Sruthi Venkatesh

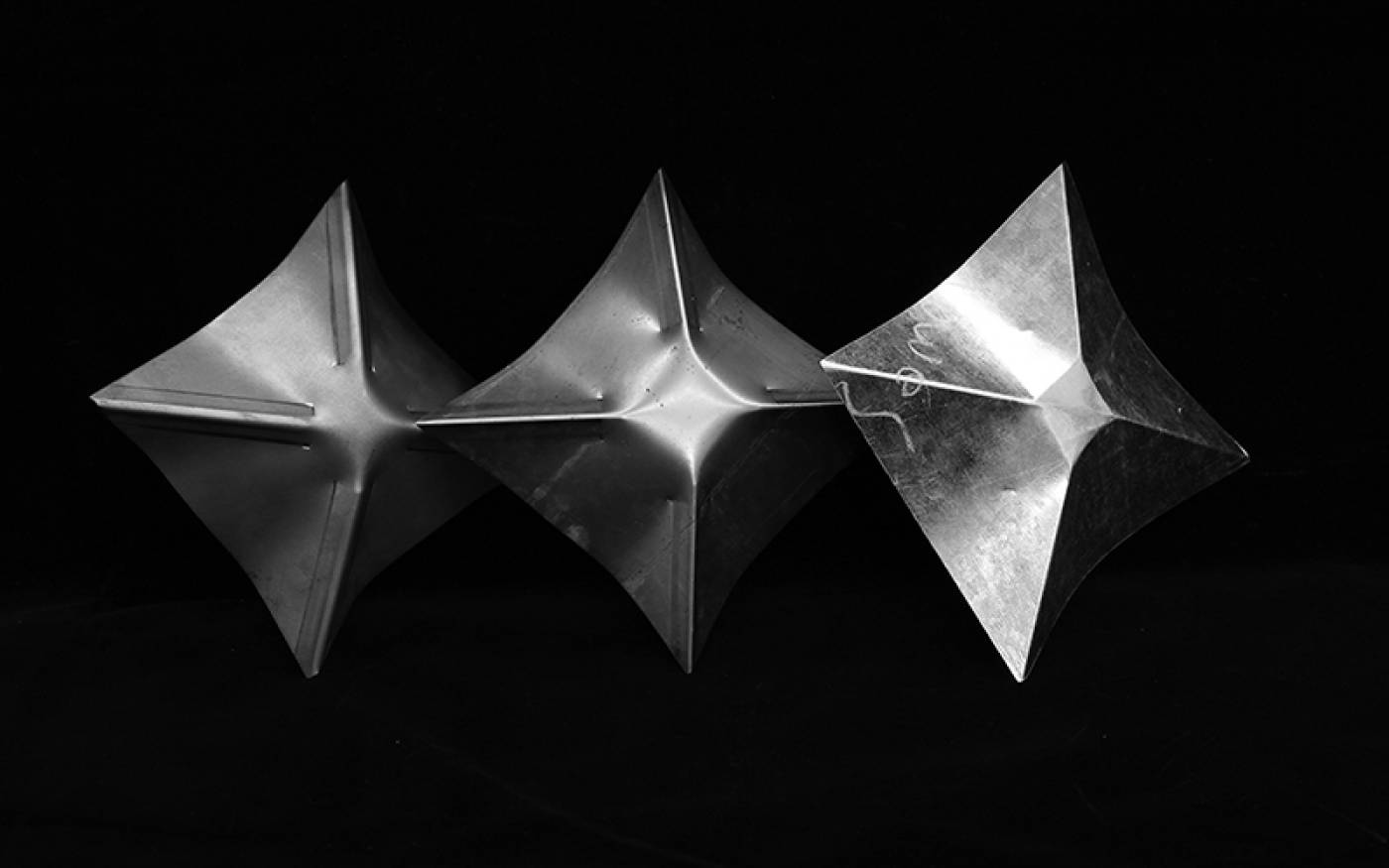

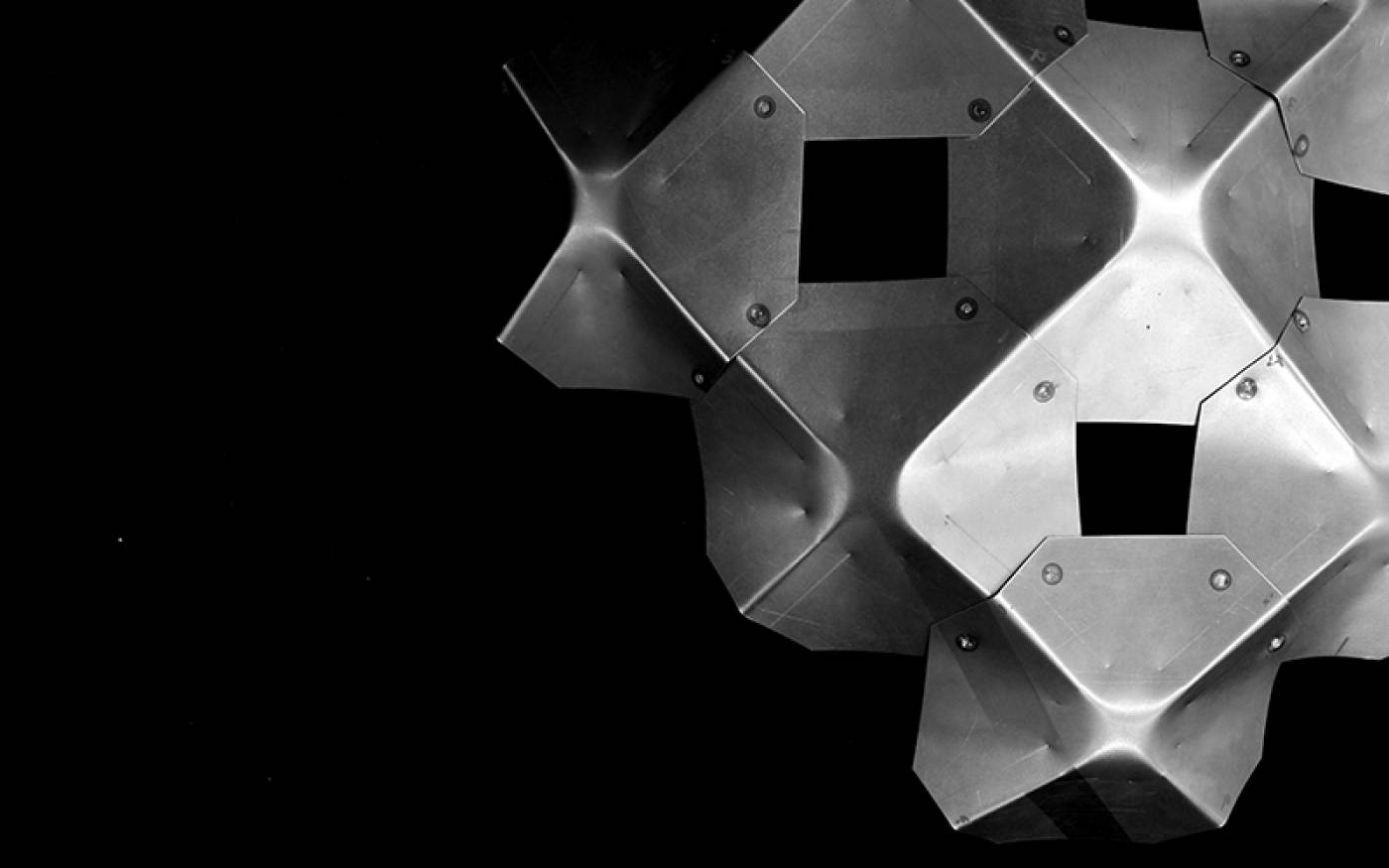

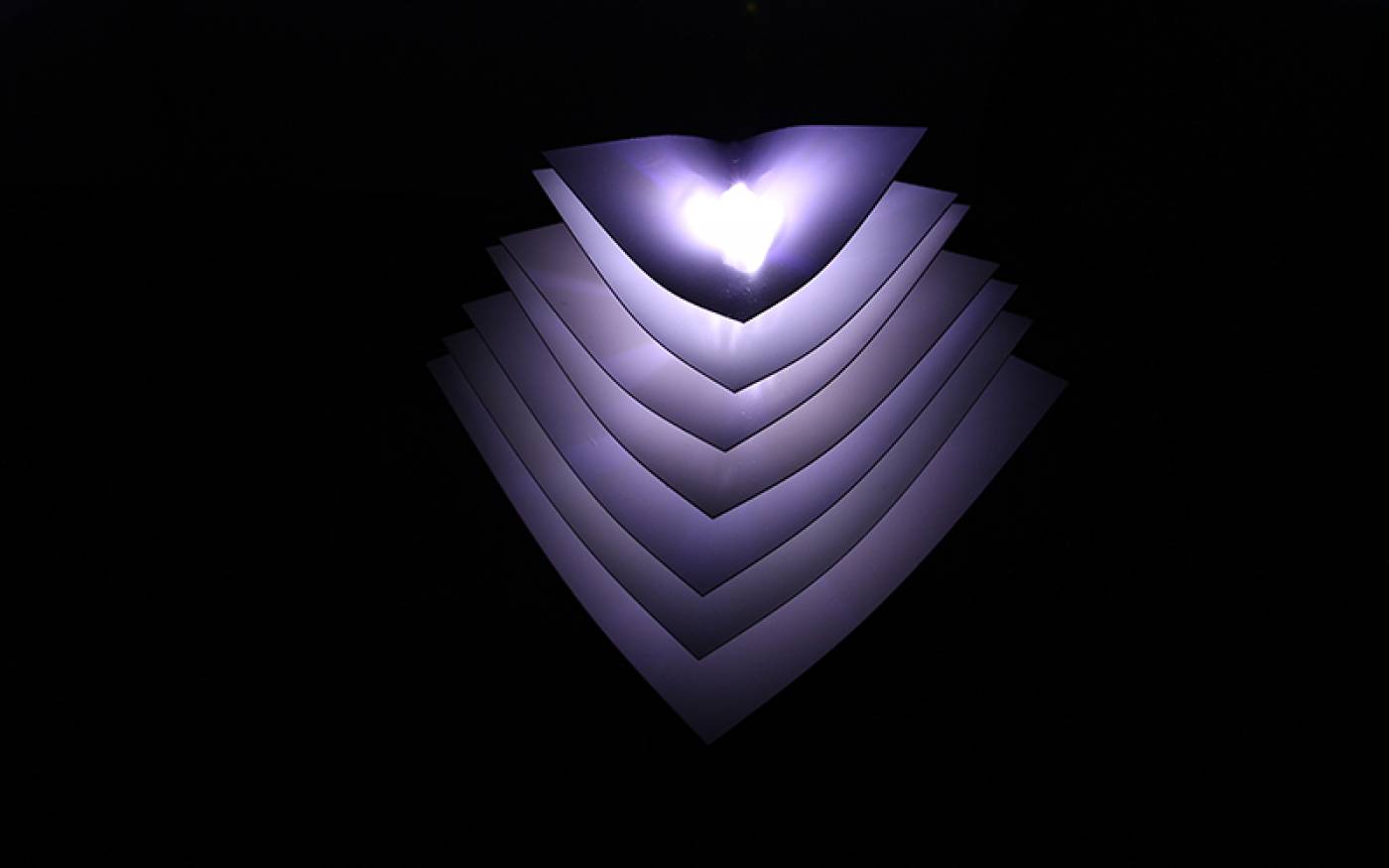

Press-Brake Permutations explores the possibility of an economic method for forming sheet material from simple base geometries such as regular and irregular four-sided shapes. Since these shapes can be accurately and repeatedly cut using low-cost and widely available guillotines it avoids the expense and comparatively inaccessibility of processes such as CNC, waterjet and plasma-torch cutting.

