Please find below list of equipment and in situ rigs in the MSM@H Group.

- Blown Additive Manufacturing Process Replicator (BAMPR)

- Quad - In-Situ and Operando Process Replicator (Quad-ISOPR)

- P2R In-Situ Micromechanics Test Rig

- Viking Tensile Rig

- Deben CT5000 Rig

- Stella Furnace

- Laura Furnace

- Alice Furnace

- Cold Stage

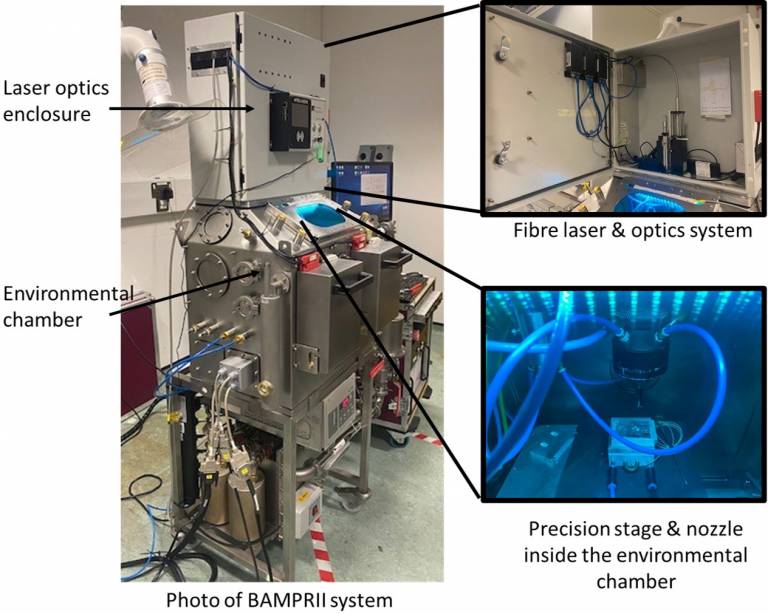

Blown Additive Manufacturing Process Replicator (BAMPR)

BAMPR-2 Unique Directed Energy Deposition Blown Powder Additive Manufacturing Machine that works on a synchrotron beamline, enabling concurrent x-ray, optical, and IR imaging of the laser-matter interaction, including the weld pool, solidification, etc

Features:

- 500W laser

- Controlled atmosphere

- Translation or rotation stage

- Wide range of materials, SS, Al, Ti and Ni alloys

- Ability to do coatings

- Use in on site laboratory or at DLS or ESRF synchrotrons

- Photron S12 Nova high speed optical camera (up to 1MHz with a reduced field of view)

- FLIR high speed IR camera

Contact: Peter Lee

Back to Top

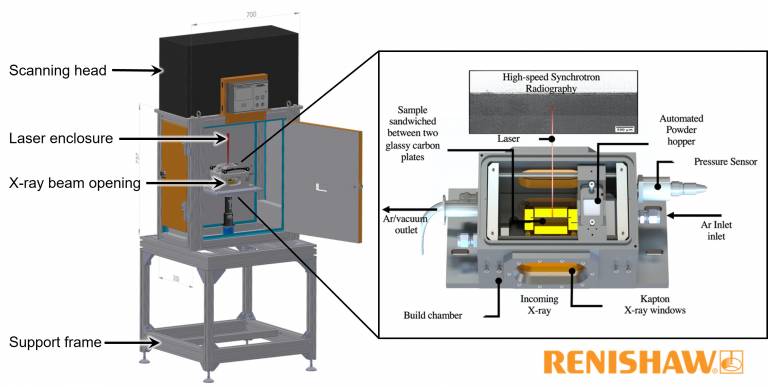

Quad - In-Situ and Operando Process Replicator (Quad-ISOPR)

Quad laser In situ and Operando Process Replicator a co-developed physical twin that mimics the Renishaw Ren500QAM machine that works on both lab and synchrotron beamline(s), enabling concurrent X-ray, chemical, optical, and IR imaging of the laser-matter interaction, including the weld pool, solidification, etc.

