Eric S Fraga: Research overview

Table of Contents

Overview of my research

My research lies at the interfaces between computer science, mathematics and chemical or industrial engineering. The focus of my research is the development and implementation of novel algorithms for decision support. The aim is to support the process of design in engineering with particular emphasis on the interaction between the engineer, and other stakeholders involved in making decisions, and the computer. Applications of my research are primarily in industrial engineering, including process design in general, energy reduction and generation, carbon capture and use, water distribution and power dispatch.

The research can be broadly placed into the following categories, each described in more detail in the following sections:

- Multi-criteria optimisation methods for large scale complex design problems.

- Visualisation and data analysis procedures for enhanced user interaction and for improved targeted optimisation procedures.

- The development of a generic framework to support design activities as well as the associated technologies for distributed computation and team-based working.

The optimisation, visualisation and data analysis methods developed are implemented in a number of different software packages:

- Fresa

- a multi-objective optimization system in Julia which implements a Plant Propagation Algorithm.

- Jacaranda

- a generic and extensible object oriented framework for process design, optimisation, data analysis, and visualisation.

- Strawberry

- a multi-objective optimization system, in Octave or MATLAB, which implements a Plant Propagation Algorithm.

A list of current research projects is presented below. A short presentation highlights some of my recent and ongoing projects.

Figure 1: An oil refinery in Edmonton, Alberta, Canada, my home town!

Return back to my home pages for contact details and other information.

Research publications

An automatically generated, hence almost up-to-date, list of publications is available on UCL Profiles. Lists are also available on my Google Scholar (the most comprehensive), ORCiD, ResearchGate, and Scopus.

A selection of recent publications, including link to freely available copy when available, is listed here:

- Fresa: a plant propagation algorithm for black-box single and multiple objective optimization

E S Fraga (2021), International Journal on Engineering Technologies and Informatics 4:110-111 (PDF). - Design optimization of microfluidic-based solvent extraction systems for radionuclides detection

M Pineda, D Tsaoulidis, P I O Filho, T Tsukahara, P Angeli, & E S Fraga (2021), Nuclear Engineering and Design 383 doi:10.1016/j.nucengdes.2021.111432. - Heating strategies in cellulose pyrolysis as an alternative for targeting energy efficient product distribution

A Chico-Proano, G Manos, L G Papageorgiou, & E S Fraga (2021), Transactions of Chemical Engineering 61–66, doi:10.3303/CET2186011. - Multiple simultaneous solution representations in a population based evolutionary algorithm

Eric S Fraga (2021), arXiv:2106.05096. - Experimental and CFD scale-up studies for intensified actinide/lanthanide separations

D Tsaoulidis, Milan Mamtora, Miguel Pineda, Eric S Fraga, Panagiota Angeli (2021), Chemical Engineering and Processing – Process Intensification 164, doi:10.1016/j.cep.2021.108355. - Hydrodynamics and mass transfer in segmented flow small channel contactors for uranium extraction

Eduardo Garciadiego-Ortega, Dimitrios Tsaoulidis, Miguel Pineda, Eric S.Fraga, Panagiota Angeli (2020), Chemical Engineering and Processing – Process Intensification 153, doi:10.1016/j.cep.2020.107921. - Application of Photo-Electrochemically Generated Hydrogen with Fuel Cell Based Micro-Combined Heat and Power: A Dynamic System Modelling Study

Krisztian Ronaszegi, Eric S. Fraga, Jawwad Darr, Paul R. Shearing, and Dan J. L. Brett (2020), Molecules 25:123, doi:10.3390/molecules25010123. - A diagnostic procedure for improving the structure of approximated kinetic models

Marco Quaglio, Eric S Fraga, & Federico Galvanin (2020), Computers & Chemical Engineering 133, doi:10.1016/j.compchemeng.2019.106659.

For prospective PhD students

If you are looking for a PhD position in my group, please email me with your research interests and indicate clearly the preference between programming and modelling projects as well as the potential domain of application.

After discussing the possibility of joining my research group, the next step would be apply formally. When filling in the form, please put my name as proposed supervisor as that will ensure that your application is brought to my attention. If you have any questions on the application process, please contact the PhD admissions tutor as noted on the application site.

Please note that I have no funding currently for a PhD position. Should funding be available, this will be indicated here and on the UCL Chemical Engineering department web site.

Optimisation

I am interested in the development of new optimisation procedures for tackling large and complex problems. By complex, I mean to include problems that may exhibit highly nonlinear behaviour with non-smoothness and possibly dis-continuities and/or problems with significant structural elements. Mathematically, the problems I am interested in are typically modelled by mixed integer nonlinear programming (MINLP), possibly including partial or ordinary differential equations, with multiple objectives. Often, the problems of interest lie in the domain of computationally expensive optimisation, optimisation problems where the objective function may take several seconds to minutes to evaluate. Such problems cannot be tackled through traditional methods which may expect to perform hundreds of thousands of function evaluations.

The research concentrates on the development of hybrid optimisation procedures, combining a number of different approaches in an automated framework1. The different approaches may include a section of stochastic, direct search and mathematical programming methods. The aim is to develop software that is robust in terms of always obtaining an answer to the problem regardless of the potential mathematical and numerical obstacles posed by the problem.

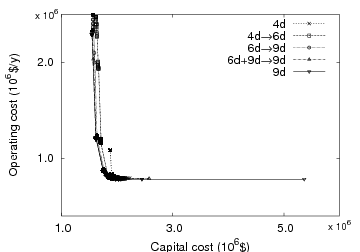

Figure 2: Evolution of Pareto front approximation for multi-objective optimisation problem generated through a novel iterative procedure.