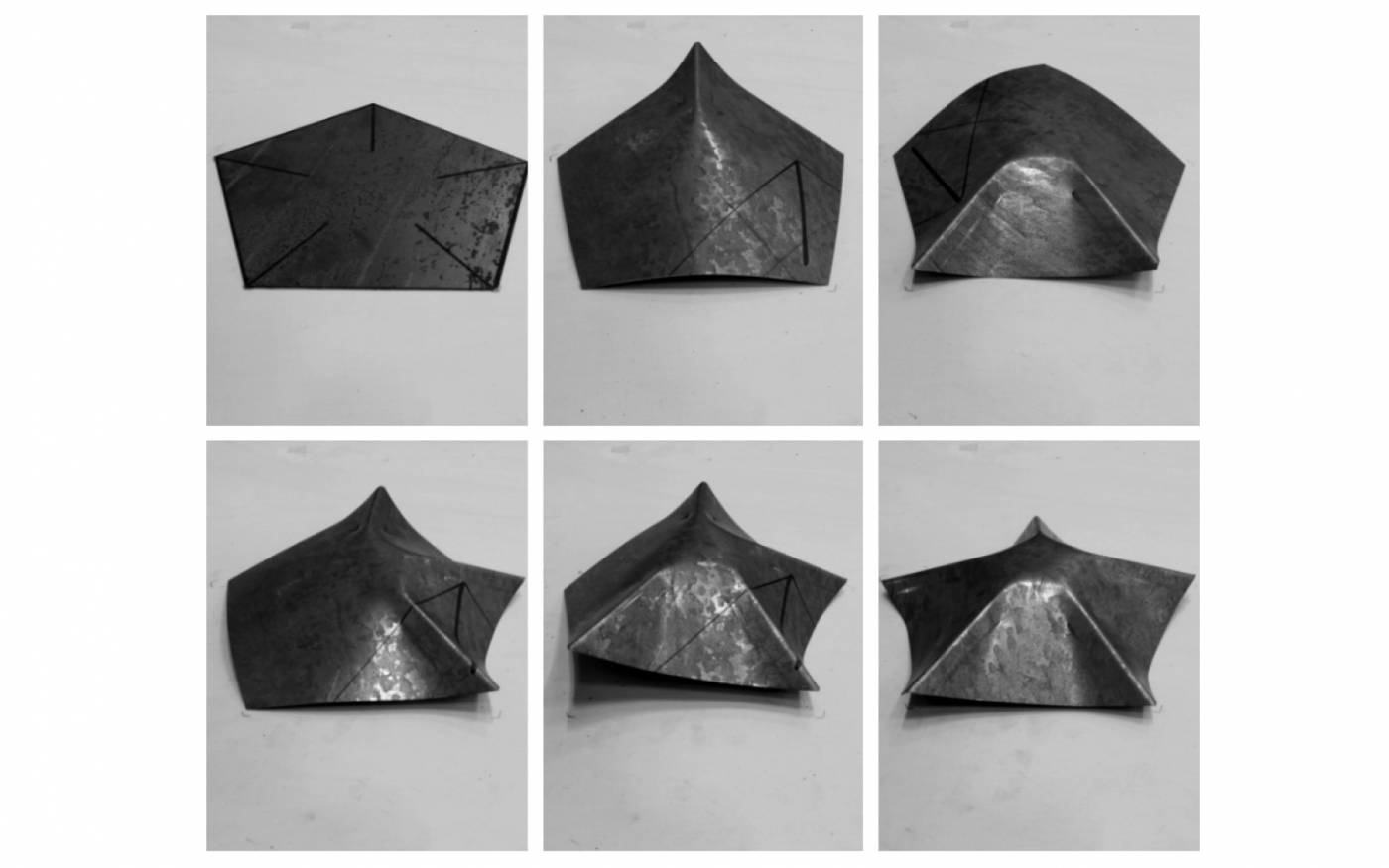

Using only a partial section of the die length on a press-brakes, metal sheets can be pinched along a diagonal to form a range of geometries. This simple and flexible method was explored in contrast to the costly and comparative complexity of forming using a dedicated and die and punch unique to each desired shape.

