Many processes employing porous catalysts are plagued by significant diffusion limitations, which reduce yields and selectivity toward the desired products. Additionally, as a catalyst is left on-stream, undesired by-products of the reactions, such as coke, may lead to pore blockage and catalyst deactivation. Hierarchically structured catalysts include a desired distribution of active sites, and a network of broad pores that allow more facile access of the active sites and mitigate catalyst deactivation.

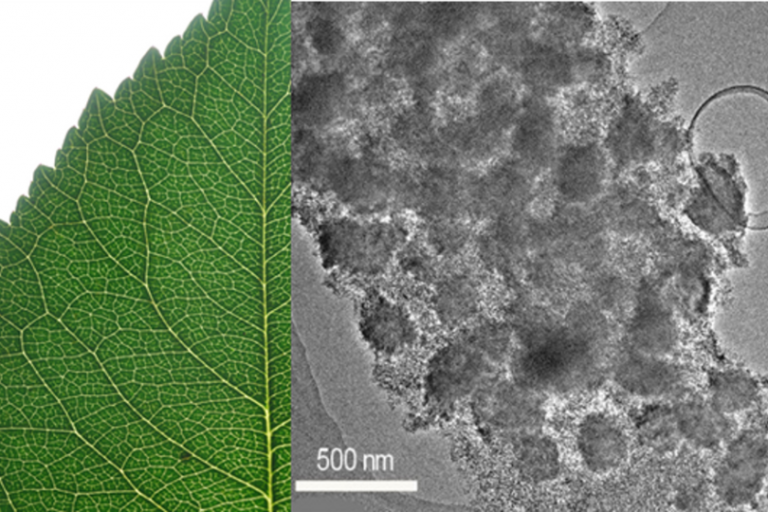

We use theory-assisted design to guide the synthesis of hierarchically structured, nanoporous catalysts with desired chemical and geometrical structure at all scales – from active site to pellet – and superior activity, selectivity and stability against deactivation. We keep reactor engineering constraints and opportunities in mind in our optimization.

Current Researchers: Mohammad Alkhunaizi, Aleksandra Glowska

Past researchers: Tobias Weissenberger

Collaborators: Guanghua Ye, East China University of Science and Technology (ECUST)

Key Publications

- M.-O. Coppens, T.Weissenberger, Q. Zhang and G. Ye, 2020, Nature-inspired, computer-assisted optimization of hierarchically structured zeolites. Adv. Mat. Int. DOI: 10.1002/admi.202001409 [Link]

- S. M. Rao and M.-O. Coppens, 2012, Increasing Robustness against Deactivation of Nanoporous Catalysts by Introducing an Optimized Hierarchical Pore Network - Application to Hydrodemetalation, Chem. Eng. Sci., 83, 66. (Special Issue for MACKIE)

[Link] - S.M. Rao and M.-O. Coppens, 2010, Mitigating deactivation effects through rational design of hierarchically structured catalysts -- Application to hydrodemetalation", Ind. Eng. Chem. Res., 49, 11087. (Special Issue for ISCRE 21). [Link]

- G. Wang and M.-O. Coppens, 2010, Rational design of hierarchically structured porous catalysts for autothermal reforming of methane", Chem. Eng. Sci., 65, 2344. [Link]

Close

Close