The dirty truth about procurement

21 September 2022

For many organisations, the greenhouse gas emissions associated with their procurement is likely to take up the largest share of their total carbon footprint. At The Bartlett, we’re looking at how to effectively understand and reduce our procurement emissions.

By Nick Hughes, Bartlett Faculty Lead for Climate Action and Blanche Cameron, Environmental Design Lecturer at The Bartlett School of Architecture

When we think about the largest causes of our greenhouse emissions, our thoughts often turn first to the energy we use directly – to heat, cool and light our buildings, or to enable our travel.

However, another significant portion of our carbon footprint is accounted for by the products and services we buy – what organisations call “procurement”. Indeed, for many organisations, the greenhouse gas emissions associated with their procurement is likely to take up the largest share of their total carbon footprint.

This certainly seems to be the case for UCL as a whole. Data available from the Higher Education Statistics Agency (HESA) suggest that UCL’s supply chain procurement would typically account for the largest share of its total emissions. A more detailed analysis of these statistics can be found in our recent procurement progress report.

Such UCL-level estimates provide a useful guide, indicating the likely significance of procurement emissions for The Bartlett. However, the procurement activities of UCL are not directly scalable to The Bartlett, which is characterised by particular sets of activities that will lead to its own particular procurement profile. In order to understand better our procurement emissions and identify priority areas for action, we need to examine our own data and build up our own Faculty-level estimates.

This is not a straightforward task. Procurement covers a wide range of products and services, which for The Bartlett includes:

- IT products

- Furniture

- Stationery

- Food and hospitality

- Workshop materials

- Specialist machines

- Laboratory equipment

In each of these categories, the emissions associated with particular products need to be estimated on a “life cycle” basis, including emissions that may arise from the sourcing of raw materials to make the product, its manufacture, distribution, use and disposal. The complexity is such that almost any quantification of procurement carbon footprint is likely better regarded as an “estimate” than a final answer. Nonetheless, by continually refining our data sources and methods we can progressively reduce the uncertainties and get closer to the true value.

Our efforts to improve our understanding of the emissions created by The Bartlett’s procurement activities have been crucially supported by collaborations between staff acting in a variety of roles, and students. Colleagues in finance, procurement, and other professional services divisions, including Ian Galloway, Farhana Zaman, Samina Miah and Philippa Shallard, helped to supply details of purchases made by the Faculty. Students India Goodwin and Tshiamo Ramano (2021), and Ying Cai and Berill Takacs (2022), with the support of Dr Isabela Butnar and Dr Aiduan Borrion, have combined this data with information from life cycle assessment studies to estimate Bartlett-specific values for procurement emissions.

