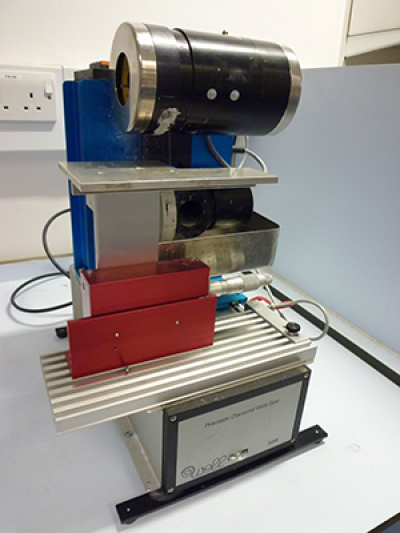

Well, Model 3241

|  |

- Please note the Wire Saw is currently not available to use -

The BEIF lab hosts a Well Precision Diamond Wire Saw (Model 3241) for use in preparing materials for analysis. This precision diamond wire saw cuts materials such as bone, rocks, belemnites and speleothems.

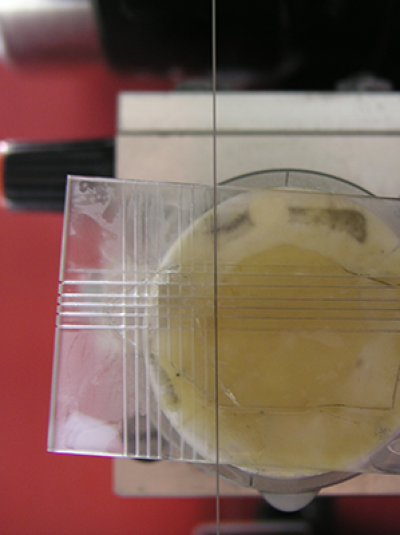

The saw cuts by moving a wire coated with abrasive diamond particles through a sample. A single strand of wire is used, fastened at each end, with a reciprocal movement. In this way, wire welds are avoided eliminating a weak point in the wire and giving smoother cut surfaces. Gravity is used to 7 force the wire through the sample through the use of a linear bearing. This applies a constant cutting force throughout the progress of the cut resulting in more predictable cutting times and workpiece temperatures. The tensioning pulley is partially submerged in a water bath providing cooling and cleaning of the cutting wire during use. A micrometer (with 0.010 mm. resolution) moves the sample perpendicular to the direction of cut, providing precise sample location and section thickness control. By varying the wire speed, slope of the saw, and size of diamond wire used, a wide variety of specimen hardnesses can be sectioned as thin as 30 microns.

A grooved table, which is attached to the stationary part of the saw, permits the fastening of any sort of component for holding the specimens. Included with the saw is a micrometer table for precise setting of the specimen thickness or cut location. Coarse setting is possible on the grooved table, with the micrometer table giving a fine setting to within 10 microns. Orientation plates are attached to this table which make it possible to cut the specimen axially or longitudinally. Specimen holders of various types are attached to the plates and are available for purchase from the manufacturer.

- Free to BEIF machine users; £10 per hour for others

Close

Close