Syazwan Bin Mohamed Hanif

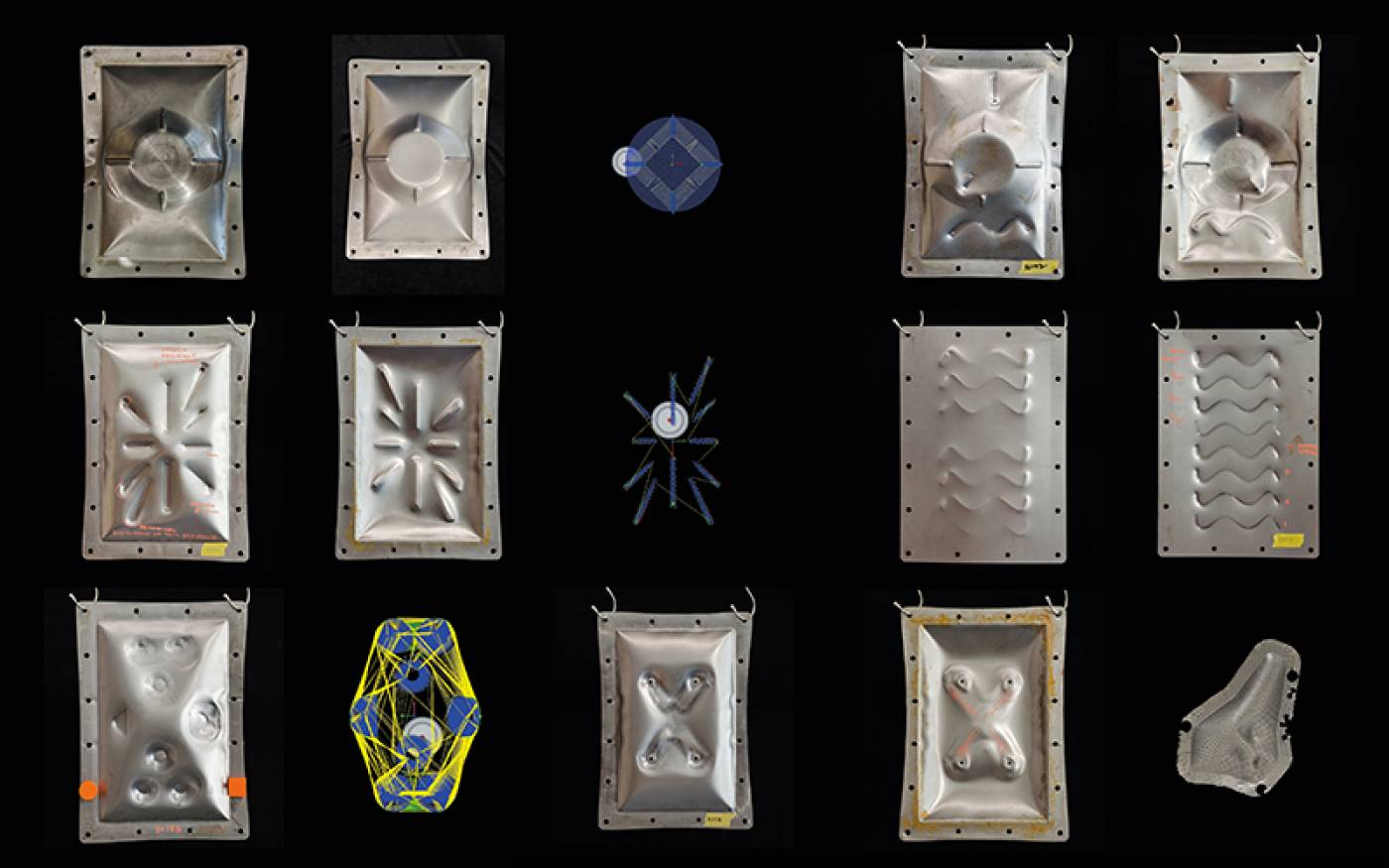

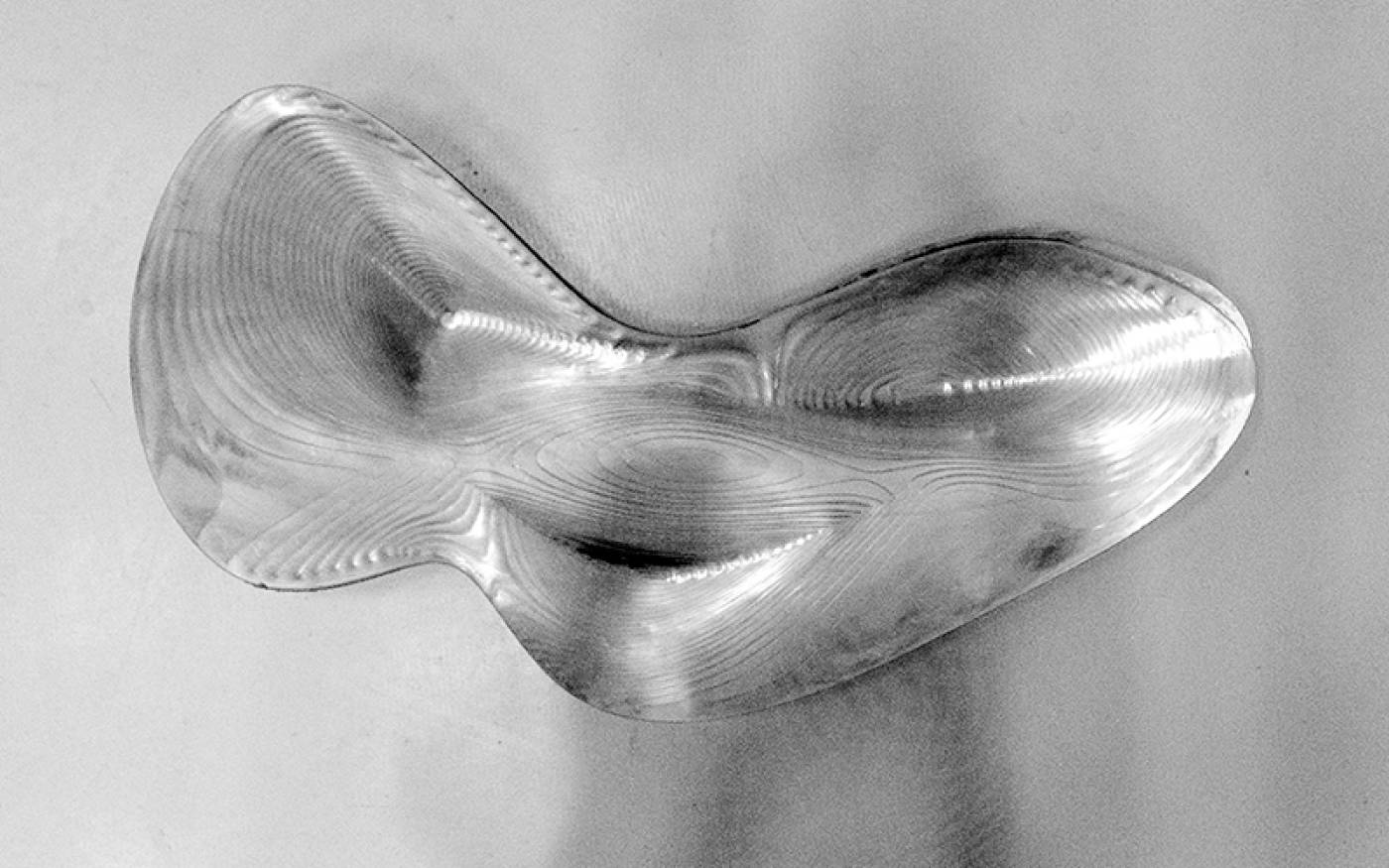

This project explores the forming possibilities using an Incremental Sheet Forming (ISF) process to create a closed volume composed of two irregular surfaces, joined along a common outline that forms its edge, sealed by brazing.

This free-form process is highly flexible in responding to constraints established during prototyping as it does not require the costly and time-consuming process associated with producing a die and punch pair that would have been unique and inflexible to each form. Instead, a multitude of forms are possible with ISF as it requires only a suitable workpiece holding of the size required. The free-form surface geometries have been informed by the constraints inherent in the material type and the ISF process itself, including parameters for step-over distance, tool diameter, tool rpm and feed speed for a given material thickness.