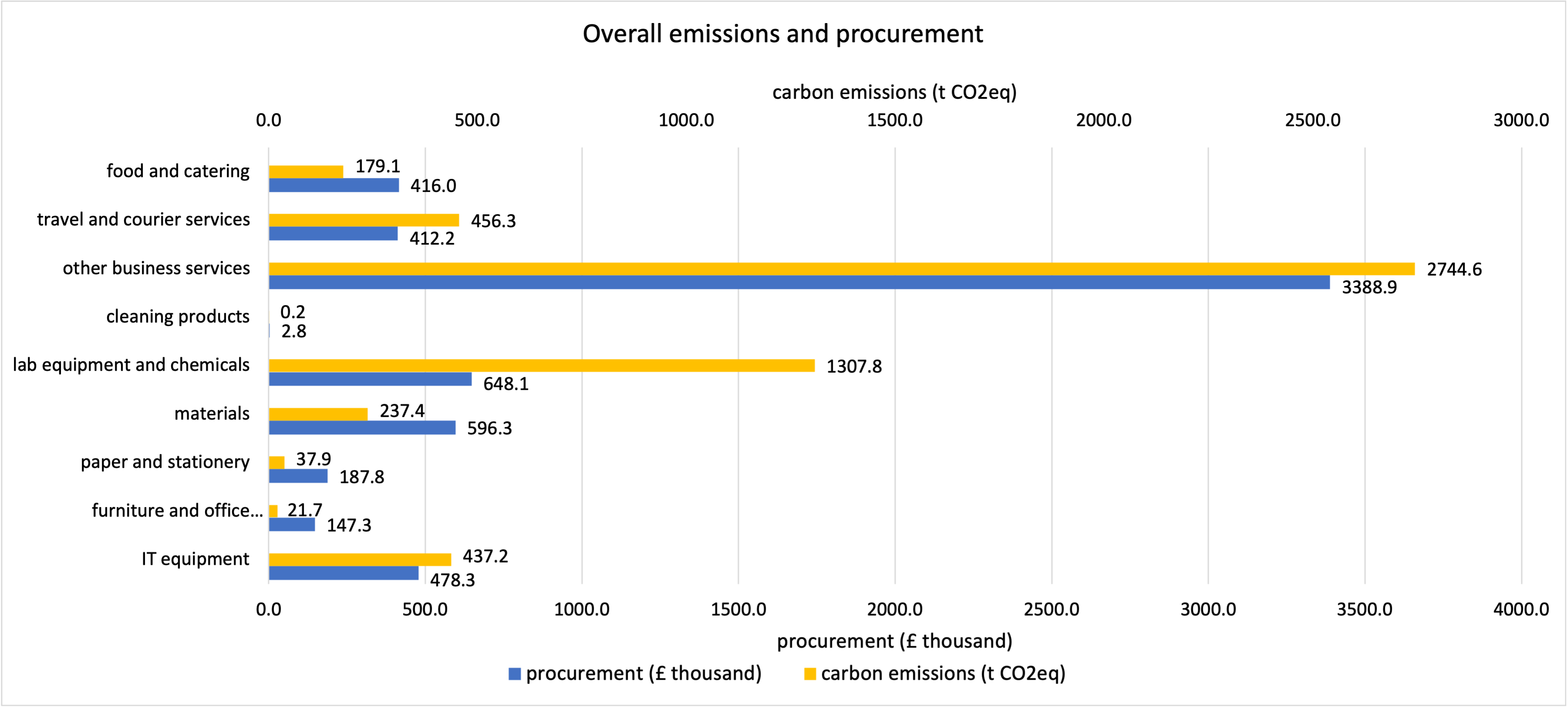

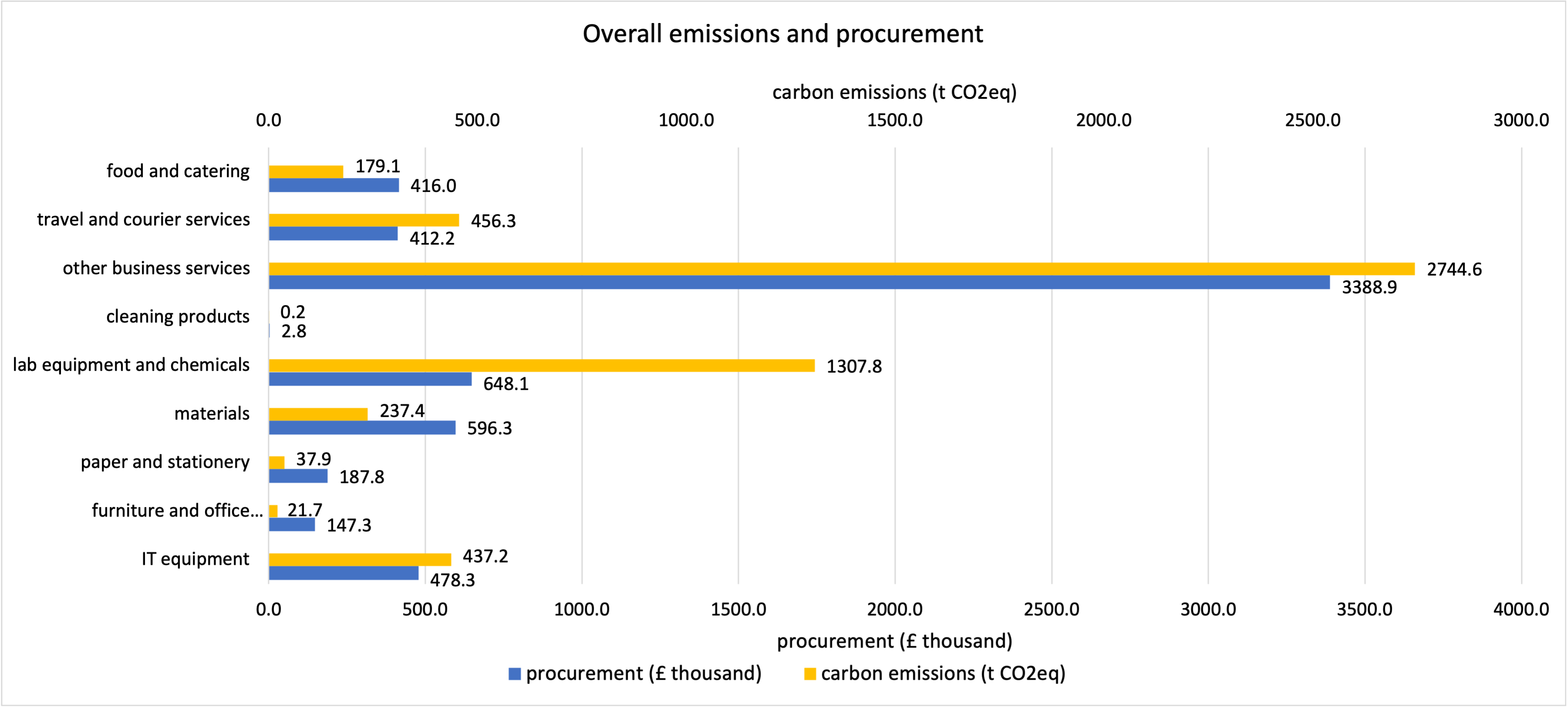

The Figure below provides an initial overview of estimated Bartlett procurement emissions for the financial year 2018-19, as calculated by Ying Cai.

Procurement spend (£ thousand) and estimated life-cycle carbon emissions (tCO2eq) for the Bartlett, financial year 2018-19. Source: Cai (2022) Life cycle assessment for carbon emissions from procurement of UCL Bartlett.

Procurement spend (£ thousand) and estimated life-cycle carbon emissions (tCO2eq) for the Bartlett, financial year 2018-19. Source: Cai (2022) Life cycle assessment for carbon emissions from procurement of UCL Bartlett.

These calculations are preliminary, and involve some assumptions and approximations due to unclear or incomplete data. Nonetheless, they begin to offer more specific information about procurement emissions at the Bartlett level. According to these calculations, the largest category, accounting for just over 50% of emissions, is “other business services”; however further work is needed to verify the appropriate specific emissions factors for these various services, which range from online subscriptions to accommodation on work and study trips. The next biggest category is lab equipment and chemicals, which is notably more carbon intensive per pound spent than the other categories and accounts for about 24% of total emissions. Travel and courier services, and IT equipment, are also significant contributors, followed by materials, food and catering, and other smaller contributors.

Thus, through the excellent work of our students, we are beginning to understand with greater clarity the current state of our procurement emissions. We will continue to refine our data and calculation methods, in order to increase the reliability of our estimates of these emissions.

One way in which we can all help to increase our understanding of our procurement emissions is by adding as much detail as possible about a product (for example, make and model) or service (for example location, destination, number of people) when making purchases. The more detail is available in the financial records, the more precise our emissions estimates can be.

At the same time, we are also beginning to explore measures that will help us reduce our procurement emissions.

Considering the carbon footprint of items to inform purchasing decisions

As found by Goodwin and Ramano in the case of laptops, there can be considerable variation in the carbon footprint of apparently relatively similar products. If we were provided with relevant information on the carbon footprint of available options, we could take this into account when faced with a purchasing choice. IT equipment could be one area for such an approach.