Features:

- 4x 500W lasers (1070 nm)

- Controlled atmosphere

- Automated powder hopper

- Variable gas flow

- Wide range of materials, including ceramics, metals/alloys, polymer, glass, and composites.

- Use on-site laboratory or at DLS, ESRF, and other synchrotron radiation facilities

- Coaxial optical image with Photron S12 Nova (up to 1MHz with a reduced field of view)

- Off-axis IR imaging.

Contact: Chu Lun Alex Leung

Back to Top

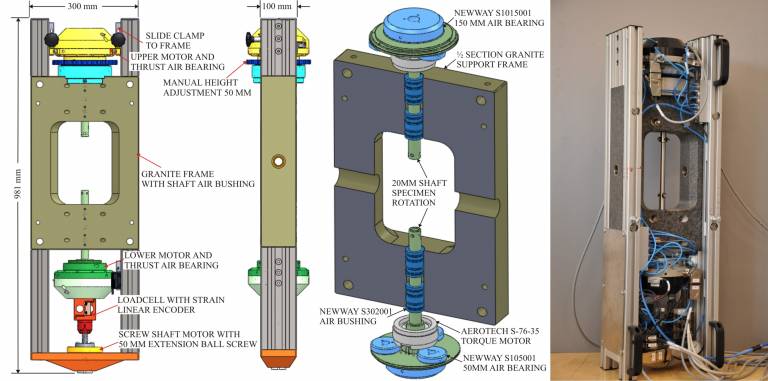

P2R In-Situ Micromechanics Test Rig

Features:

- Unique tension/compression/torsion rig.

- -80 to 1600 °C.

- Load cell up to 750 N.

- Continuous air bearing rotation for 50 nm accuracy in motion.

- On site laboratory or at DLS, SLS, ESRF synchrotrons.

- Grips/rams for tension/compression, extrusion, crack growth, shear, 3-point bending.

- Special environments for (a) simulate aero-engine component manufacture; (b) magma flows; (c) knee joint mechanics; and (d) bio-reactors.

Contact: Saurabh Shah

Back to Top

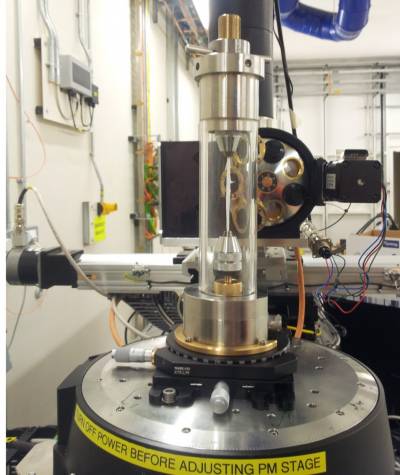

Viking Tensile Rig

Features:

- Up to 1800 °C + environment.

- For TXM, commissioned on I12 beamline.

- For laboratory or synchrotron use, transportable.

Contact: Saurabh Shah

Back to Top

Deben CT5000 Rig

Features:

- -20 to 160 °C, tension, compression.

- For laboratory or synchrotron use.

- Transportable.

Contact: Saurabh Shah

Back to Top

Stella Furnace

Features:

- 1800 °C + environment.

- For TXM, commissioned on I12 beamline.

- For laboratory or synchrotron use, transportable.

Contact: Saurabh Shah

Back to Top

Laura Furnace

Features:

- 1000 °C and large samples, light alloys and bio-glasses.

- Inert gas flow.

- For laboratory or synchrotron use, transportable.

Contact: Saurabh Shah

Back to Top

Alice Furnace

Features:

- 1550 °C + environment.

- Similar to the Stella Furnace, but improved ease of use.

- For laboratory or synchrotron use, transportable.

Contact: Saurabh Shah

Back to Top

Cold Stage

Features:

- -40 to +60 cold stage for biological to food sample.

- Highly stable, programmable temperature ramping.

- For laboratory or synchrotron use, transportable.

Contact: Saurabh Shah

Back to Top

Close

Close