Lifting Equipment Standard

This Standard applies to all lifting equipment used by employees, i.e. staff and postgraduate students, at UCL.

Scope

This Standard applies to all lifting equipment used by employees, i.e. staff and postgraduate students, at UCL. Specifically, it details the arrangements to ensure that such equipment is thoroughly examined/inspected and tested by competent persons at appropriate intervals.

Arrangements for all other aspects of the management and use of lifting equipment, including planning for lifting operations, are detailed in Safety Services guidance (for Departmental equipment) and UCL Estates Standard Operating Procedures (SOPs) for Estates owned equipment.

Legal requirements

The Lifting Operations and Lifting Equipment Regulations 1998 (LOLER) requires UCL to:

- Ensure that equipment used for lifting is:

- Sufficiently strong, stable and suitable for the proposed use – this includes the load and anything attached to it

- Positioned or installed to prevent the risk of injury

- Visibly marked with any appropriate information to be taken into account for its safe use, e.g. safe working loads and accessories e.g. slings, clamps etc, should be similarly marked

- Plan, supervise and carry out lifting operations safely, using competent people

- Ensure that equipment (and any accessories) is thoroughly examined before the first use and at regular intervals thereafter, by a competent person

Definitions

- Lifting Equipment: Any equipment used at work for lifting and lowering loads, including attachments used for anchoring, fixing or supporting it. This includes:

- Equipment such as cranes, fork-lift trucks, lifts, hoists, mobile elevating work platforms and vehicle inspection platform hoists

- Lifting accessories such as chains, slings, eyebolts etc

Lifting Operation: An operation concerned with the lifting or lowering of a load and a “load” includes a person.

Risks associated with lifting equipment

The main hazards are being injured by:

- Moving parts of machinery – for example being drawn in, trapped or crushed

- Dropped or ejected material

- Sharp edges or sharp-pointed parts

- Hot or cold surfaces

- Parts of the equipment which may fail and/or loads may drop

Responsibilities

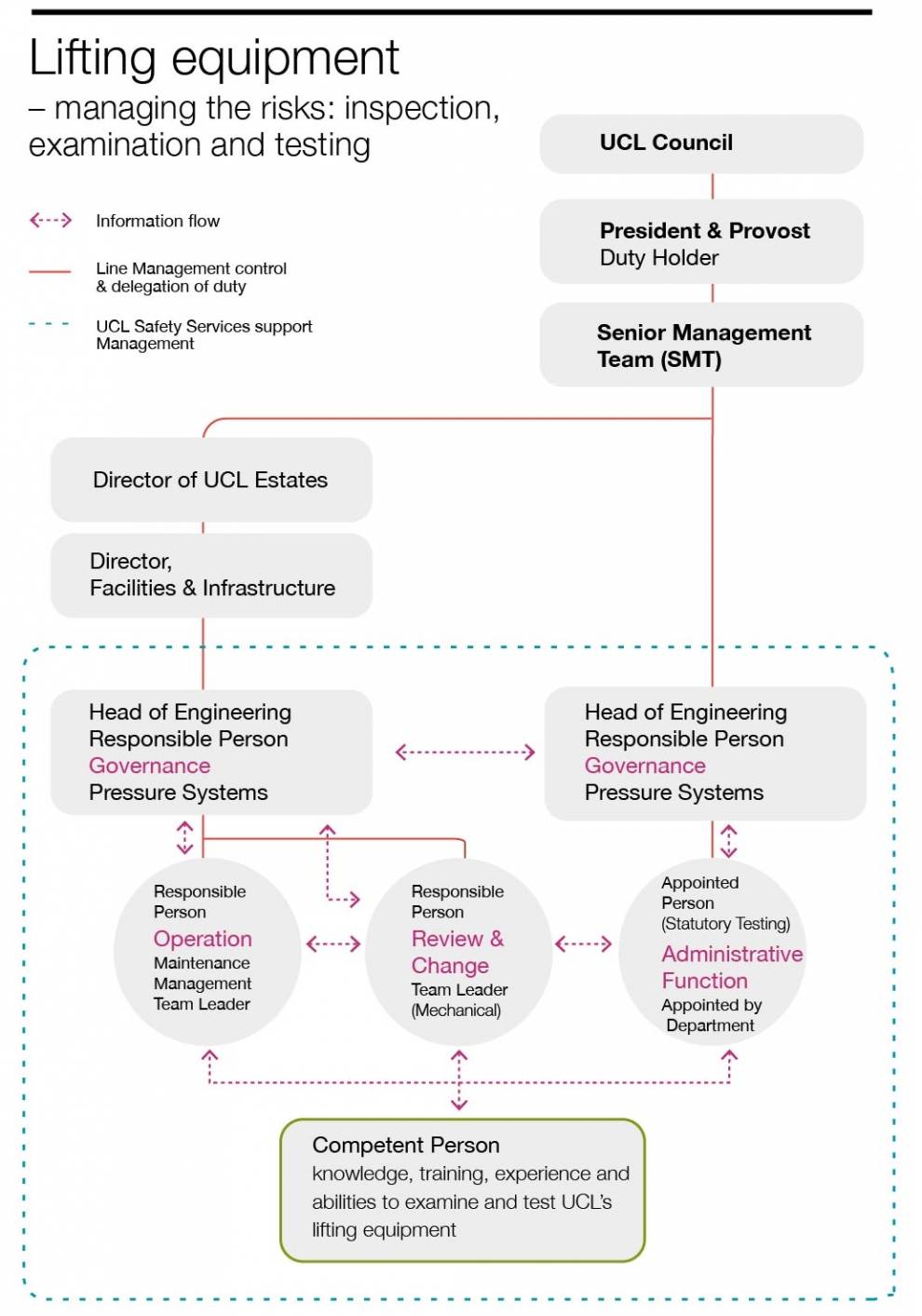

The principal responsibilities for the management of health and safety are stated in the UCL Safety Policy (with line management/delegation of duty shown in the above organogram). Specific responsibilities relating to the management of lifting equipment are stated below.

