Shared Personal Protective Equipment (PPE)

This guidance applies to all activities where a risk assessment has determined it is suitable for PPE to be shared.

On this page

- Risk assessment

- Cleaning and disinfection

- Cryogenic and thermal protection gloves

- Sessional use of shared PPE

- Storage of shared PPE

- Documentation

This guidance applies to any personal protective equipment (PPE) used at UCL in a work activity to protect against non-COVID-19 risks. This includes any shared PPE used at UCL prior to the COVID-19 pandemic, to ensure it can continue to be used in such a way that the equipment is suitable for its intended use and there are no increased health risks to any person who uses it.

PPE is the last control measure on the hierarchy of controls as it is for individual use and thus provides protection only to the individual and not the collective. Although individual issue of PPE remains the UCL default position, there are some instances where the risk assessment for the activity may determine that specific PPE is deemed suitable for sharing.

The risk assessment must consider the factors in this guidance and establish measures to ensure shared PPE is properly cleaned and, where required, disinfected to ensure there are no health risks to any person who uses it.

Examples of shared PPE at UCL include but is not limited to:

- Face shields

- Cryogenic/heat protective gloves

- Welding helmet/shield (excluding RPE)

- Fall arrest harness

This does not apply to PPE that is used in a medical setting, including UCLH and RF NHS Trust. Where people are working on an NHS site they should follow the site's rules and contact their line manager before beginning a task if they feel unsafe.

Risk assessment

When conducting a risk assessment to determine if PPE is suitable to be shared, the equipment must be reusable and able to be cleaned and/or disinfected.

If cleaning/disinfection is not practicable e.g. for specialist glove types, then arrangements must be such that direct contact with the user is prevented. The following criteria must then be met:

- The PPE is used for limited periods of time; or

- The PPE is used infrequently; or

- The PPE is used both infrequently and for limited periods

These terms can be generally, but not explicitly, defined. It changes depending on the type of equipment and the work activity involved. It requires the discretion of the responsible persons for the work activity and/or equipment to determine which of the criteria match. If none of the criteria are met then the PPE is not suitable for sharing.

The risk assessment should identify the residual risk if PPE was to be individually allocated and whether this is greater than the risk of sharing PPE. This includes the safe storage, asset management and potential for items to be mixed during the course of a work activity or whilst users are on a break.

