UCL CARDIOVASCULAR ENGINEERING LABORATORY

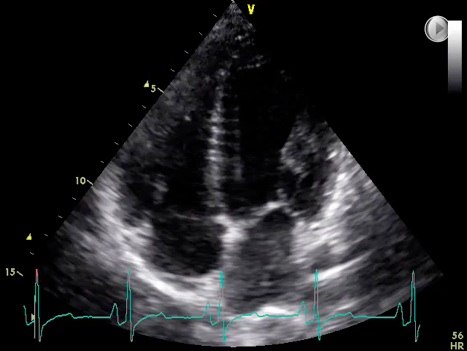

Mitral regurgitation (MR) is one of the most common forms of heart valve disorder, occurring when blood leaks from the left ventricle into the left atrium. If untreated, MR results into increased heart load and failure risk. It is estimated that symptomatic MR affects over four million Europeans and, due to the continuous ageing of our population, the number of cases is expected to rise significantly in the future.

In recent years, the need for less invasive therapeutic approaches has led to the development of a number of reconstructive percutaneous treatments for MR. However the available approaches mainly contribute to alleviate the symptoms and are suitable for very specific forms of mitral valve disease and anatomic subset. The possibility to perform a complete percutaneous mitral valve replacement still represents an unmet need which would provide enormous advance for a vast patients population.

Percutaneous and transcatheter valve replacement have already been successfully applied in the treatment of pulmonary and aortic valves. However, despite the relevance of the described clinical need, these approaches have not been successfully transferred to the mitral valve, due to the technical challenges associated with the geometry of the anatomical site and the more severe loading conditions.

The objective of this project is to expand the benefits of transcatheter valve replacement to the mitral valve, developing a novel prosthetic device suitable for this application.

If the proposed device will meet the expectations, this project will give a striking contribution to the development of an alternative treatment of heart valve dysfunctions. The principal beneficiaries will be patients suffering from heart valves diseases, with particular advantage for the categories that are excluded from current surgical practice.

Public health and industry will benefit from a transformative step towards a more sustainable new generation healthcare. In fact, once developed and assessed, this novel approach would make possible to quickly perform heart valve functional replacements in cardiac catheterisation laboratories and with shorter recovery time, thus reducing dramatically the costs to ensure proper treatment to the population. The reduction in costs and resources would contribute to enable valve replacement operations in many parts of the world where they are currently limited or not available, due to the resource-intensive requirements of surgery.

MAIN RELATED PUBLICATIONS

Burriesci, G., Zervides, C., Seifalian, A. M. (2010). Heart valve prosthesis. Patent WO2010112844 A1

Burriesci, G., Tzamtzis, S., Seifalian, A. M. (2012). Prosthesis delivery system. Patent WO/2012/052718

Percutaneus Mitral Valve

expanding the benefits of percutaneous valve replacement

to the mitral valve

RESEARCH TEAM

Gaetano Burriesci (PI)

Design, development and qualification

Selim Bozkurt (Research Associate)

Optimisation, manufacturing and in-vitro testing of the device

Georgia Preston-Maher (Res. Student)

Design, manufacturing and in-vitro testing of the device

Mike Mullen (Co-Investigator) ‘

Consultant cardiologist expert in percutaneous intervention techniques

Ryo Torii (Co-Supervisor)

Numerical simulation of the mitral valve

John Yap (Co-Investigator) ‘

Lead surgeon in the Transcatheter Aortic Implantation (TAVI) programme at UCL

‘ UCL Heart Hospital

EXTERNAL COLLABORATORS:

FUNDED BY:

UCL Home » UCL Department of Mechanical Engineering » Research » Biomechanical » UCL Cardiovascular Engineering Laboratory

University College London - Gower Street - London - WC1E 6BT Tel: +44 (0)20 7679 2000

© UCL 1999–2013