Power electronics

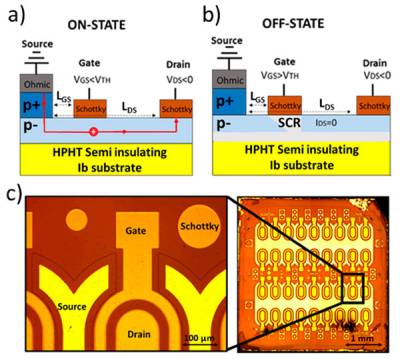

The increased use of distributed energy generation facilities calls for ever more energy efficient power switches and inverters. It is widely recognised that the real step-improvement in Power Electronics can be obtained by employing devices based on wide bandgap semiconductor materials. Wide bandgap semiconductor materials have superior electrical characteristics for power devices when compared to silicon. Power electronic devices based on wide bandgap semiconductor materials will result in substantial improvements in the performance of power electronics systems in terms of higher blocking voltages, improved efficiency and reliability, as well as reduced thermal requirements, leading to realisation of more efficient green electronic systems. Among wide bandgap semiconductors, diamond is considered to be the ultimate semiconductor for applications in high power electronics due to its exceptional properties. Its dielectric breakdown strength is 3 times higher than in SiC and more than 30 times better than in Si. In addition, the carrier mobility is very high for both carrier types and the thermal conductivity is unsurpassed. This work is part of the cubeD postdoctoral research project funded by EPSRC and in collaboration with the University of Cambridge, Neel Institute, DiamFab and Camutronics.

Sensing in extreme environments

Conventional electronic and electrochemical sensor technologies are typically not able to withstand the challenging environments that increasingly need to be monitored for environmental damage. These challenges can be overcome by using diamond-based sensors to keep track of the conditions in the harshest of environments.

Electrochemical testing provides an accurate and precise analysis of a sample, but lacks accessibility and the ability to perform real-time, in-situ measurements. A multi purpose, robust and portable measurement suite can be produced by fabricating a solid state electrochemical cell on a single diamond substrate, allowing for real-time electrochemical analysis in any conditions.

Raman spectroscopy is an excellent technique for chemical identification in, for example, marine environments or those that are geologically remote, as it is based on optical detection, but alone it is insufficiently sensitive for the necessary trace-level sensing. Surface-enhanced Raman Spectroscopy (SERS) on the other hand can be up to one-billion times more sensitive than a standard Raman measurement. Unfortunately, SERS measurements are restricted to the laboratory setting due to the fragile nature of these plasmonic SERS substrates. By exploiting the extremely robust nature of diamond, however, reliable and reusable SERS substrates have been fabricated and tested. Both the incorporation of metallic nanoparticles within a diamond film and the use of nanostructured plasmonic diamond surfaces are being explored here at UCL to enable the first robust SERS technology to developed for detection of a range of species within extreme onshore and off-shore environments.

Radiation Detectors

Global temperatures have been increasing since the early 1900s due to greenhouse gas emissions produced from burning fossil fuels. Alternative greener energy sources are required to reduce emissions and supply the ever-increasing demand for electricity. Nuclear fission and nuclear fusion are among many cleaner energy solutions, that show promise for replacing fossil fuels. To safely operate nuclear power plants radiation detection is required. In these environments it is important to be able to measure radiation present in the reactors and in radioactive waste stores. Radiation detectors in these environments are exposed to large doses of high energy beta, alpha, gamma and neutron particles. Hence robust detectors are needed with high resolution, sensitivity, and low noise.

Diamond has already demonstrated excellent potential in this field, commercial diamond detectors are already available that exhibit 100% charge collection efficiency, high resolution and sensitivity. Furthermore their robustness has also been investigated with diamond detectors that can maintain stable device characteristics after exposure to extreme conditions, including neutron fluences >1014cm-2 . Degradation of detectors however is still a problem in extreme environments and DEG is striving to overcome this with the incorporation of embedded graphitic like electrodes, in collaboration with the University of Oxford. This work is part of the BoltSens postdoctoral research project funded by BAE systems.

Radiation-hardened systems

As a high band-gap material, diamond is inherently radiation-hard, able to withstand bombardment of high-energy particles while maintaining both its impressive physical and electronic properties. By employing this material, the electronic systems in high-radiation environments, such as nuclear power facilities and nuclear accident clean-up, can be vastly improved, both in function and reliability. As the realisation of commercial fusion energy production approaches, efficient and reliable rad-hard electronics become increasingly necessary, with diamond at the forefront of these technologies.

Close

Close