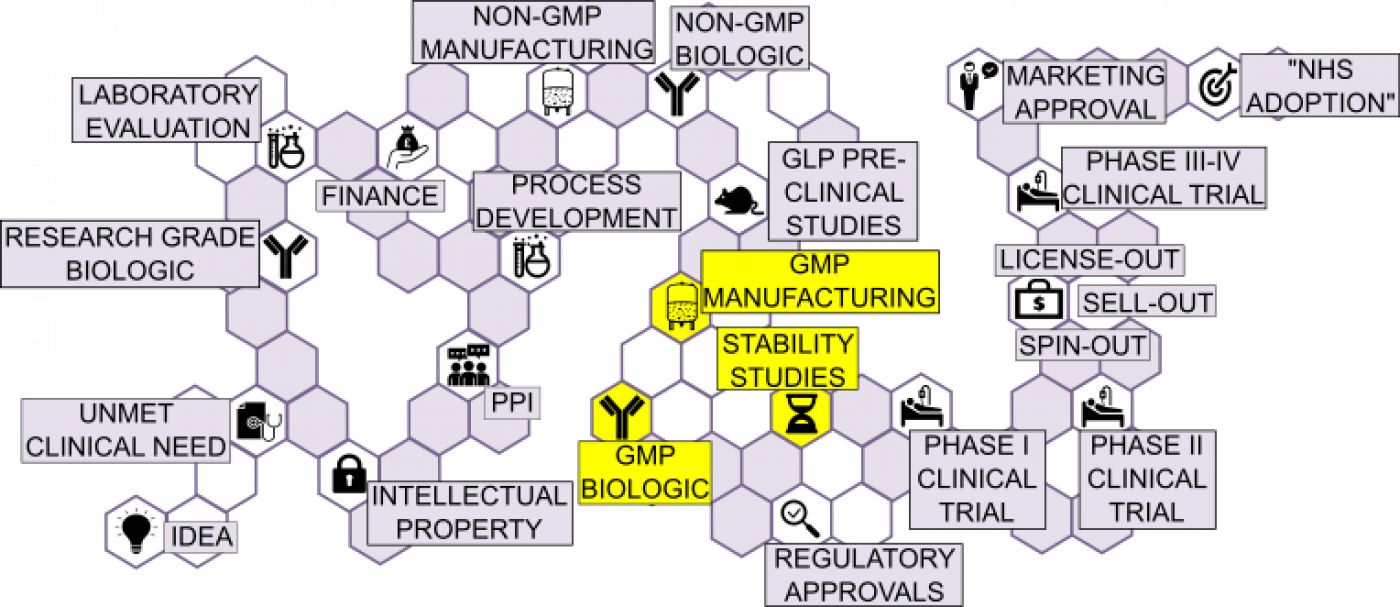

Good Manufacturing Practice (GMP) and stability data are essential to develop a biologics product suitable for a clinical trial.

GMP-MANUFACTURING:

GMP-MANUFACTURING:

Considerations - Batch manufacture to GMP compliance; Suitable product for clinical studies; Fill finish requirements; Reference standards for lot to lot comparison.

GMP-BIOLOGIC:

GMP-BIOLOGIC:

Considerations - Fit-for-purpose/meets TPP; Meets release criteria; QP release by fill/finish QP; 3 months of stability data required for IMPD/CTA.

UCL Support:

The UCL Translational Research Group (TRG)'s expertise and knowledge of the biologics field means that they know which GMP manufacturers are in the best position to help you to start the conversation with them.

STABILITY STUDIES:

STABILITY STUDIES:

Stability studies for biologic therapeutics are crucial in order to assess sensitivity to factors which could impact biologic activity, product safety and quality during storage.

Stability studies must:

- Be real time/real temperature (for 5 yrs) and accelerated studies (for 12 months)

- Be in relevant container / at relevant volume

- Be upright and inverted containers for RT/RT studies

- Utilise appropriate validated assays to verify physicochemical properties and purity, identity, potency, concentration, dosage form (product) properties and safety of biologic throughout study.

UCL Support:

Specifically the Translational Research Group (TRG) within the UCL TRO, have experience in supporting UCL biologics projects, using their knowledge to advise researchers on stability study design for therapeutic biologics.

Close

Close