Mariya Li

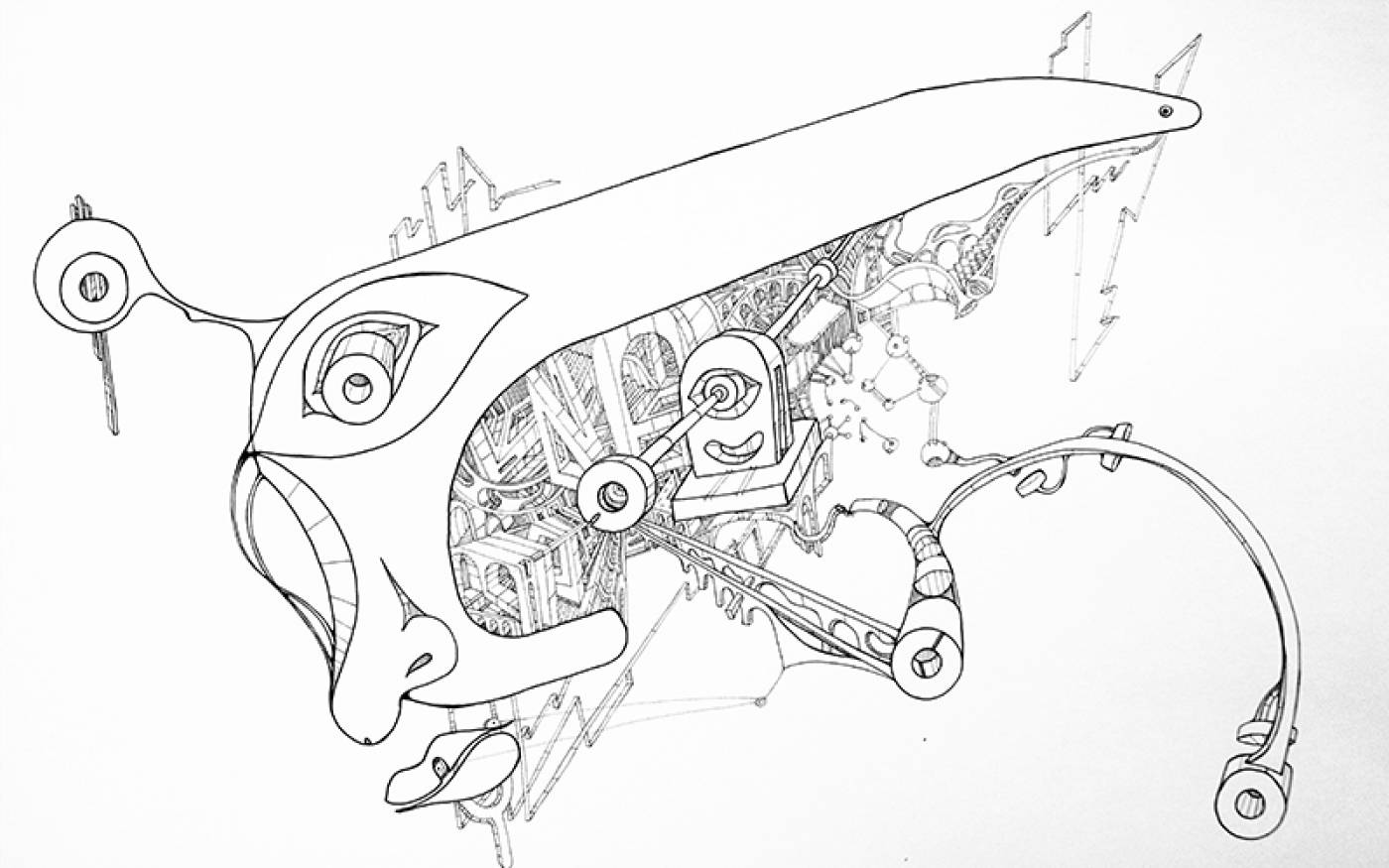

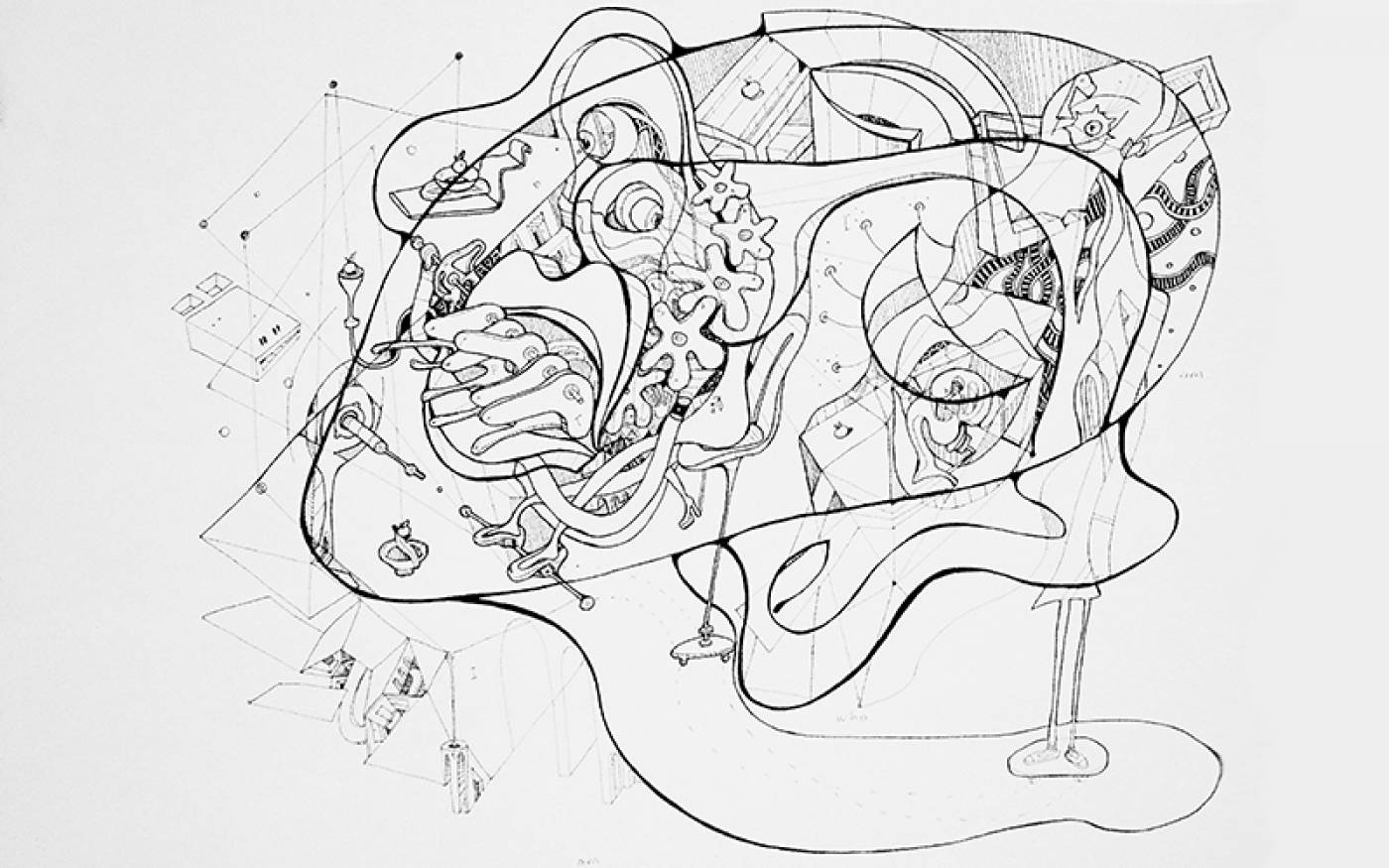

The starting-point of Fabricating for Percussion was a found component taken from an existing traditional musical instrument. The project fabricates for percussion to prolong the sustain time of a range of tones. The basis for selectively removing material from the overall profile has tested the relationship between the continuous internal perimeter of cut-out(s) and the overall profile area and the implications on the duration that the profile’s tone sustains.

The apparatus of this investigation compared the sustain duration of each fabricated profile. In each case the profile was percussed by a motor-operated striker turning at a controlled R.P.M. to give consistent strikes, and the resulting audio signal was analysed by comparing signal amplitude vs. time.

Profiles for percussion were fabricated by waterjet-cutting out of sheet metal, the hardware components were manually lathe-turned and CNC-milled from aluminium. For the given profile and the subtraction of material, the parameter space was explored by variations in the sheet thickness, metal type and striker base material. Repeated testing and comparison of each profile’s percussion properties directed the development of the profile’s geometry model to prolong the duration of the sustain in the tone produced.

Close

Close