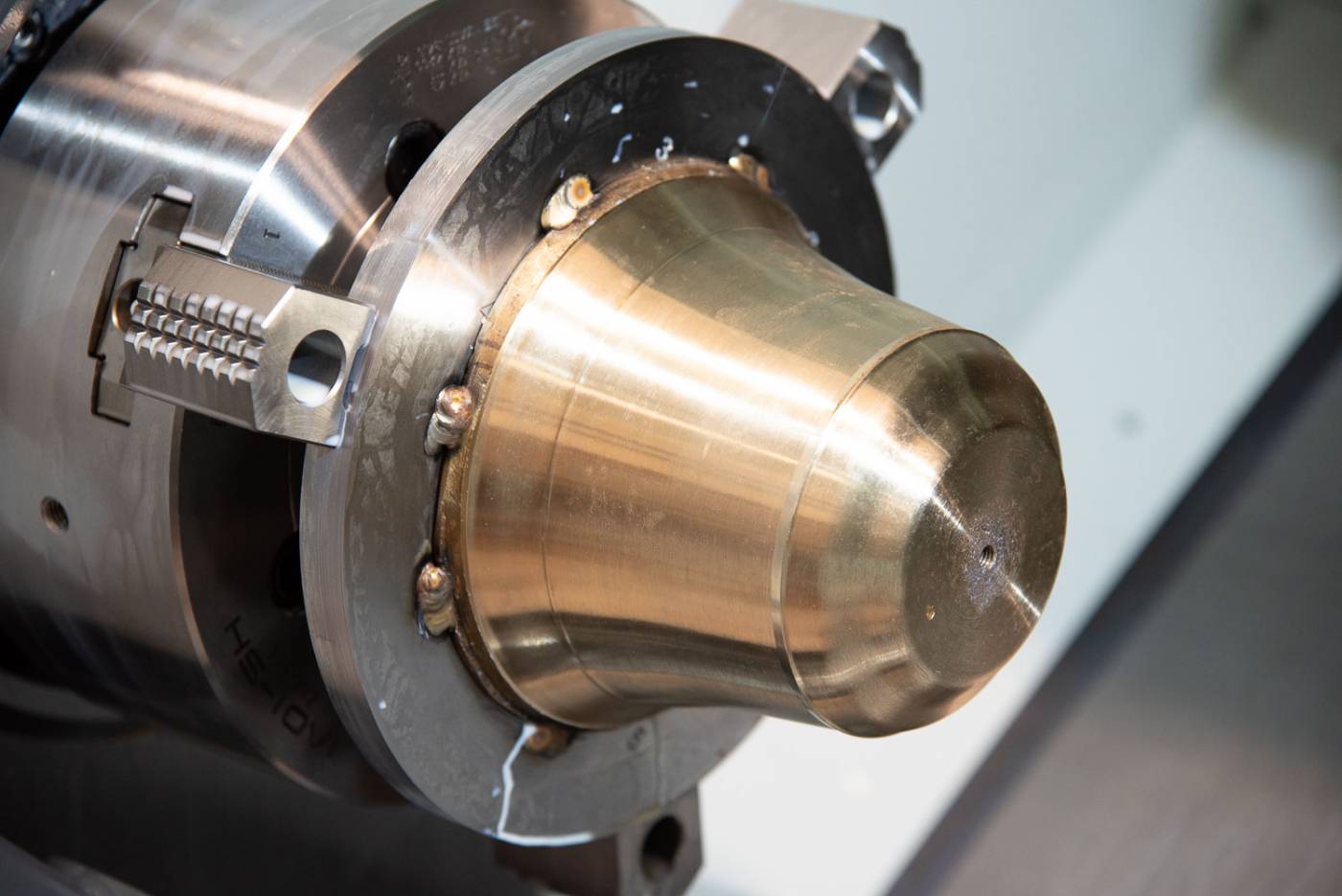

The Whitechapel Bell Foundry, located halfway between UCL’s Bloomsbury campus and UCL at Here East, Hackney Wick, was the oldest manufacturing company in Britain before it closed in 2017. The foundry’s new owners are seeking to convert it into a hotel, but the Bartlett is supporting another proposal – by the UK Historic Building Preservation Trust (UKHBPT) and the Factum Foundation – to revive the site as a working foundry, combining traditional craftsmanship with new technology and establishing an apprenticeship scheme.

Tower Hamlets Council has given planning permission for the hotel, but last month Robert Jenrick, the Secretary of State for Housing, issued a holding directive temporarily halting the plan. Peter Scully, Technical Director at B-made, said: “We wanted to do something here at B-made to celebrate the expertise at Whitechapel Bell Foundry that developed over generations and that is in danger of being lost.” Mr Scully and Melis van den Berg, Teaching Fellow at the Bartlett School of Architecture, poured melted bronze, heated to 1,200 degrees centigrade, into a hot ceramic shell, and then chipped at the ceramic to reveal the newly formed bell inside. Electric furnaces were used to heat the shell and bronze. The ceramic shell was built up in layers around a wax model of the bell. In attendance at the casting were Sufia Alam, a community leader from the East London Mosque, and Stephen Clarke, a trustee of UKHBPT.