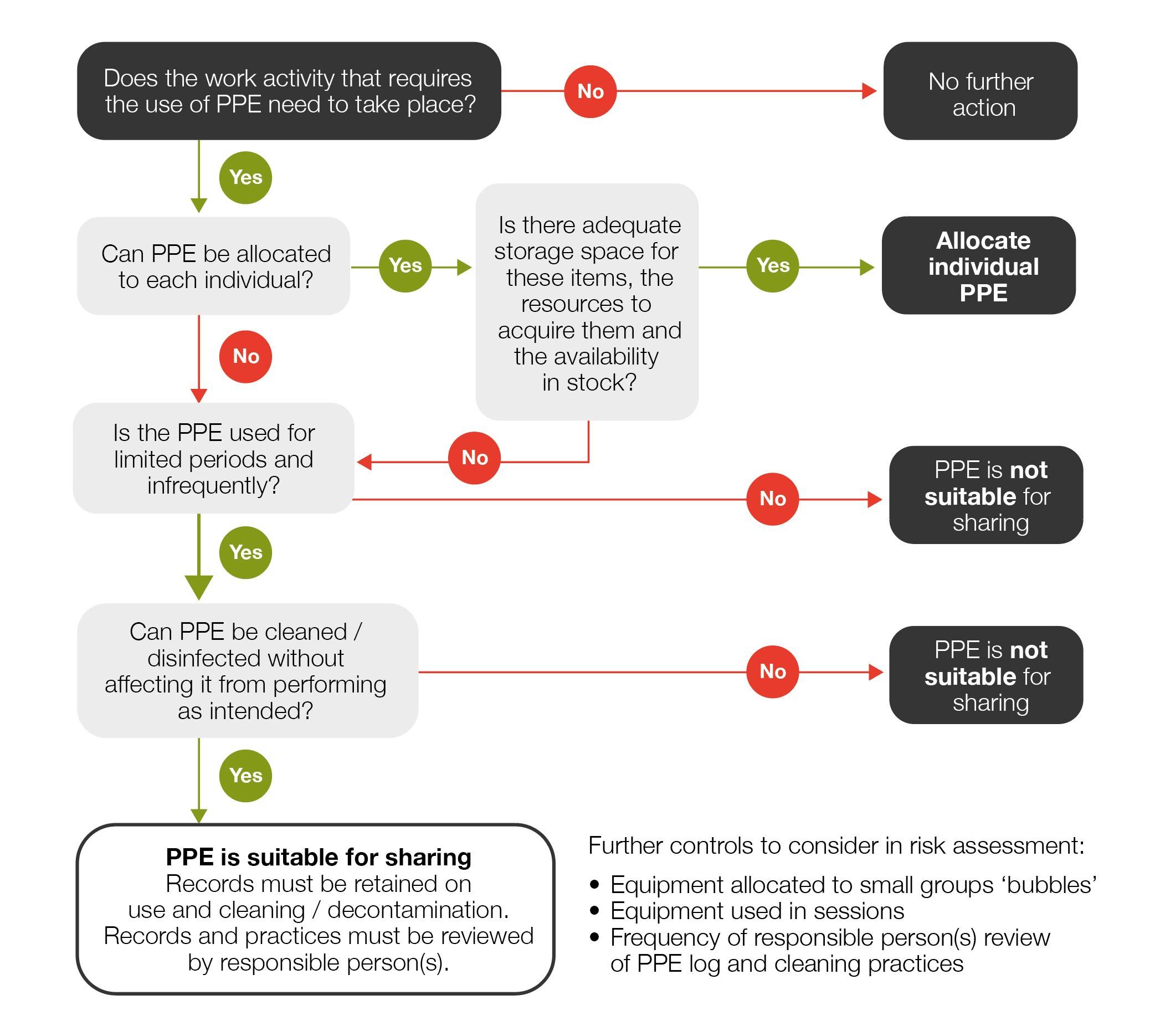

Guide to assist in shared PPE risk assessment

Route 1 - Does the work activity that requires the use of PPE need to take place? Route 1 The work activity does not need to take place, no further action, End

Route 2 - Does the work activity that requires the use of PPE need to take place? Route 2 The work activity does need to take place, PPE can be allocated to each individual, there is adequate storage space for the items, the resources to acquire them and the availability in stock, allocate individual PPE, End

Route 3 - Does the work activity that requires the use of PPE need to take place? Route 3 The work activity does need to take place, PPE can be allocated to each individual, there is not adequate storage space for the items, or the resources to acquire them and the availability in stock, PPE used for limited period and infrequency, PPE can be cleaned/disinfected without affecting it from performing as intended, PPE is suitable for sharing, End

Route 4 - Does the work activity that requires the use of PPE need to take place? Route 4 The work activity does need to take place, PPE cannot be allocated to each individual, PPE can be used for limited periods and infrequently, PPE can be cleaned/disinfected without affecting it from performing as intended, PPE is suitable for sharing, End

Route 5 - Does the work activity that requires the use of PPE need to take place? Route 5 The work activity does need to take place, PPE cannot be allocated to each individual, PPE cannot be used for limited periods and infrequently, PPE is not suitable for sharing, End

PPE used for limited periods of time

PPE used for limited periods is equipment that is not required to be used for the duration of a work shift or the entirety of a work activity.

- Equipment worn to undertake a specific task as a small part of the work activity and for the protection of the user from the hazards associated with the task (e.g. such as working with cryogenic substances)

- Generally these tasks would be measured in terms of minutes rather than hours

PPE used infrequently

PPE used infrequently is equipment that is not required to be used on a regular basis during normal working patterns. This could be equipment used for a certain task during the work activity.

- Wearing a welding helmet for welding activities that take place once every 2 weeks

- Wearing a face shield when storing/removing cryogenic samples from liquid nitrogen that is done a couple of times a day

- A task carried out by a student once or a minute amount of times

PPE used by small groups

To further mitigate the risk, items of shared PPE can be assigned to the same group of people (a bubble) who will share the use of that item.