Using our research to create a toolkit for purchasing materials used in workshops

A research team* of ten undergraduate and postgraduate students from across programmes at The Bartlett School of Architecture has been exploring the school's materials culture in relation to embodied carbon, waste/reuse and other sustainability and social criteria of materials. The team developed a survey that received opinions from over a hundred staff and students on sustainable materials teaching and learning, practical making and sourcing and on questions and proposals for changes in The Bartlett School of Architecture.

Their report will recommend practical actions to improve the understanding of staff and students about the environmental and social impacts of workshop materials, while still supporting learning and research in the fullest sense. Sustainability information is needed on materials supplied through the B-Made workshops and elsewhere, for example via a traffic light system that can be quickly understood in terms of embodied carbon, ecological footprint or other criteria. There is also an opportunity to broaden and embed sustainable materials teaching and learning across the school, for example, more hands-on materials workshops, discussions and sharing between programmes, to explore the impacts of materials and options for healthier, more equitable or regenerative choices. Building on this research, the next steps could also include the development of a Bartlett School of Architecture Sustainable Materials Strategy, as part of The Bartlett’s Journey to Net Zero by 2030. There are also opportunities to connect with other institutions (the team are now connected with a related research team at the RCA) and networks both within UCL such as the Institute of Making and Sustainable UCL, and the wider profession, including ACAN, LETI and others.

The Bartlett School of Architecture research team on sustainable materials.

The Bartlett School of Architecture research team on sustainable materials.

The team’s report is due to be published and shared soon as part of the Bartlett Faculty's work on the Journey to Net Zero 2030.

Working with product suppliers that support our mission

We should also look to work with our product suppliers to develop relationships that support increased material “circularity” – that is, the reuse or remanufacturing of products, or components from products, extending the useful lifetime of materials and significantly reducing life cycle emissions. As found in another student report by Nyma Haqqani, several of the major IT manufacturers have ambitious net zero targets, with material circularity a key contributing strategy. We should engage with our suppliers to take up these opportunities.

In the area of office furniture, one of UCL’s preferred suppliers, JPA, has a net-zero target by 2030, with circularity a central part of this. JPA is active in supporting the reallocation of furniture within the UCL estate, and in supporting repair and refurbishment.

JPA are keen to ensure that the carbon reduction benefits of using reused or refurbished furniture is communicated back to users. Two of our students worked with JPA to produce labels that could be attached to items of furniture to communicate these benefits. One of Elisa Martini’s designs is shown below. The design draws focus toward the slogan and QR code, with a call-to-action on the sides of the QR code to encourage users to access the information on the scheme. The text of the slogan is slightly mysterious which can intrigue users. Additionally, using natural imagery creates a perception of positive climate impact.

Design for sustainable furniture label – Elisa Martini. Refurbished Label © 2022 Elisa Martini licensed under CC BY 4.0

Design for sustainable furniture label – Elisa Martini. Refurbished Label © 2022 Elisa Martini licensed under CC BY 4.0

