Bartlett Manufacturing and Design Exchange (B-Made) provides online content for connected learning

B-Made provides digital resources, themed by process or material area, to enable students to continue learning remotely during Covid-19.

8 June 2020

B-made (The Bartlett Manufacturing and Design Exchange) is made up of a team of staff and educational manufacturing facilities (workshops) usually located across two sites within The Bartlett School of Architecture’s locations at 22 Gordon Street in Bloomsbury and UCL at Here East.

B-made operates workshops as multidisciplinary centres. Bartlett Faculty staff and students, and UCL Here East partners use B-made for their projects, from concept and design stages through to completion. B-made's aim is to merge crafts and manufacturing with science, technology and design, shifting towards new models of learning.

What support is B-made offering?

B-made is catering their online tools to try and anticipate the new ways of working students will be adapting to while working from home. The online resources will vary by process or material area, but there are many considerations, experiences and technical knowledge that B-made can still share with students remotely that can help with projects.

B-made staff are proactively covering a spectrum of digital resources aimed to help students - from CAD troubleshooting and best practice guides, robot animations and other CAD support, to material readers and analogue 'Making at Home' guides with helpful tips and tricks on how to model with materials you can get in the grocery store.

This development of a Connect Learning strategy for B-made will provide digital resources that can help students get a deeper understanding of processes, materials and methods of making, inspire research questions and address issues around sustainability that usually get side-lined in the rush to produce something physically.

B-made is building the online materials with five key practical guidelines:

- Cater to the current circumstances in the context of COVID 19;

- Ensure that the content is of value and relevant outside of the context COVID 19;

- Provide practical support with 'how to' guides that do not necessarily require physical outputs or B-made equipment;

- Provide theoretical support with 'why to' guides that address pedagogical ideas around making and manufacturing;

- Offer unique Connected Learning tools that are bespoke and curated for the Bartlett Audience.

B-made is still there for students every weekday from 10am-5pm (UK Time) to make sure students can still continue having important discussions and Process Tutorials with the team in real-time. A schedule has been established and students can book a session with a Technician or Teaching Fellow on the Moodle page. The staff member then calls the student via Teams at the scheduled time.

A ‘Lunchtime Lecture’ series was also established during the standard lunch hour, 1pm (UK Time) each Thursday; A member of the B-made team then broadcasts a live lecture over Blackboard for students to tune into with a question/answer period at the end. This has had consistent viewership of approximately 60 students each Thursday. Lectures are recorded and hosted on the Moodle page for those who cannot make the live lectures.

Summary of Connected Learning Content

Online now

Making at Home

- Photography guide: Shooting at home with natural light and limited equipment.

- Photogrammetry Part 1: A guide to taking photos for 3D imaging.

- Photogrammetry Part 2: A guide to using Agisoft software for processing photos.

- Gluing guide: a comprehensive guide to glue and how to make your own.

- Unconventional materials and model making hacks - video tutorial

See an example of our working from home guides.

Lunchtime Lecture Series

- Live each Thursday at 13:00 throughout Term 3

- Lectures are recorded and then saved on the ‘Lunchtime Lectures’ tab of the ‘B-made Online’ Moodle.

See how we advertise our bookable sessions.

CAD tutorials

The team has compiled a series of 13 videos to help students with issues the team commonly see students face:

- Modelling with Curves: 2 videos

- Modelling with Surfaces: 5 videos

- Tips and Tricks: checking data quality video

- Tips and Tricks: things to check before exporting .STL files

- Tips and Tricks: reducing file sizes

- Tips and Tricks: rebuilding geometries

- Tips and Tricks: removing duplicates

- Tips and Tricks: reducing meshes

See an example of our CAD tutorials.

Material Primer: Wood

- Intro to wood (video)

- Interactive online reader

- species guide.

See an example of a content primer.

Coming up (works in progress)

- Robot animations: Video tutorials on how to run robots (virtually)

- Textiles: Using fabric from 2D visualisations

- Casting and mould making

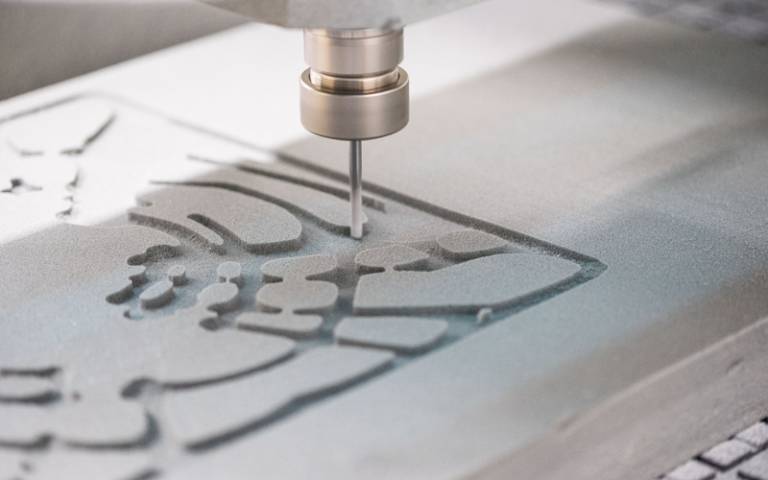

- 2D CNC outsourcing guide

- Material Primer: Metal

- Material Primers: more interactive readers and resources about materials (plaster, glass, ceramic, plastic etc.) Different than the Institute of Making's approach to materials with a focus on practical applications and processes, history, production and sustainability

- Robot fundamentals: Essential thinking around robotics.

- CNC fundamentals: Essential thinking around CNCs

- And more!

Close

Close