Challenge-led research addressing biomanufacturing and bioprocessing issues to successfully translate and scale-up advanced-therapy medicinal products including cell, gene and regenerative therapies

Whole Bioprocess Approach for Cell and Gene Therapy Development

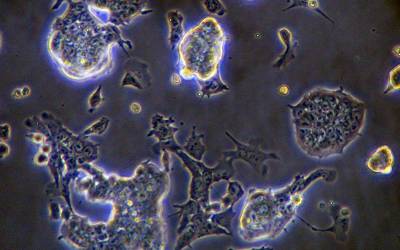

To address this, the research focus is on the development of standardised, scalable and robust manufacturing processes for the consistent manufacture of clinical-grade ATMPs. We adopt a ‘Whole Bioprocess’ perspective which encompasses all key processing steps required for the production of CGTs, including the cell isolation and processing, cell expansion and manufacture, characterisation and control, downstream processing and preservation and delivery of the final cell product. Moreover, this includes the development and optimisation of gene-editing and gene delivery methods, including viral vector and non-viral delivery methods.

Consistency-driven Development of Cell and Gene Therapies

A core aspect of the research is to establish a consistency-driven development approach to address the inherent biological and process variation of CGTs, and ultimately improve both product and process understanding. This is achieved by employing Quality by Design (QbD) tools such as risk assessments, processing mapping and factorial Design of Experiments (DoE) to improve final product yield and quality. Using such tools, we can establish, investigate and understand the impact of key culture parameters on the production of the CGTs. This is further enhanced through the use of advanced high-throughput, small-scale cell culture platforms, computational modelling for bioprocess design and scale-up, and automated manufacturing technologies.

Key Research Challenges for Cell and Gene Therapy Development

- Development of automated, scaled and consistent CGT production systems and processes

- Translation to commercial manufacture and clinical use, and enabling current good manufacturing practice (cGMP) compliant manufacturing

- Establishing measurement systems for process control and quality release

- Development of decisional tools, COGs and business models for effective translation

- Identifying and minimising variability associated with input material for CGT manufacture

- Development of suitable manufacturing scale-down models to de-risk process scale-up

- Addressing the supply chain and logistic challenges associated with CGT delivery

- Development and optimisation of gene-editing and gene-delivery methods for ATMP production.

Close

Close