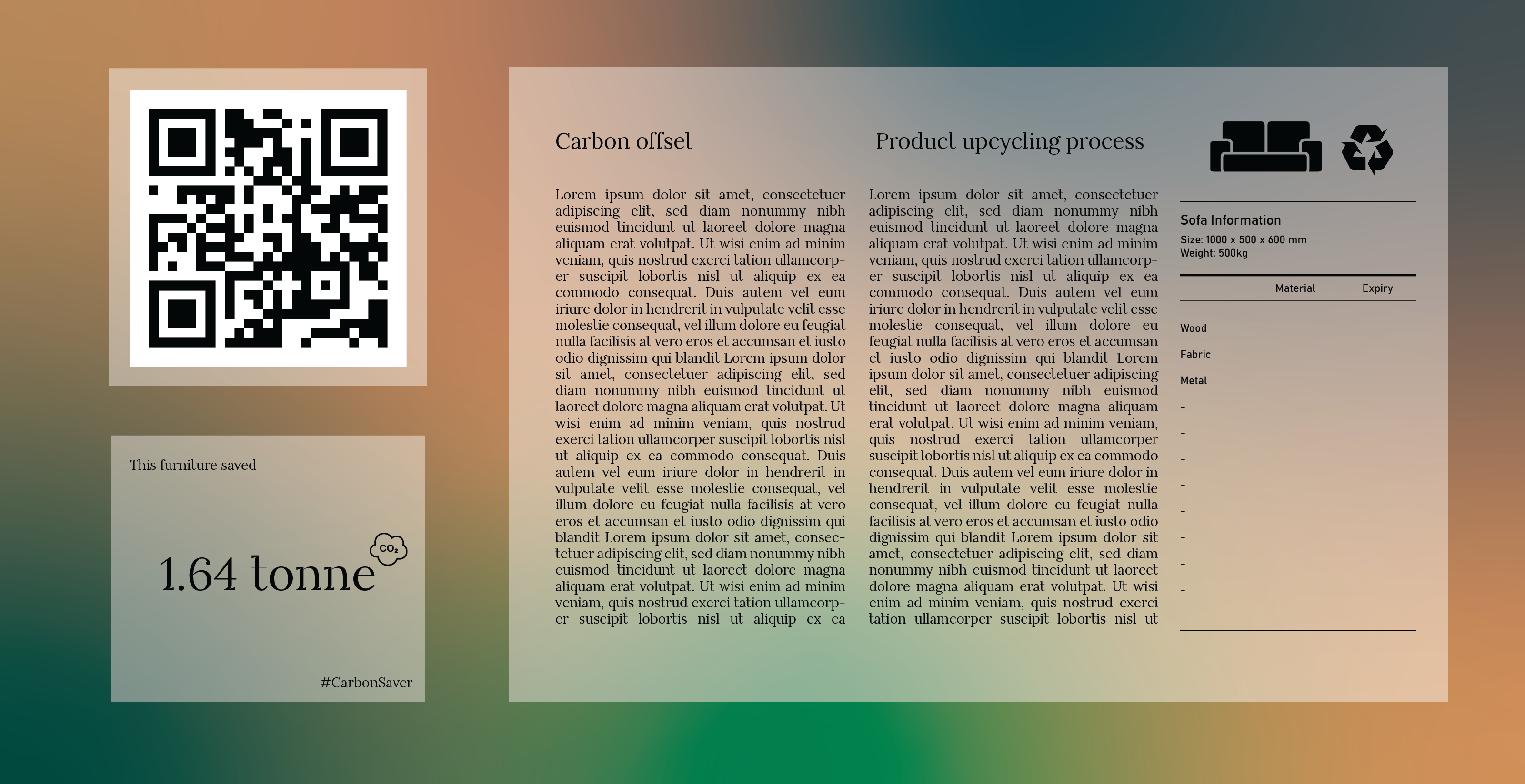

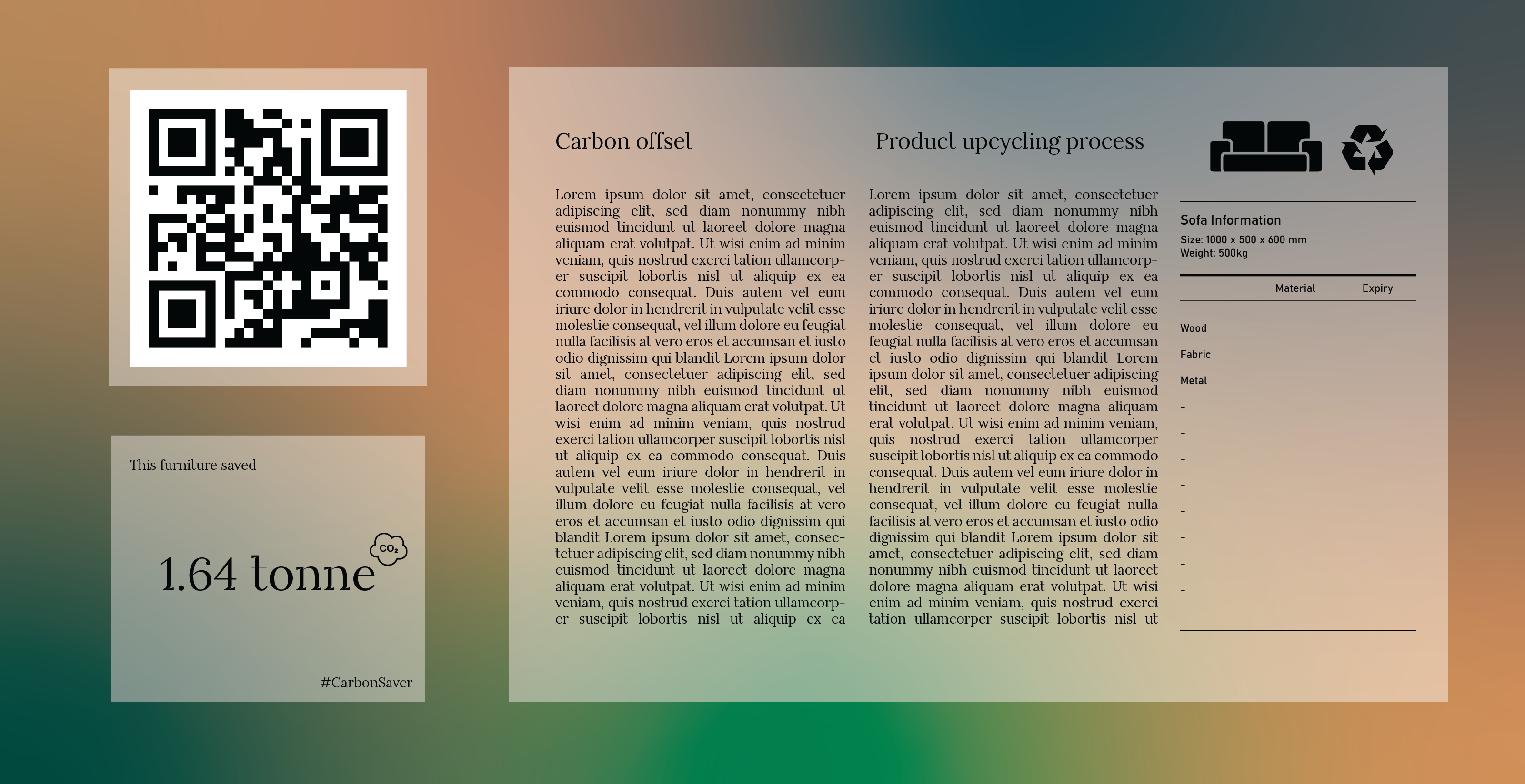

Surapa Phataraprasit’s design (below) combines a nature-inspired colour scheme with key information on how the furniture was up-cycled and how much carbon was saved, with space for company logos and a QR code for more information.

Design for sustainable furniture label – Surapa Phataraprasit. Bartlett Eco Label © 2022 by Surapa Phataraprasit is licensed under CC BY 4.0

Design for sustainable furniture label – Surapa Phataraprasit. Bartlett Eco Label © 2022 by Surapa Phataraprasit is licensed under CC BY 4.0

This update reflects our first steps in this complex area of procurement emissions. However, it also shows the value of collaboration across the faculty. The progress described has been enabled by the contributions of professional services, research and academic staff, of students and of our suppliers. We’re very grateful for the contributions of all of these people and excited about what more we can achieve if we continue to bring together our contrasting and complementary sets of skills and knowledge.

* The research team was led by Negar Taatizadeh and Felix Sagar (both 2022 Masters of Architecture graduates), and consisted of Ismail Mir (MSci Architecture), Hetian Zhang (Engineering & Architectural Design M.Eng), Frista Marchamedya (Masters of Architecture & Historic Urban Environments), Will Scott (Bio-Integrated Design MSc), Gabriele Grassi (Masters of Architecture), Tessa Winkelhake (MA Situated Practice), Eduardo Nuñez Luce (Architectural Design M.Arch) and Melih Kamaoglu, PhD Candidate in Architecture & Digital Theory. The team was supervised by The Bartlett School of Architecture Environmental Design Lecturer Blanche Cameron.

Close

Close