Electronic Workshop

The Electronic Workshop (EWS) undertakes the construction of flight electronic assemblies, wiring harnesses and complex bespoke scientific instruments. Most of the assemblies are based on high density PCBs with an increasing amount of surface mount components.

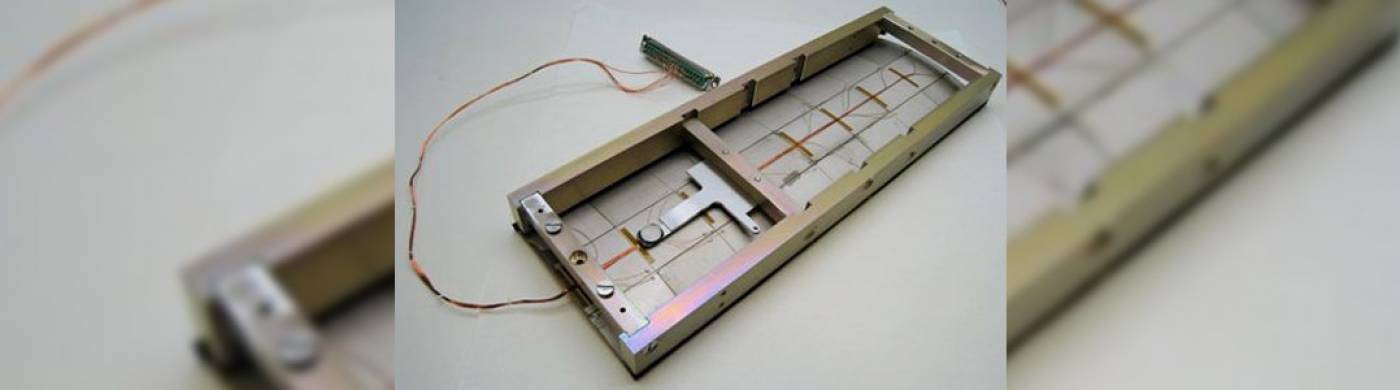

Deformable X-RAY mirrors assembly

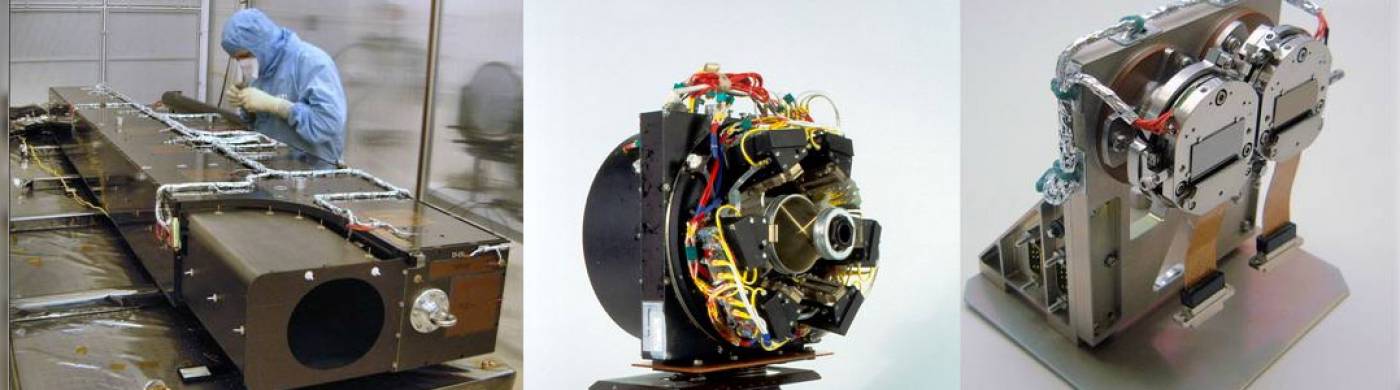

