The science behind the research

CIGS (copper indium gallium selenide) based solar cells are currently the most efficient thin film systems for photovoltaic applications. The main challenges of commercial CIGS cells are related to their high cost and to the low deposition rates achieved in the physical vapour deposition techniques that are usually employed to manufacture them.

At IMD, we focus our research on lowering the cost of CIGS solar cells and on the development of a non-vacuum manufacturing process that has the potential of being easily scaled-up. A cutting edge Electrostatic Assisted Vapour Deposition (ESAVD) method that allows depositing CIGS thin films with high efficiency, high uniformity and no secondary phases under non-vacuum conditions has been developed.

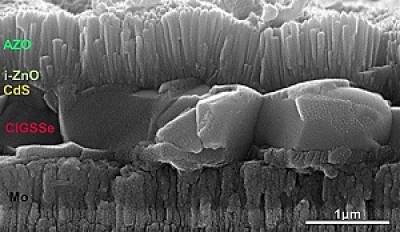

| Fig 1. SEM cross section of CIGS solar cell |

|

Ongoing research

Our most recent results show that fully non-vacuum processed CIGS solar cells using electrodeposited absorbers and Ag nanowires-based transparent conductive oxides achieve efficiency of above 14%.

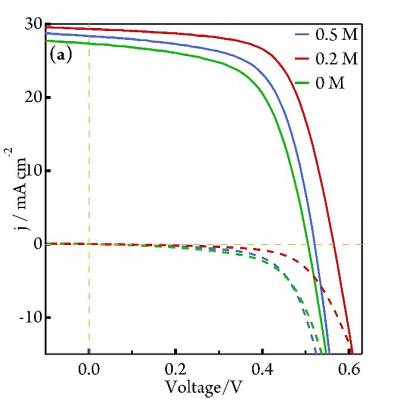

| Fig 2. IV curve for CIGS solar cells |

|

Recent publications

- Wang, M., Hossain, M. A., & Choy, K. L. (2017). Effect of Sodium Treatment on the Performance of Electrostatic Spray Assisted Vapour Deposited Copper-poor Cu(In,Ga)(S,Se)2 Solar Cells. Scientific Reports, 7 (1), 6788. doi:10.1038/s41598-017-07027-9

- Wang, M., & Choy, K. L. (2016). All-Nonvacuum-Processed CIGS Solar Cells Using Scalable Ag NWs/AZO-Based Transparent Electrodes. ACS Applied Materials and Interfaces, 8 (26), 16640-16648. doi:10.1021/acsami.6b02137

- Hossain, M. A., Wang, M., & Choy, K. L. (2015). Ecofriendly and Nonvacuum Electrostatic Spray-Assisted Vapor Deposition of Cu(In,Ga)(S,Se)2 Thin Film Solar Cells. ACS Applied Materials and Interfaces, 7, 40, 22497–22503. doi: 10.1021/acsami.5b06666

- Wang, M., Hou, X., Liu, J., Choy, K. L., Gibson, P., Salem E., Koutsogeorgis, D., & Cranton, W. (2015). An alternative non-vacuum and low cost ESAVD method for the deposition of Cu(In,Ga)Se2 absorber layers. Physica Status Solidi A 212, 1, 72-75. doi: 10.1002/pssa.201431295

Close

Close