In all instances, the term ‘Responsible Person’, and the associated duties, applies equally to any nominated deputy formally appointed to act on all occasions when the nominated Responsible Person is unavailable.

- Head of Engineering – Responsible Person – Lifting Equipment Governance

The Head of Engineering has managerial responsibility for the governance of lifting equipment risk compliance and providing supervision for the implementation of the precautions through:

- Managerial responsibility for the UCL Standard and associated SOPs for the management of UCL’s lifting equipment risks

- Appointing, in writing, ‘Responsible Persons’ to be responsible for the day-to-day management of the examination and testing of UCL’s lifting equipment (as well as other relevant duties)

- Ensuring that the Responsible Persons are aware of their roles and responsibilities and that they are competent to carry them out

The full details, expectations and requirements of this role are contained within the UCL Lifting Systems SOP, which is controlled by UCL Engineering, Maintenance and Infrastructure.

- Responsible Person – Lifting Equipment – Operation

The Responsible Person – Lifting Equipment – Operation has been delegated the primary role to act as administrator in the management of lifting equipment in accordance with this UCL Standard and has managerial responsibility for supervising the implementation of this UCL Standard, the SOP, and the management of the lifting equipment under the control of UCL Estates.

- Responsible Person – Lifting Equipment – Review and Change

The Responsible Person – Lifting Equipment – Review and Change has been delegated the managerial responsibility for:

- Reviewing the compliance and performance against this Standard

- Preparing the Estates Standard Operating Procedures for lifting equipment management on behalf of the Head of Engineering, and periodically audit their implementation

- Supervising the implementation of this Standard and the management of any changes, additions to, or replacements of existing installations or equipment, or any new installations of lifting equipment under the control of UCL Estates

- Notification of any changes to holdings of lifting equipment pressure systems at UCL to UCL’s insurers

The full details, expectations and requirements of this role are contained within the UCL Lifting Equipment Standard Operating Procedure.

- UCL Estates (Capital Projects, Project Officers and Maintenance)

UCL Estates (and any consultants they appoint) are responsible for ensuring equipment is designed, installed and maintained in accordance with this UCL Standard, the Standard Operating Procedure and relevant documents listed in the references section of this standard. The Responsible Person – Lifting Equipment -– Review and Change is to approve each stage of any design. No equipment will be accepted unless the Responsible Person – Lifting Equipment – Review and Change has given the final written approval.

- Heads of Departments (other than UCL Estates), Responsible Person – Pressure Systems Governance

Heads of Departments are responsible for identifying, assessing and controlling the risks from lifting equipment used in their department not otherwise managed or owned by UCL Estates. Where such systems exist, the Head of Department must appoint a person(s); the Appointed Person (Statutory Testing) to prepare and maintain a local inventory of specific items and types of equipment (including accessories) to facilitate testing and examination by UCL’s competent person. Details of the Appointed Person(s) must be kept in the Responsible Persons Register on riskNET.

- Appointed Person – Statutory Testing

The Appointed Person will maintain a list of lifting equipment and associated accessories used by their department. This information must be notified to the Responsible Person – Lifting Equipment – Review and Change as required/directed. Any changes to the list i.e. new equipment purchased or equipment out of use/disposed of, must be notified to the Responsible Person as soon as possible. New equipment should be notified in advance of installation so that an inspection can be carried out before the first use of the equipment.

The Appointed Person should liaise with relevant departmental staff to facilitate access, when required, to lifting equipment for the purposes of testing and examination by UCL’s competent person.

- Competent Person

The competent person will be appointed by UCL to:

- Where appropriate, inspect lifting equipment before first use

- Carry out thorough examination and testing of lifting equipment at intervals set out in relevant legislation or else in accordance with a scheme prepared at the first inspection

- Issue reports to UCL following preparation of the initial inspection and subsequent examination and testing of lifting equipment

Records

The Responsible Person – Lifting Equipment – Operation will maintain an inventory of all UCL lifting equipment and keep records to assist the competent person with their inspections. The following records will be kept:

- Any documents provided by the designer/manufacturer/supplier relating to the lifting equipment

- The EC Declaration of Conformity

- The most recent examination report produced by the competent person

- Any agreement or notification relating to the postponement of the most recent examination scheme

- All other reports which contain information relevant to the assessment of matters of safety

Monitoring and review

This Standard shall be reviewed at least annually to ensure it remains up-to-date.

References

- Safe use of lifting equipment: Lifting operations and lifting equipment Regulations 1998 Approved Code of Practice and guidance L113 HSE Books (HSE)

- Lifting operations and lifting equipment Regulations 1998 SI 20307/1988 (Gov.uk)

Last updated: Thursday, September 13, 2018

Close

Close