B-made operates workshops across The Bartlett's two sites – 22 Gordon Street in Bloomsbury and UCL at Here East. Students are taught construction design using a range of technologies, from traditional woodworking to CNC milling machines and lathes to laser-cutting and robotics. The school's programmes include the 15-month Master's programmes Design for Manufacture and Design for Performance and Interaction.

Whitechapel Bell Foundry dates back to 1570. It is known for recasting Big Ben, which rings from the Elizabeth Tower of the Houses of Parliament, and for making the original Liberty Bell, a symbol of American independence. The proposal by Factum Foundation and UKHBPT would aim to restart the foundry within a year, would develop an apprenticeship and training scheme for bell making and tuning, and would open up the foundry to tours for school groups and the wider public.

- Cork House

Image: Photography by Ricky Jones

Overview

Cork House was designed by Bartlett School of Architecture alumnus Matthew Barnett Howland with Dido Milne and Oliver Wilton, The Bartlett’s Director of Technology and Lecturer in Environmental Design. Its construction was made possible through a research project which developed the cork construction system, an evolved version of which was used in the house.

Located in Berkshire, Cork House is the first building in the UK to be made of a simple new form of solid cork and timber construction. Its walls and roof are made of giant dry jointed interlocking blocks of expanded cork, a pure plant-based material with a unique ecological origin.

The house has exceptionally low whole-life carbon and is carbon negative at completion due to the atmospheric carbon stored in its plant-based components. It is easy to assemble by hand and does not require glue or mortar. Its construction enables easy disassembly at end of building life to recover its 1,268 cork blocks for reuse, recycling or simply to be returned to the biosphere. The expanded cork billets from which the blocks are formed are made in Portugal using by-products and waste from cork forestry and the cork stopper industry.

Cork House was shortlisted in 2019 for the RIBA Stirling Prize for the UK’s best new building, and has received numerous awards, including: RIBA South Award 2019 RIBA South Sustainability Award 2019 – sponsored by Michelmersh RIBA National Award 2019 2019 Stephen Lawrence Prize for the best building under £1m The research was part funded by Innovate UK and the EPSRC. UCL partnered with MPH Architects, the University of Bath, Amorim UK and Ty-Mawr on the project, with contributions from consultants Arup and BRE.

All the cork blocks for the research project were made at The Bartlett Manufacture and Design Exchange (B-made), using a robotic milling method developed specifically for the project.

Contractor: Matthew Barnett Howland (assisted by M&P London Contractors Ltd)

Executive Architects: MPH Architects

Structural and Fire Engineer: Arup

Whole Life Carbon Assessment: Sturgis Carbon Profiling LLP

Cork Fabrication Research: B-Made at The Bartlett UCL

Cork CNC Machining: Wup Doodle- Changemakers

Through this ChangeMakers project, a remote learning course was conducted and a process guide was developed on robotic 3D printing of ceramics. This project looked at Enabling remote and independent learning in the workshop environment. Ten students participated in the three day remote online course to design and create ceramic prototypes using robotic 3D printing process. Parameters, potentials and limitations of the process are documented as a guide substantiated through experiments. The process guide was developed by the student collaborators from the school of architecture and was steered by a team of supervisors who specialize in ceramic printing and robotic manufacturing.

14 Sept 2021

- Case study by: Pradeep Devadass

- Staff: Ben Lee, Sienna Griffin-Shaw, Georgios Drakontaeidis

- Students: Finn Shi, James Robinson

Projects

- 2019: Arup, Drivers of Change: New forms of practice from The Bartlett School of Architecture

15 July – 13 September 2019

This exhibition showcases cutting-edge research from three pioneering master’s programmes at The Bartlett School of Architecture, UCL: Design for Manufacture, Bio-Integrated Design and Design for Performance and Interaction.At a time of climate crisis, the interdisciplinarity of the master’s programmes, for example, applied biology and architecture, encourages students to develop radical new alternatives for tackling the different complex environmental challenges faced by contemporary urban society.

The exhibition also marks the launch of the latest edition of Drivers of Change, a publication developed by Arup’s Foresight team to raise awareness about global issues affecting the future of the built environment, such as depleting natural resources and the need to improve urban food systems. The exciting new forms of practice from The Bartlett propose groundbreaking ways of addressing these issues: they are a taste of things to come.

- 2016: Royal Academy, The Veronica Scanner; Live 3D portraiture

Image © David Parry

2 September — 11 September 2016

In 2016, B-made supported the robotic milling of 3D portraits for the interative project 'The Veronica Scanner'. Visitors' images were captured using photogrammetry and B-made's onsite team helped fabricate milled busts of the visitors and other historical figures.

The Veronica Scanner is a project by Factum Foundation, whose previous work includes a scan of Tutankhamun’s tomb in Luxor, Egypt and a re-materialised copy of Caravaggio’s Nativity with Saint Francis and Saint Lawrence in Italy. Factum Arte, the workshop in Madrid that built the scanner and from which the Foundation emerged, has worked with a number of Royal Academicians including Anish Kapoor, Grayson Perry, Conrad Shawcross and Gillian Wearing.

Bartlett Exhibitions

B-made project management delivers the physical components of The Bartlett's student exhibitions every year. The team collaborate with student and staff stakeholders to create the exhibition armiture and integration of student work in collaboration with the Director of Exhibtions.

Close

Close