UCL CARDIOVASCULAR ENGINEERING LABORATORY

Lab Director:

Dr Gaetano Burriesci

Address:

Roberts Building

UCL Mechanical Engineering

University College London Torrington Place

London WC1E 7JE

Tel: +44 (0)20 7679 3922

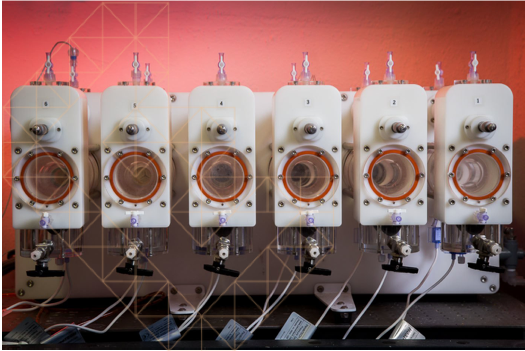

In Vitro Cardiovascular Hydrodynamic Testing System

To assess the performance of prosthetic heart valves under simulated cardiac conditions, we use a ViVitro Pulse Duplicator (ViVitro Labs, Inc., Victoria, BC, Canada).

The system simulates physiological or other complex pressure variations of the heart function, providing detailed quality data for heart valve and system performance.

Our customised apparatus includes compliant aortic chambers with native mock leaflets for percutaneous implants assessment, micro-tip pressure transducers, aortic and mitral electromagnetic flowmeters, physiological temperature control, ultrasound viscometer for continuous monitoring of the blood equivalence of the testing fluid, additional access ports for transcatheter implantation and high speed cameras for analysis of the valve dynamics. The system is controlled with a software developed in house, allowing additional flexibility, and is coupled with PIV facilities for the visualisation and measurement of the flow parameters.

To predict the durability of heart valves, we use the VDT-3600i Heart Valve Accelerated Wear Tester (Biomedical Device Consultants and Laboratories, CO, USA). This provides temperature control and continual monitoring of the real-time differential pressures in all test stations to verify the adherence to ISO 5840 testing requirements. Also, it enables individual station alarm capabilities to halt the system in case any sample exceeds its loading requirements.

Our system, which includes up to 12 testing sections, is specifically customised to host compliant mock arteries and assess stented tissue, stentless, mechanical, percutaneous and transcatheter valves.

Particle Image Velocimetry (PIV) can provide significant support to the understanding of the hemodynamics in normal and altered conditions.

We use a TSI 2-D PIV system, including two 70 mJ pulsed laser, lightsheet optics, a synchroniser, and a 4MP-HS camera.

The system is integrated with our cardiovascular hydrodynamic testing machine

Material Testing

For uniaxial testing, we use a zwickiLine testing machine (Zwick/Roell, Germany), which is specially designed for mechanical testing applications involving low test-loads. The apparatus allows tensile, compression and flexure tests, under quasi-static loading with continuous, static, pulsating or alternating load sequences via an electro-mechanical drive. Our machine is equipped with a media container with temperature control unit, and cryostat. This allows to perform tests maintaining physiological body conditions, and vary the media temperature from -20 °C to 120 °C, for the determination of the material parameters of devices made of nitinol.

For high test-loads, we also have access to the testing facilities at UCL Mechanical Engineering.

Software Capabilities

We have available a number of softwares for 3D CAD, implicit and explicit numerical simulations, FSI analyses, system design and other technical applications.

For 3D modelling, we use CATIA, the world leading solution for product design, and Rhinoceros, a stand-alone, commercial NURBS-based software suitable for engineering design, CAD/CAM, and rapid prototyping.

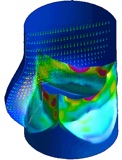

FEA, CFD and FSI

For Finite Element Analyses we have available a selection of implicit software such as MSC Patran, MSC Nastran, ANSYS, ABAQUS and Marc/Mentat; and explicit software, also suitable for FSI, such as LS-DYNA and MSC Dytran.

For CFD we use Star CD.

Photoelastic Stress Analysis

The determination of stress parameters is performed automatically by means of RGB and phase stepping methods.

Our equipment includes machines for rapid prototyping by additive manufacturing or 3D printing technologies, based on fused deposition modeling and stereolithography (we can print layers of 25 µm with features 300 µm) with standard and functional resins. Moreover, we also have access to the advanced manufacturing capability at UCL Mechanical Engineering and at the ‘Institute of Making˙

For accurate prototyping of medical flexible components we use a computer-controlled sewing and embroidery machine, to precisely extract suture lines from CAD files.

We also have a long experience in the use of casting and dip-molding of polymeric materials, for the creation of functional components and mock anatomies.

Facilities

UCL Home » UCL Department of Mechanical Engineering » Research » Biomechanical » UCL Cardiovascular Engineering Laboratory

University College London - Gower Street - London - WC1E 6BT Tel: +44 (0)20 7679 2000

© UCL 1999–2013