This may cause difficulties if users need to use the equipment at the same time but it provides a greater element of management control.

The size of the group will be relative to the amount of users authorised to use the equipment, the work activities taking place and how many pieces of equipment are available. For example, a department has 30 competent members of staff who can use an item of equipment and 20 have returned to work. The work activity requiring that item of equipment usually takes place in 4 laboratories and now takes place in 2 laboratories. There are 4 pieces of equipment available to share in that department. The ‘small groups’ may be dissected into 4 groups of 5 to share an item of equipment between them.

The smaller the group, the greater the overall control of the equipment. Where possible, departments may seek to procure more items of equipment to create smaller bubbles. This could control the risk as low as reasonably practicable where it is difficult to acquire individual items of PPE and the resources are not available.

Cleaning and disinfection

For PPE to be suitable for sharing, it must meet the criteria above and it also be reusable and able to be cleaned/disinfected. If the PPE cannot be cleaned and disinfected then the equipment is not suitable for sharing.

The cleaning of PPE must be done in accordance with manufacturers’ instructions and must be carried out in a way that would ensure the equipment performs as intended.

Any cleaning agents/materials used must be compatible with the equipment and not jeopardise the integrity in such a way that the equipment will fail to perform as intended.

For effective disinfection of equipment, substances or cleaning wipes used should have a minimum 70% alcohol content, unless otherwise specified in the manufacturers’ instructions or if this will create an additional risk when using the item. In this instance the substance used must be effective against enveloped viruses. The disinfection by cleaning wipes must be done before use and immediately after use.

Other disinfection methods, for example total immersion of the PPE, may be considered in the risk assessment. The risk assessment would need to determine that the method used did not introduce risks associated with the amount of disinfectant required and that it does not affect the integrity of the PPE both in the short and long term. Consideration would also be needed on how often the disinfectant should be changed to maintain efficacy and the time required to dry the PPE after immersion.

Instruction must be available, ideally at the point of use, on how to clean the item and who is responsible for the cleaning. In most cases this should be the user to prevent unnecessary exposure.

Cryogenic and thermal protection gloves

The use of cryogenic and thermal protective gloves are the exception to the cleaning rule. This equipment can be shared without needing to disinfect it.

Other control measures are required to prevent contact of the skin with the inside of the gloves. Users must:

- Wash their hands with soap and water for at least 20 seconds before using the gloves

- Effectively dry their hands

- Put nitrile gloves on as a measure to prevent skin contact with the inside of the gloves

- Use the gloves as intended

- Remove the nitrile gloves and dispose of them appropriately

- Wash their hands with soap and water for 20 seconds after using the gloves

Sessional use of shared PPE

Items of shared PPE can also be allocated for sessional use where the PPE is used by one worker during one shift.

This is a further mitigation to ensure that a worker can take the item of PPE off during breaks and be assured it is not in use by another worker and will be ready for their use again after the break. This would be an extra precaution and not a replacement of a thorough clean and disinfection before and after use.

Storage of shared PPE

All PPE requires adequate storage in line with manufacturers’ instructions to protect it from damage and contamination.

Whilst it is preferable to have PPE allocated to each person for individual use there will also need to be adequate storage facilities for this equipment. If there is not, this creates a greater residual risk. This means that the suitable sharing of PPE may be preferable, this will be determined during the risk assessment process.

Documentation

For PPE to be suitable for sharing, records must be kept of:

- The date and time of use

- Who used it

- Confirmation it was cleaned/disinfected before use

- Confirmation it was cleaned/disinfected after use

These records must be traceable to each individual item of PPE, therefore it is advisable that items of shared PPE are asset marked with a unique identifier.

It is also the responsibility of managers, supervisors and principal investigators (PIs) to monitor the records of shared PPE use and cleaning, and the effectiveness of the cleaning taking place in line with manufacturers’ instructions.

> Download a Shared PPE Log (Word document)

Last updated: Wednesday, September 2, 2020

Close

Close