Sonocrystallisation is a complex process which takes advantage of ultrasound insonation to enhance the crystallisation process. The main attributes of the sonocrystallisation process are:

- fast nucleation rate;

- promoting nucleation at low supersaturation levels;

- yielding fine crystals with a narrow crystal size distribution.

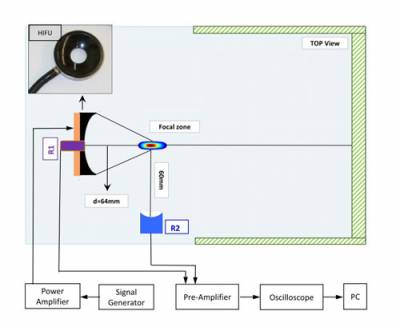

Diagram of in-house developed test setup for sonocrystallisation experiments. A HIFU transducer together with focused PCDs are used to control and monitor the ultrasound field.

These attributes make soncrystallisation an appealing manufacturing method in different industries, for example in the pharmaceutical sector. Implementation, however, requires detailed study and control of the process. Ultrasound parameters along with the properties of solution and crystallisation protocol influence sonocrystallisation. Therefore, it is necessary to study the interaction between the physics of ultrasound together with its associated effects, and the physics of crystallisation, which is modelled as a thermodynamic process.

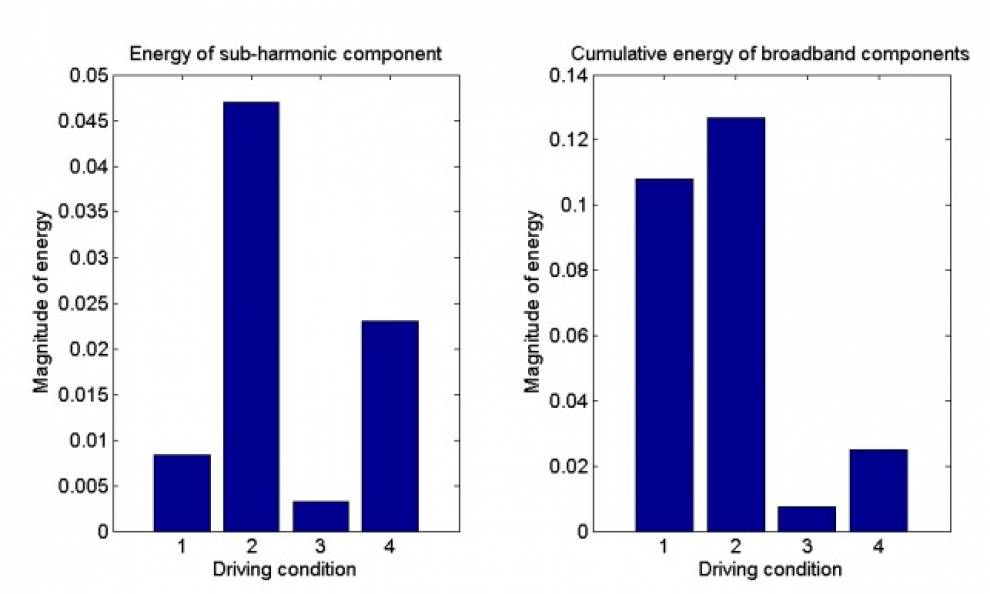

Magnitude of energy of inertial cavitation manifested in broadband and sub-harmonic components of PCD data. A HIFU transducer was drived at 1.1MHz and four different amplitudes. The estimated peak-to-peak pressure at focus are 5.6, 8, 14.5 and 19.6 MPa labled 1-4, respectively. These results are obtained using a new multi-resolution technique that was developed for this purpose.

This work aims to achieve a deeper insight about the interaction between sonication and crystallisation processes. The main objective is to understand the physics of the sonocrystallisation process and advance the knowledge of mechanisms.

This project is being conducted in collaboration with the Crystallisation Group in Chemical Engineering department, UCL, and is funded via the Engineering and Physical Sciences Research Council grant number EP/1031480/1.

Seyyed Reza Haqshenas

Close

Close