Supporting commercial nanotechnology

12 December 2014

A collaboration between UCL and nanotechnology company Zyvex Labs has helped the company improve its atomically precise manufacturing processes and develop a new commercial patterning system, which is due to be launched in 2015. Zyvex has also used the research as it expands into manufacturing techniques for quantum computing devices.

Atomically precise manufacturing (APM) is the production of structures with the precision of single atoms. It underpins new technologies, from simple quantum dots to devices for the harvesting and storage of energy.

Zyvex, based in Texas, develops commercial products in the nanomaterials and nanomanipulation areas. The company has already developed a nanoprobe system that is in wide use throughout the semiconductor industry. Its collaboration with UCL, which began in 2007, has helped it to develop a new system, which is due to be launched in 2015.

Zyvex has developed techniques to create nanoscale patterns with atomic precision and then grow new material on top of the patterns. This is done by coating silicon with a layer of hydrogen atoms and selectively removing some hydrogen to create a base pattern. UCL's research modelling the interaction of hydrogen atoms with silicon surfaces provides important limits for Zyvex to use to improve their techniques, such as identifying the temperatures at which the hydrogen atoms start to move on the silicon, which is vital for controlling and managing the growth processes. The growth of new silicon requires elevated temperatures, and so the atomically precise control would be impossible without knowing the temperatures at which the hydrogen mask would degrade.

Professor David Bowler's modelling of the fundamental physics of Si surfaces is enabling Zyvex Labs efforts to develop atomically precise manufacturing technology for quantum computing devices and other advanced nanotechnology. - John N. Randall, President Zyvex Labs.

The company is developing products based on this patterning: control electronics for scanning tunnelling microscopes (STMs), to allow patterning; and turn-key systems to be added to STMs, to give a complete patterning and growth system. Both of these systems will allow other companies to produce patterns and grow new materials within the patterns.

The UCL research has also helped a consortium led by Zyvex Labs to obtain over $14 million in funding for research contracts from the US Defense Advanced Research Projects Agency and the State of Texas, awarded to enable the accelerated commercialisation and market adoption of atomically precise devices and manufacturing approaches.

Since 2013 Zyvex Labs has also been using the UCL research as it expands into a new area - manufacturing techniques for quantum computing devices. In 2013 Zyvex Labs received a multi-million dollar contract from the Army Research Office to further develop atomically precise patterning tools and to disseminate these tools to key quantum computing device researchers.

Zyvex Lab's ability to pattern Si (100) surfaces depends on the detailed understanding of the physics of the Si surface. According to John Randall, President of Zyvex Labs, "David Bowler at UCL is the leading theorist exploring this surface and his work has been indispensable in developing our technology."

Related links

Image

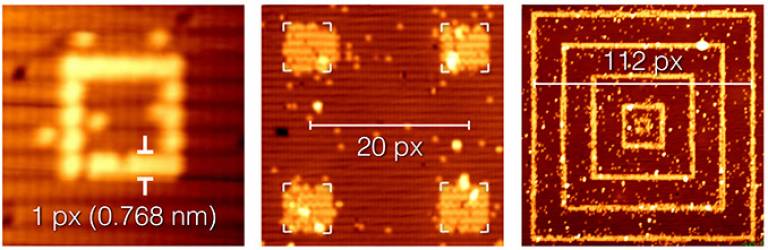

- The individual dots are less than 1nm across (one billionth of a metre). The image resolution is about 30,000,000 dots per inch (DPI). Courtesy of Zyvex Labs.

Close

Close