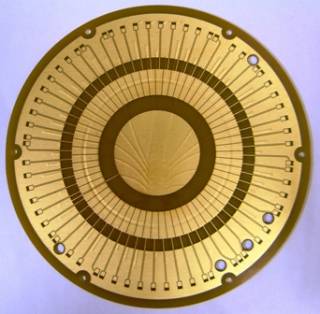

The main task of the Electronic Drawing Office (EDO) is the layout of printed circuit boards (PCBs) followed by the production of the manufacturing and assembly drawings.

Very experienced layout draftsmen, use market leading electronic design automation (EDA) tools ('Expedition' from Mentor Graphics Corporation) to produce layouts to the high quality assurance standards required by major space agencies for large and long duration missions. An in-house set of PCB layout design rules are used, based upon those published by the major space agencies, but modified to reflect the detailed requirements of each mission. Most of the PCBs designed are conventional rigid multilayer glass fibre boards but a considerable number of flexi-rigid and a smaller number of fully flexible boards are designed. Novel techniques have been used to meet the unusual requirements of some instruments, such as forming boards into a cylindrical shape and 'Z-folding' flexible boards.

Over the last 40 years, the Electronic Drawing Office has produced more than 700 PCBs designs, most of which have been used to support flight missions. There are about 100 of our PCBs being used in space today!

Close

Close