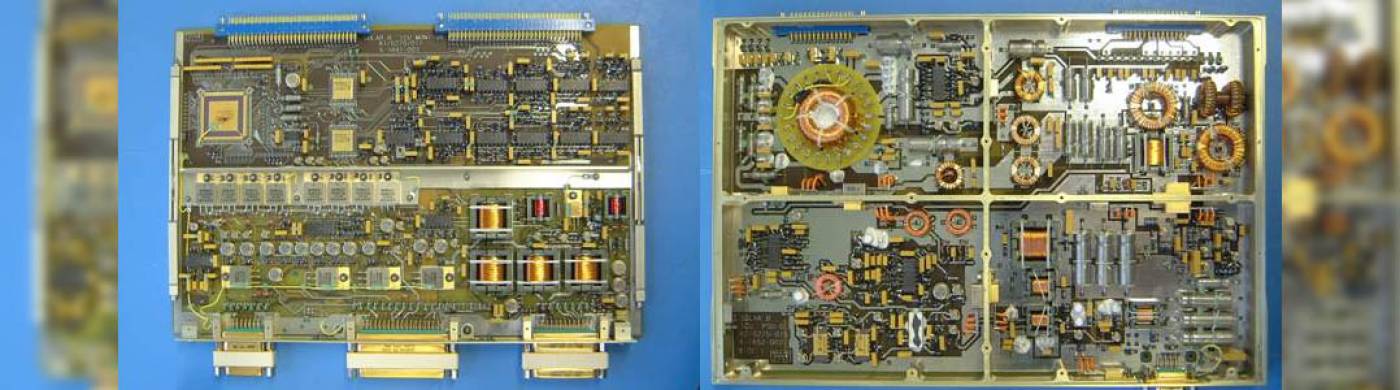

Solar-B flight outer harnessing - Mars Express Fonema instrument - Solar B CCDS focal plane assembly

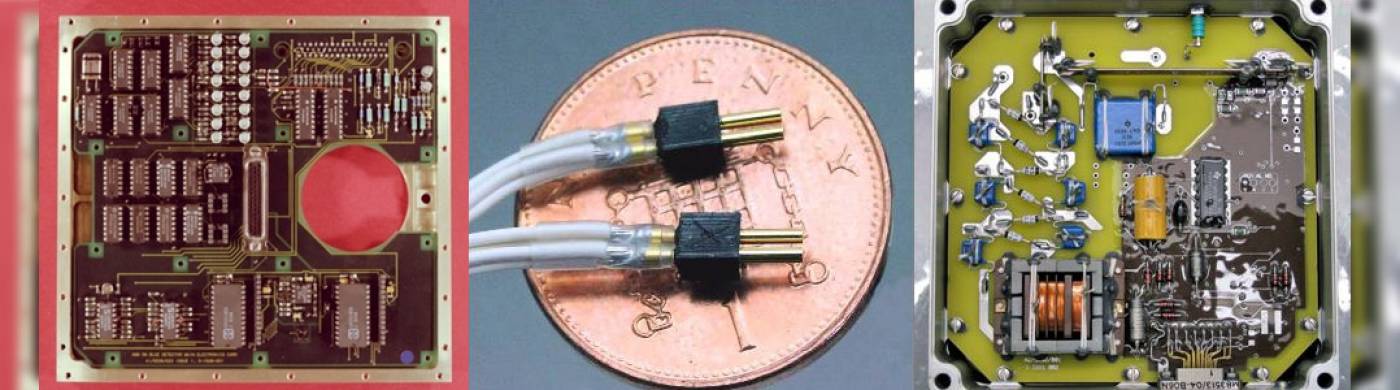

XMM OM camera board PCB - JWST NirSpec CAA connector detail - UVIT HV generator PCB

SXO HV wires soldered to laser cut piezoelectric actuators with pure indium and NirSpec CLS OGSE bulb test at cryogenic temperatures