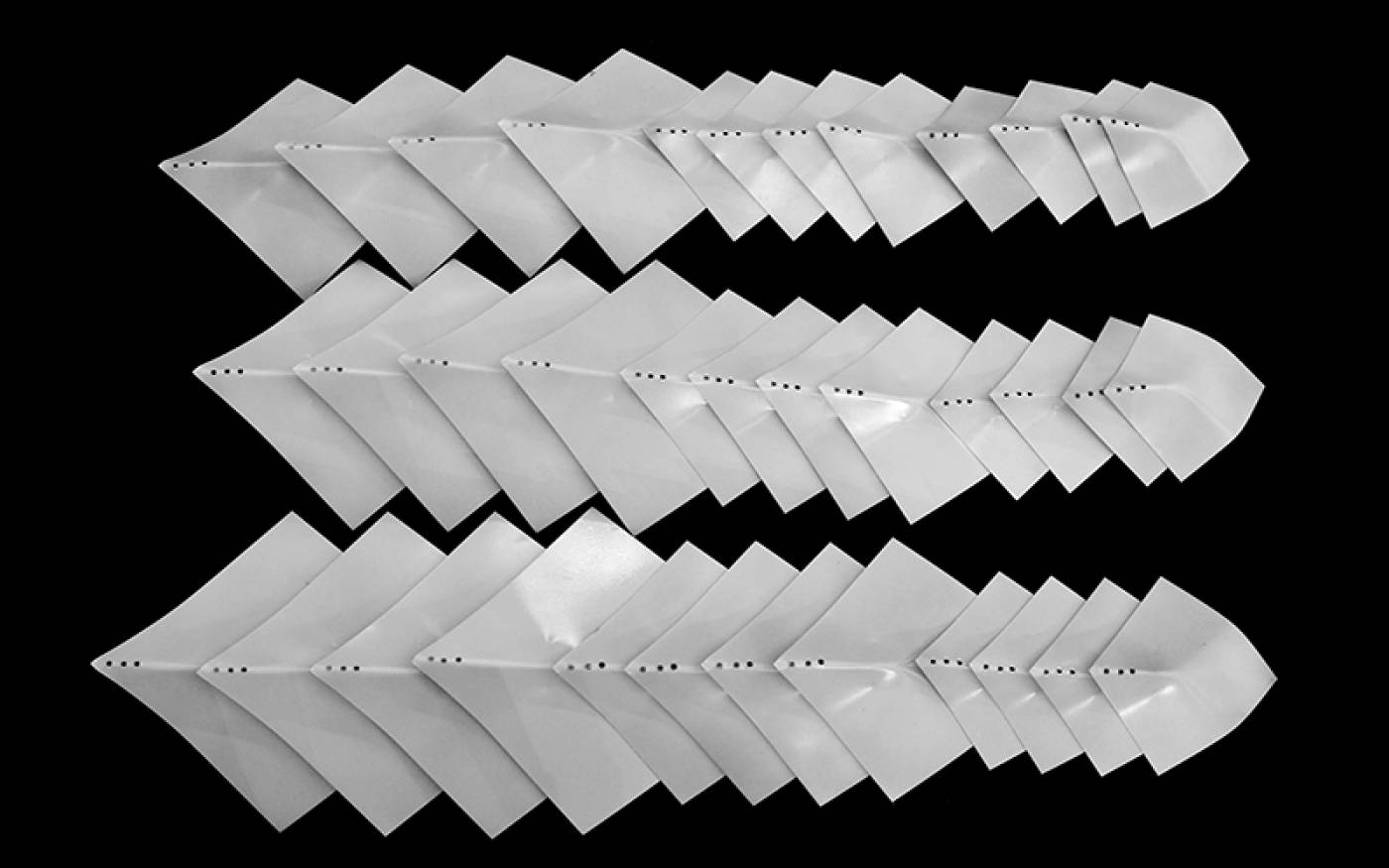

Given that there are 35 dominant factors in die and punch forming compared with just five dominant factors in press-brake forming, press-brake permutations followed a thorough and systematic investigation of the parameters’ values, including fold angle, fold length and die size.

In the process, this project developed a range of customised 3D printed reusable jigs for positioning and alignment of sheet parts to improve the accuracy and repeatability of the forming process. The range of sheet sizes investigated ranged up to approximate 350mm square, however the process can be scaled up to 1500mm square.

Close

Close