The science behind the research

- To develop and manufacture anti-icing coatings based on a) surface textured/treated coatings and b) nanocomposite coating concepts in order to obtain the desired anti-icing properties;

- To establish the relationships between the surface topography/chemical compositions of anti-icing coatings and the thermal/mechanical interaction of coatings with ice.

Ongoing research

Adherent and uniform nanocomposite coatings (circa. ~2µm thick) have been successfully fabricated onto Al-alloy foils. Figure 1 shows the photos of uncoated plannar Al-alloy foil, crack-free and uniformly coated plannar Al-alloy foil (b) and coated curved Al-alloy foil (b) and the SEM image of the deposited nanocomposite coating containing carbon nanotubes.

| Fig.1 Photos of (a) uncoated Al-alloy 608 foil, (b) coated Al-alloy foil with novel nanocomposite coating, and (c) curved Al-alloy foil coated with nanocomposite coating as well as the SEM image of the deposited nanocomposite coating. |

|

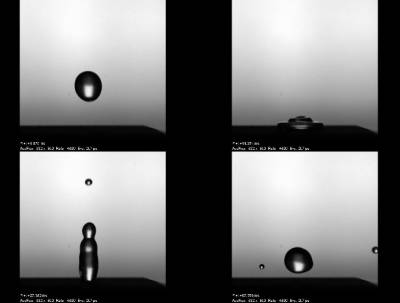

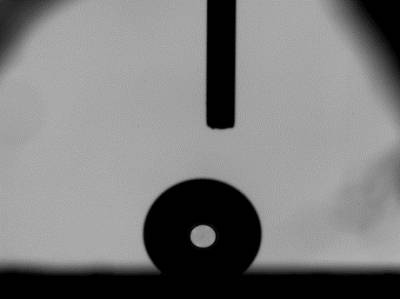

The fabricated nanocomposite coatings were superhydrophobic. Figure 2 shows images captured with high speed camera of water drop bouncing off superhydrophobic surface and Figure 3 shows pictures of water drop on superhydrophobic surface (>150oC). The novel nanocomposite coatings were electrically conducting with sheet resistance below 300 Ω/□.

The coating deposited on the as-received Al-alloy foil was easily removed from the substrate. Modification of the substrate improved the scratch resistance, with coating deposited on physically modified substrate with scratch resistance up to 8 mN, and chemically modified substrate with scratch resistance up to 30 mN.

The optimisation of the nanocomposite formulation further improved scratch resistance up to 250 mN in the current test, no failure observed at 50 mN.

| Fig.2 (left-hand-side) Images captured with high-speed camera of water drop bouncing off superhydrophobic nanocomposite coating surface; and (right-hand-side) Superhydrophobic surface | |

|  |

Through the modification of the structure and chemical treatment of the nanocomposite coatings, it is possible to fabricate adherent and robust nanocomposite coatings with superhydrophobicity and low sheet resistance, promising to be applied for anti-icing/de-icing applications.

The research carried out on the development of anti-icing/de-icing nanocomposite coatings is well underway towards the development of a suitable solution.

Potential applications

Applications of the anti-icing/de-icing coatings include aviation, naval and automotive industries, as well as Arctic oil and gas exploration.

Recent publications

- Sandhu, A., Walker, O., Nistal, A., Choy, K. L., & Clancy, A. (2019). Perfluoroalkane wax infused gels for effective, regenerating, anti-icing surfaces. Chemical Communications, 55, 3215-.3218 doi:10.1039/C8CC09818B

- Chen, T., Jin, J., Qi, Y., Tian, W., Cong, Q., & Choy, K. L. (2019). Disturbing stability of interface by adopting phase-change temperature gradient to reduce ice adhesion strength. Cold Regions Science and Technology, 158, 69-75. doi:10.1016/j.coldregions.2018.11.010

- Chen, T., Cong, Q., Jin, J., & Choy, K. L. (2018). Experimental study on frost-formation characteristics on cold surface of arched copper sample. Plos One, 13 (12), ARTN e0208721. doi:10.1371/journal.pone.0208721

- Chen, T., Cong, Q., Qi, Y., Jin, J., & Choy, K. L. (2018). Hydrophobic durability characteristics of butterfly wing surface after freezing cycles towards the design of nature inspired antiicing surfaces. Plos One, 13 (1), ARTN e0188775. doi:10.1371/journal.pone.0188775

- Chen, T., Cong, Q., Sun, C., Jin, J., & Choy, K. L. (2018). Influence of substrate initial temperature on adhesion strength of ice on aluminum alloy. Cold Regions Science and Technology, 148, 142-147. doi:10.1016/j.coldregions.2018.01.017

- Janju, Z. A., Turnbull, B., Choy, K. L., Pandis, C., Liu, J., Hou, X., & Choi, K. S. (2017). Performance and durability tests of smart icephobic coatings to reduce ice adhesion. Applied Surface Science, 407, 555-564. doi:10.1016/j.apsusc.2017.02.206

Patents

- Patent submitted to UK Intellectual Property Office (Patent Application Number GB1512618.8). KL Choy, J Restivo, Novel anti-icing and/or de-icing coating and technologies

Close

Close