JWST NirSpec CAA harness detail and JWST NirSpec CAA harness overview

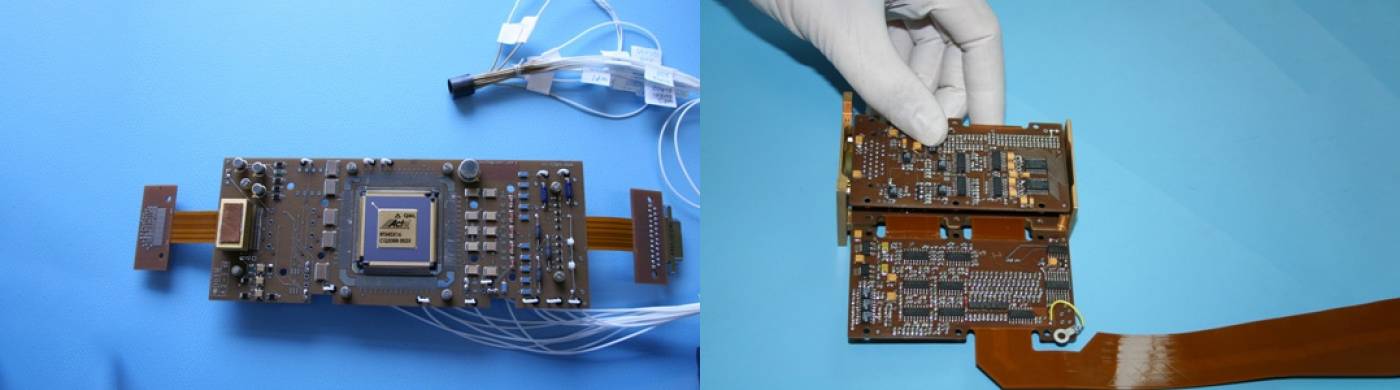

Fight harness contamination control and Solar B ICU PROC digital board

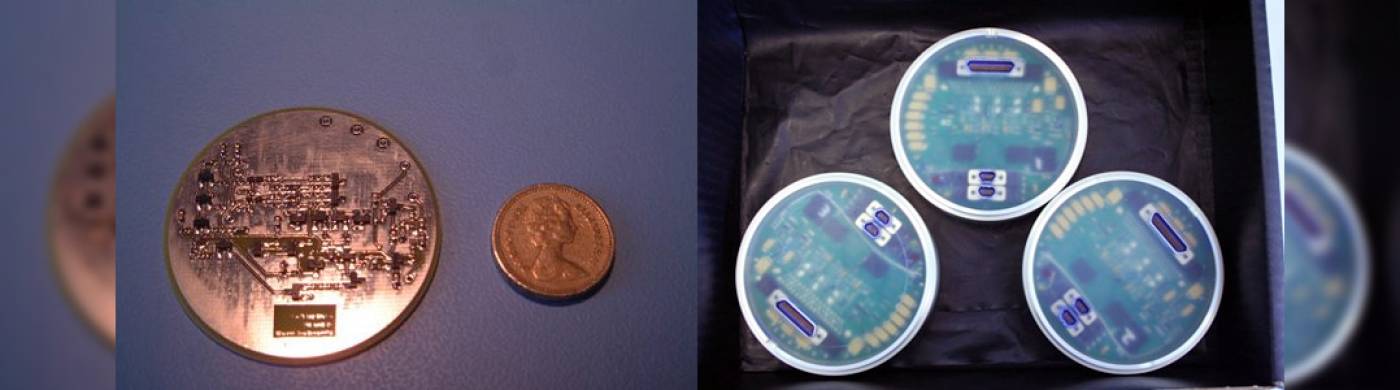

Airless Penetrator electronics modules and Super Nemo Preamp PCB

Solar B Monitor PCB and Solar B ICU PSU

ExoMars Environmental testing and GAIA PEM industry model

Due to the low volume, exceptional component cost and very high standards of work required PCB assembly is carried out using a mixture of proven manual techniques and surface mount assembly machines in a controlled environment laboratory. Technical staff have all undertaken ESA training for hand soldering, PCB modification and rework, surface mount assembly, inspection, crimp wiring construction and are re-certified every 2 years.

Electronic Engineering:

Head of Electronics

Gary Davison

+44 1483 204 116

g.davison@

Close

Close