Biocatalysts Ltd partner with UCL to tap into revolutionary bioprocessing technology

Global biotechnology company Biocatalysts Ltd is accessing cutting-edge bioprocessing technology developed at UCL to gain market advantage.

1 March 2022

Biocatalysts manufactures off-the-shelf and speciality enzymes for top food, flavour and pharmaceutical companies. Their products are a vital part of the production process for their customers, who benefit in particular from Biocatalysts’ ability to develop customised enzymes rapidly and at low cost.

To streamline their processing capabilities further, the company embarked on a Knowledge Transfer Partnership (KTP) project in 2018 with UCL’s Department of Biochemical Engineering.

The project has given Biocatalysts access to revolutionary new bioprocessing technology, developed by UCL researchers, which significantly accelerates the development of their enzymes.

Opening the door to world-leading technology

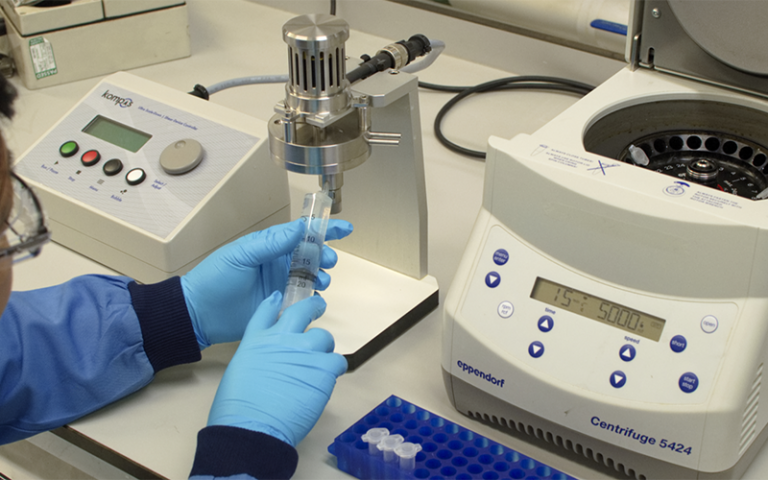

“The Ultra Scale-Down (USD) kompAs™ device we’ve developed at UCL allows us to mimic the forces that enzymes are exposed to in large-scale operations, using just millilitres of materials. This has many benefits for a company such as Biocatalysts as it allows them to test and evolve enzyme processes in a lab environment, removing the need for expensive, large-scale testing,” explains Dr Andrea Rayat, Associate Professor in Bioseparations at UCL. Andrea was the academic advisor on the KTP, working alongside Professor Michael Hoare.

During the two year-project, Biocatalysts and UCL experts collaborated closely to integrate this new technology into Biocatalysts' business. As well as access to the tool itself, Biocatalysts benefitted from UCL’s advanced biochemical engineering expertise, including training, process design, rapid prototyping and 3D printing.

“When we started the KTP project with UCL, we were keen to investigate and ideally implement new technologies that could benefit our development and manufacturing capabilities,” explains Craig Galeozzie, Biocatalysts’ Director of Operations.

“The project proved extremely successful and had an immediate influence on our internal process scale-up methodologies. Furthermore, the process efficiency improvements and commercial benefits aligned to the project are now fully integrated within our manufacturing procedures. It’s been a very productive and rewarding project for all involved, once again proving how true academic research can influence and ultimately benefit modern industry.”

Cementing Biocatalysts’ position as a world-leading specialist

Since working on the KTP, Biocatalysts have embedded UCL biochemical engineering expertise into their practices. “As well as significantly streamlining the way we work, we’ve been able to use this new technology to develop new enzymes that result in milder, less energy-intensive manufacturing processes for our customers. We’re now looking to double our manufacturing capacity again, as a result of the efficiencies achieved using this new tool,” explains KTP Associate Davy Rowan.

The significant progress achieved on the KTP has led to UCL and Biocatalysts being recognised in the IChemE Global Awards 2020. The team were winners in the Food & Drink Category and finalists in the Biochemical Engineering Category. They’ve also been selected as finalists in the Engineering Excellence category of the KTP Awards, Best of the Best 2021.

Building on a strong relationship

As for what’s next, Biocatalysts are keen to keep their culture of continuous improvement going. They’ve recruited their KTP Associate, who acted as the interface between the company and university, into a new Process Improvement Specialist role.

“Working with Biocatalysts beyond the KTP means we can keep the momentum going in terms of knowledge transfer, and implement more cutting-edge downstream processing techniques from UCL experts,” adds Davy.

Biocatalysts and UCL are also working together in other ways, with Biocatalysts delivering industry seminars, supporting UCL’s taught programmes and working on joint publications and events. They’re now exploring the possibility of future KTPs to continue their mutually beneficial relationship.

“Working with Biocatalysts has been highly advantageous for us as a research team,” adds UCL’s Dr Rayat. “Most importantly, the KTP has helped us verify that our Ultra Scale-Down technology can be incorporated by industry to great positive effect. We’ve seen its potential and the hugely transformative effect it can have on a company first hand.”

The KTP between UCL and Biocatalysts has been supported by UCL Innovation & Enterprise, who helped with applying for funding, setting up the partnership, and the administrative aspects.

Watch a video about this KTP

In this video, Professor Mike Hoare talks about the KTP between Biocatalysts and UCL and the ultra scale-down technologies at the centre of this collaboration.

Knowledge Transfer Partnerships

Knowledge Transfer Partnerships (KTPs) aim to help businesses improve their competitiveness and productivity through better use of the knowledge, technology and skills held within the UK knowledge base. This KTP project received financial support from UKRI through Innovate UK.

Links

Find out more about:

- Biocatalysts

- UCL Department of Biochemical Engineering

- KTP Project wins IChemE Global Award 2020

- KTP awards: Best of the Best Awards 2021

- For businesses - Working on a Knowledge Transfer Partnerships (KTP) with UCL

- For UCL staff - Transform businesses through a Knowledge Transfer Partnership (KTP)

- Search for a KTP Associate role

- Innovate UK

- KTN (Knowledge Transfer Network)

Photo © Biocatalysts Ltd

Close

Close