The science behind the research

Thermal barrier coatings (TBCs) are advanced materials used as coatings on turbines or aircraft engines for materials protection against excessive heat in high-temperature processes. Typical oxides used as TBCs include yttria-stabilized zirconia (YSZ). Typical failure occurs due to thermal fatigue, accelerated oxidation, hot corrosion or molten deposit degradation. There is a need for TBCs that can withstand higher temperature during extended periods of time.

| Fig 1. Turbine with thermal barrier coating |

|

Novel ceramic oxides based on rare earth doped ZrO2 such as Dy2O3 doped Y2O3 stabilized ZrO2 (Dy-YSZ) or conjugated with lanthanum titanium aluminium oxide, can be used in various applications including high temperature applications, structural applications and medical applications.

Electrospray assisted vapour deposition (ESAVD) has achieved particularly interesting results on TBCs deposition. ESAVD is a non-vacuum, eco-friendly, efficient, low-cost process that can be used to improve performance of metal oxides coatings used as thermal barriers.

Ongoing research

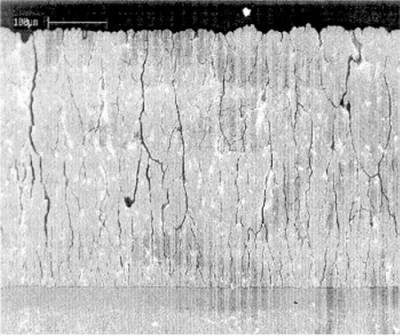

TBC coatings produced at the Institute for Materials Discovery produced using ESAVD method have shown to be highly thermal-resistant, erosion resistant, uniform, stress-strain tolerant due to column-like structure, and to have lower thermal conductivity.

| Fig 2. Column-like structure of ESAVD processed TBC coating |

|

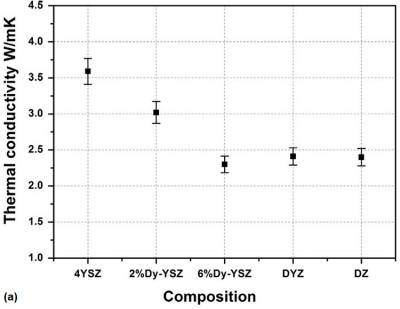

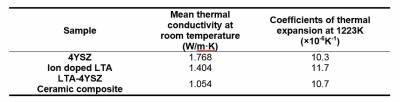

At the Institute for Materials Discovery we use a combination of modelling and experimental approaches to design, manufacture and characterise novel rare-earth doped ceramic oxides to be used as TBCs. We have achieved low thermal conductivity doped or conjugated ZrO2 when compared with the conventional materials.

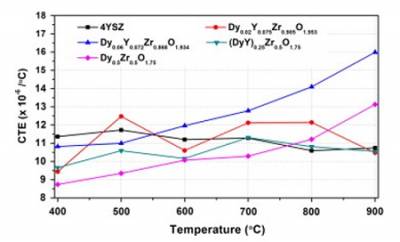

The coefficient of thermal expansion of the multi-component doped ZrO2 has been improved as compared with that of 6-8 wt. % YSZ.

| Fig 3. Comparison of the thermal conductivity via experiment and the simulation at room temperature of rare earth doped ZrO2. See Recent publications below |

|

| Fig 4. - Comparison of the coefficient of thermal expansion via experiment and the simulation at room temperature of rare earth doped ZrO2. See Recent publications below |

|

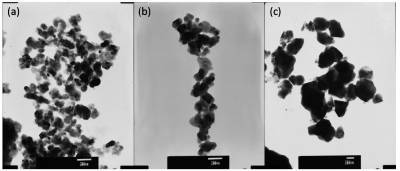

| Fig 5. TEM morphology of LTA calcined at different temperature: (a) 1100oC, (b) 1200oC, (c) 1350oC |

|

| Table 1. Densities and thermal conductivities of LTA, 4YSZ, and LTA-4YSZ |

|

Recent publications

- Qu, L., Choy, K. L., & Wheatley, R. (2016). An Atomistic-Scale Study for Thermal Conductivity and Thermochemical Compatibility in (DyY)Zr2O7 Combining an Experimental Approach with Theoretical Calculation. Scientific Reports, 6, 21232. doi:10.1038/srep21232

- Zhang, P., & Choy, K. L. (2016). The studies of a new ceramic composite - (Zr0.92Y0.08)O-1.96 dispersed lanthanum titanium aluminium oxide. Scripta Materialia, 115, 24-27. doi:10.1016/j.scriptamat.2015.12.033

- Wang, J., Xu, F., Wheatley, R. J., Choy, K. L., Neate, N., & Hou, X. (2015). Investigation of La3+ Doped Yb2Sn2O7 as new thermal barrier materials. Materials & Design, 85, 423-430. doi:10.1016/j.matdes.2015.07.022

- Qu, L., & Choy, K. L. (2014). Thermophysical and thermochemical properties of new thermal barrier materials based on Dy2O3-Y2O3 co-doped zirconia. Ceramics International, 40, (8), 11593-11599. doi:10.1016/j.ceramint.2014.03.129

Close

Close