i) Efficient encapsulation: TIPS microspheres offer a platform for incorporating a range of therapeutic compounds with high encapsulation efficiency (including those that are prone to leaching out during washing phases required with other microsphere technologies), offering scope for controlled localized drug release.

We have demonstrated the processing technique provides higher encapsulation efficiencies of active pharmaceutical ingredients compared with traditional microsphere processing techniques and retention of their biological activity.

It is possible to load TIPS microspheres with drug post-manufacture facilitating a rapid pathway to clinical evaluation.

ii) Efficient manufacturing: The TIPS manufacturing process is rapid and highly efficient. We have established scale-up manufacture of clinically qualified TIPS microspheres in-house and with a Contract Manufacturing Organization (Polysciences Inc.).

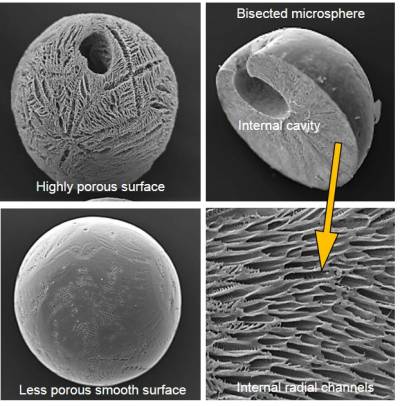

iii) Tuneable features: The manufacturing process is amenable to fine adjustment, enabling control of features such as size and porosity, providing bespoke microspheres that match end user needs.

iv) Conformable scaffold: When delivered into tissues as a scaffold device the microspheres provide an open porous structure ideal for guiding tissue growth. When delivered as a paste the microspheres are able to conform to irregular shaped tissue cavities.

v) Unique structure: The unique structure of TIPS microspheres consists of radial channels and a porated skin. In vivo studies has proven this structure facilitates rapid (<1 week) integration with host tissue.

vi) Biodegradable: TIPS microspheres can be made from a variety of degradable or non-degradable materials.

Close

Close