UCL, UCLH and Formula One develop life-saving breathing aids

17 April 2020

A breathing aid developed by engineers at UCL and clinicians at UCLH working with Mercedes-AMG High Performance Powertrains is being deployed in NHS hospitals to help Covid-19 patients breathe more easily.

The breathing aid, known as Continuous Positive Airway Pressure (CPAP), has been used extensively in hospitals in Italy and China to help Covid-19 patients with serious respiratory problems, when oxygen via a face mask is insufficient.

CPAP devices are in short supply in UK hospitals, so engineers at UCL and Mercedes-AMG HPP worked round-the-clock to reverse engineer a device that could be manufactured rapidly by the thousands. This was achieved in a rapid timeframe – it took fewer than 100 hours from the initial meeting to production of the first device. The device was then further refined to consume up to 70% less oxygen.

Following approval by the regulator, MHRA, the UK Government placed an order for up to 10,000. These were manufactured at the HPP technology centre in Brixworth, Northamptonshire, and deliveries have now begun to hospitals across the NHS network.

To help meet international need, the designs and manufacturing instructions have been made freely available to governments, manufacturers, academics and health experts across the globe. As of 15 April, these instructions had been downloaded from covid19research.uclb.com/product/ucl-cpap by 1,445 approved teams in 105 countries.

UCLH critical care consultant Professor Mervyn Singer (UCL Medicine) said: “These devices will help to save lives by ensuring that ventilators, a limited resource, are used only for the most severely ill.

“We and others are finding that a significant proportion of patients treated with CPAP can avoid mechanical ventilation.”

Professor Rebecca Shipley, Director of UCL Institute of Healthcare Engineering, said: “At UCL, we have an established ecosystem of partnerships spanning engineers, healthcare and industry ready to be mobilised in times of need. It’s been a privilege to work closely with our clinical colleagues and with doctors leading the Covid-19 response in China and Italy. This close contact has helped us to define the need and respond with technology that we hope will support the NHS in the weeks and months to come.”

Professor Tim Baker (UCL Mechanical Engineering) said: “Given the urgent need, we are thankful that we were able to reduce a process that could take years down to a matter of days.

“From being given the brief, we worked all hours of the day, disassembling and analysing an off-patent device. Using computer simulations, we improved the device further to create a state-of-the-art version suited to mass production.

“We were privileged to be able to call on the capability of Formula One – a collaboration made possible by the close links between UCL Mechanical Engineering and HPP.”

Professor David Lomas (UCL Vice Provost Health) said: “These life-saving devices will provide vital support to the NHS in coming weeks, helping to keep patients off ventilators and reducing demand on intensive care beds and staff. We believe they can also make a real difference around the world in supporting healthcare systems preparing for Covid-19.”

Professor Michael Arthur, UCL President & Provost said: “This demonstrates what extraordinary things can be achieved when universities, hospitals and industry work together for the national good. These devices, which can play a vital role in keeping patients out of intensive care, have been produced in just a couple of weeks as a result of the close collaboration between UCL, UCLH and HPP. The UCL community is incredibly proud of the entire team behind this breakthrough.”

UCLH Chief Executive Marcel Levi said: “This is a real team effort and I am proud of colleagues at UCLH and our partners at UCL and HPP for their immense work to produce this device in such a short time. We hope this effort can be rolled out to hospitals across the UK to benefit all patients.

“Everyone involved in this project should know that their efforts will have a truly significant impact on patient care.”

Professor Bryan Williams, Director of the NIHR Biomedical Research Centre at UCLH, said: “This is a fantastic example of collaboration across the UK life sciences and industry sector that could only have happened this quickly because of the partnerships the BRC has cultivated over many years.”

Andy Cowell, Managing Director of Mercedes-AMG High Performance Powertrains, said: “Since the project was announced, we have received an incredible number of enquiries about the CPAP device from around the world. Making the design and manufacturing specifications openly available will allow companies around the world to produce these devices at speed and at scale to support the global response to Covid-19.”

Andy Obeid, Chief Executive of Oxford Optronix, a small business that will manufacture the oxygen monitors for the CPAP devices, said: “By working flat out and mobilising the support of every individual in my company as well as other small companies across the UK, we have accomplished something in five days that would normally take two years.

“I am delighted we have been able to design, develop, test and manufacture a bedside monitor that will continuously measure the concentration of oxygen being delivered to the patient and is ready for clinical trials.”

CPAP machines are routinely used by the NHS to support patients in hospital or at home with breathing difficulties. They work by pushing an air-oxygen mix into the mouth and nose at a continuous rate, keeping airways open and increasing the amount of oxygen entering the lungs. Invasive ventilators deliver breaths directly into the lungs, but require heavy sedation and connection to a tube placed into the patient’s trachea (windpipe).

For more information, visit the UCL-Ventura breathing aids website.

Links

- UCL-Ventura breathing aid – design and manufacturing package

- Professor Rebecca Shipley’s academic profile

- Professor Mervyn Singer’s academic profile

- Professor Tim Baker’s academic profile

- UCL Mechanical Engineering

- UCL Institute of Healthcare Engineering

- UCL Engineering

- UCL Medicine

- UCL Medical Sciences

- UCL President & Provost

- Office of the Vice Provost (Health)

- UCLB

- Mercedes-AMG High Performance Powertrains

- UCLH

- NIHR UCLH Biomedical Research Centre

- Oxford Optronix

- Project Pitlane

Image

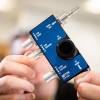

A volunteer ‘patient’ with the newly developed CPAP device. Credit: James Tye / UCL

Media contact

Mark Greaves

Tel: +44 (0)7539 410 389

Email: m.greaves [at] ucl.ac.uk

Close

Close