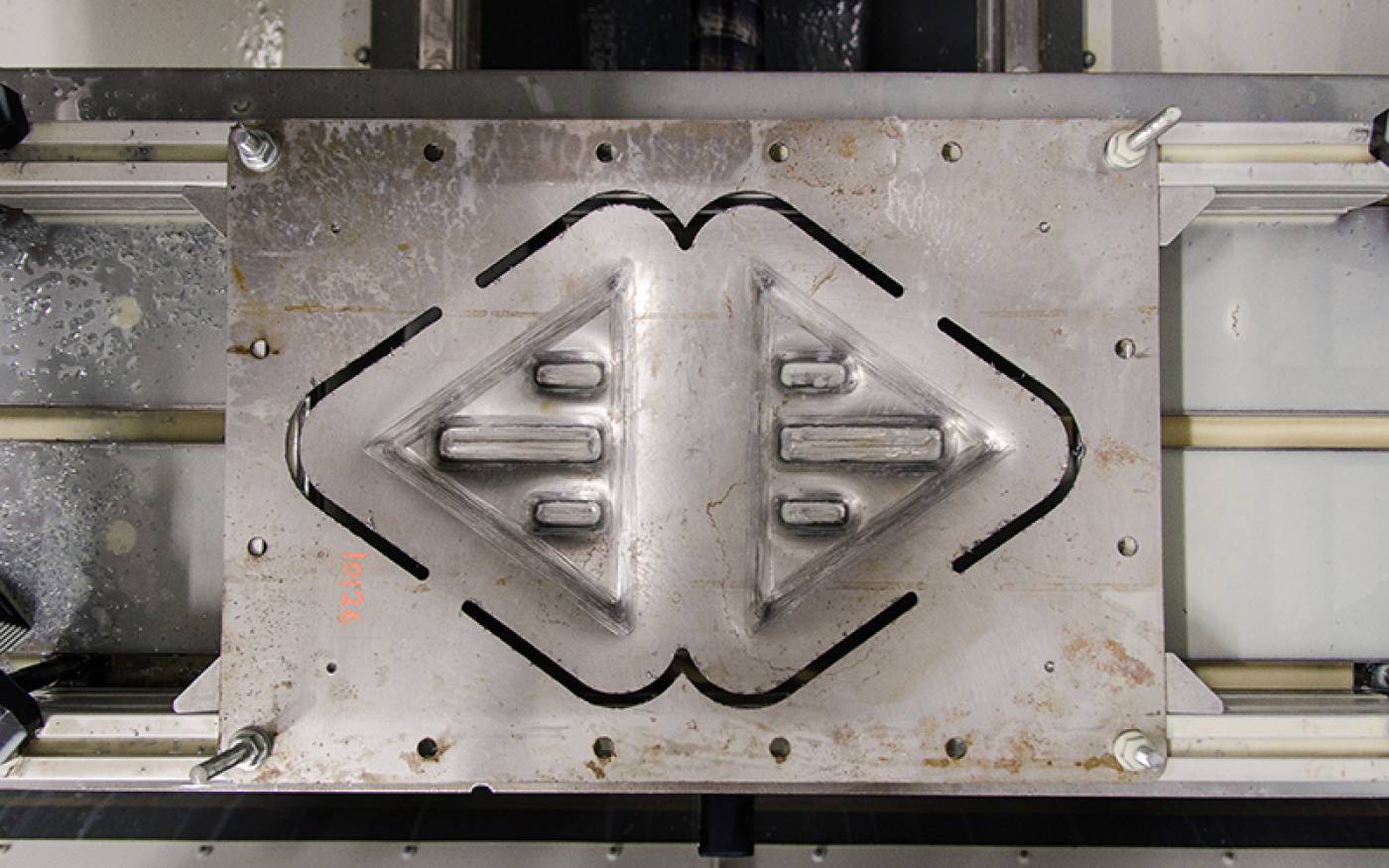

The upper and lower bounding surfaces are composed of 0.8mm thick mild steel sheet, and the ISF process was implemented on a three-axis milling machine with standard industrial extruded aluminium sections providing the workpiece holding. This achieved ISF depths of (200 to 250) mm within an inside frame size of 950x450mm.

Close

Close