UCL Qatar (2010-2020)

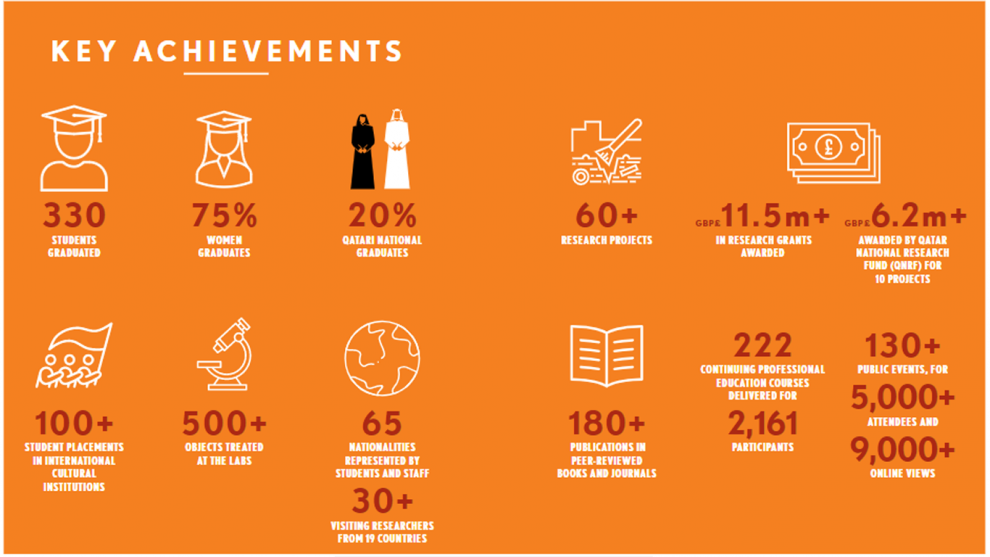

UCL Qatar delivered 230 professional education courses, attended by more than 2,500 participants. Aiming to support both emerging and established heritage professionals, many of the short courses had a regional and local focus.

UCL Qatar received over £11m of funding for research for around 100 projects spanning from Myanmar to Spain, with a special focus on the Arab and Islamic World, involving UCL Qatar academics, students and international experts.

The nine world-class conservation and material sciences labs handled and treated over 500 historical objects and hosted more than 30 visiting researchers from 19 countries.

The Library at UCL Qatar was a major source of cultural heritage materials for students, staff and the wider community, with a collection of more than 16,000 volumes of printed books and journals, as well as electronic publications.

Community engagement was one of UCL Qatar’s strategic objectives, with the university’s public engagement programmes taking archaeology, conservation, libraries and museums to communities across Qatar through over 130 public events, which were attended by more than 5,000 attendees and collected over 9,000 online views.

UCL Qatar was also home to a diverse community of world-class academics and an accomplished, international team of non-academic staff. Many moved to Qatar to pursue a genuine interest in the nation’s culture and heritage, and play their part in its development and preservation.

Partners and stakeholders

- Qatar Foundation

A private, non-profit organisation, the Qatar Foundation supports and operates programmes in three core mission areas: education, science and research and community development. Through its work, it strives to lead the social and economic development of Qatar. - Qatar Museums

Along with overseeing an array of museums and galleries, Qatar Museums promotes art, heritage and creativity in and around Qatar by taking the cultural experience beyond the four walls of a museum into the world at large. - Qatar National Library

- Qatar Tourism Authority

- Hamad bin Khalifa University

- British Council Qatar

- Museum Big Data Conferences

- The Origins of Doha and Qatar Project

- Qatar-Sudan Archaeological Project

Close

Close