The graph shows the results of an iterative multi-criteria optimisation method based on dimension reduction through principal component analysis. The optimisation procedure starts by solving the design problem in the search domain restricted to a 4 dimensional hyper-plane of the original 9 dimensional domain. The dimension of the hyper-plane is then successively increased through further data analysis.

The hybrid procedures are often under-pinned by visualisation and data analysis techniques,2 not only for the development of new methods3 but also for the presentation of results to the engineer.

Visualisation and data analysis

The key difficulty in using automated systems in process design is the complexity of the underlying problem. Especially in chemical engineering, the interactions between different elements in a process may be not only complex but not well understood. The use of automation can lull the engineer into believing that the results obtained by the solution approach is the best possible, without questioning the underlying models which lead to this solution. Visualisation, often with data analysis, can be useful in providing the engineer with extra information about the quality of the solution obtained and how it relates to the actual design space.

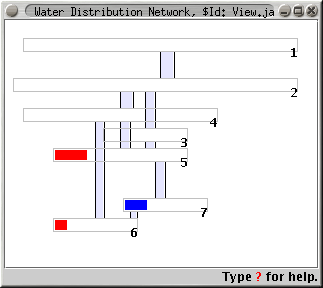

Figure 3: Graphical interface for optimisation of water distribution networks.

The figure shows a visualisation based interface for the design of water distribution networks, showing shortfalls (in red) and excess (in blue) in meeting demands.4 A screencast is available which shows the graphical interface in use. The screencast is 5 minutes long and it takes a while before anything happens: it's part of a presentation where I describe the interface during the first part of the animation.

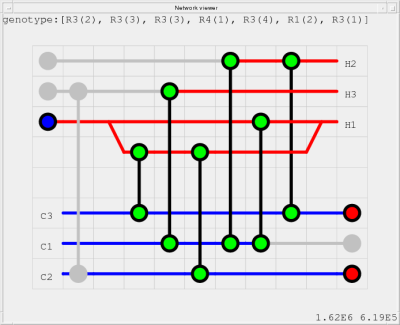

Figure 4: Graphical interactive interface for heat exchanger network design and process optimisation.

Another example is the use of a graphical interface for heat exchanger network design.5 The interface can not only be used to design the heat exchanger network for a given set of hot and cold process streams, it may also be used to modify an underlying process design to enhance the potential for heat exchange. The screencast (an animated GIF, exactly one minute long, just under 2MB in size) shows how the interface allows an engineer to explore whether better results can be obtained by asking for re-designs of process units (distillation in this example) which would lead to different specifications for the process streams. By increasing the operating pressure of two distillation columns in the example process, a better use of process integration can be achieved, meeting the cooling requirements of two units completely and the heating requirements of one unit. The net annualised cost, including both capital and operating costs of the process units and the heat exchangers, reduces by approximately one quarter.

The heat exchanger network design graphical interface is part of the Jacaranda system for automated design and process optimisation.

Data analysis and visualisation techniques may also be used to develop the optimisation procedure itself. These techniques may also be used interactively, simultaneously with an optimisation procedure, allowing the engineer to control the progress of optimisation through the use of insight gained during the procedure5.

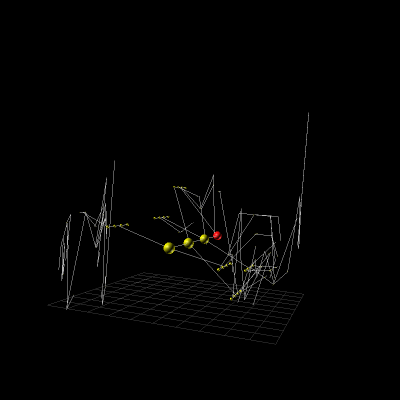

Figure 5: A three dimensional view of the design space with selected discrete designs and their connections to neighbouring solutions.

Jacaranda: A generic framework for design

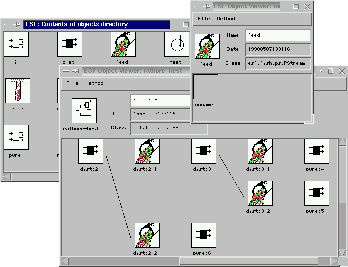

The development of novel algorithms is not sufficient without a means to access these algorithms. The Jacaranda system for process design and optimisation6 is a complete design tool which provides access to all the different methods developed in my group. Jacaranda is an generic and extensible framework, based on object oriented technologies, with both text-based and graphical interfaces. It is written in Java and is therefore portable to a wide range of computer systems. Further details, including licensing arrangements, can be found here. The system includes a graphical interface, shown here, for accessing the objects created in solving a problem.

Figure 6: Object manager in the Jacaranda system for automated design and process optimisation.

Although Jacaranda is intended to provide full support for many engineering design tasks, the repertoire of computer tools an engineer has access to is large. Furthermore, an engineer seldom works in isolation; team-based design is the norm. A design team may also be distributed geographically. As a result, I am also interested in the development of full distributed application environments which provide access to disparate tools and which allow the design team to work together. An EU funded project, COGents (IST-2001-34431), developed a prototype agent based environment to allow for dynamic access to CAPE-OPEN tools distributed on the Internet. My own interests are in the definition of process design interfaces for distributed activities in engineering design.

Figure 7: A Jacaranda tree in el parque del Retiro, Madrid

Full details including licensing and installation instructions are in a separate document.

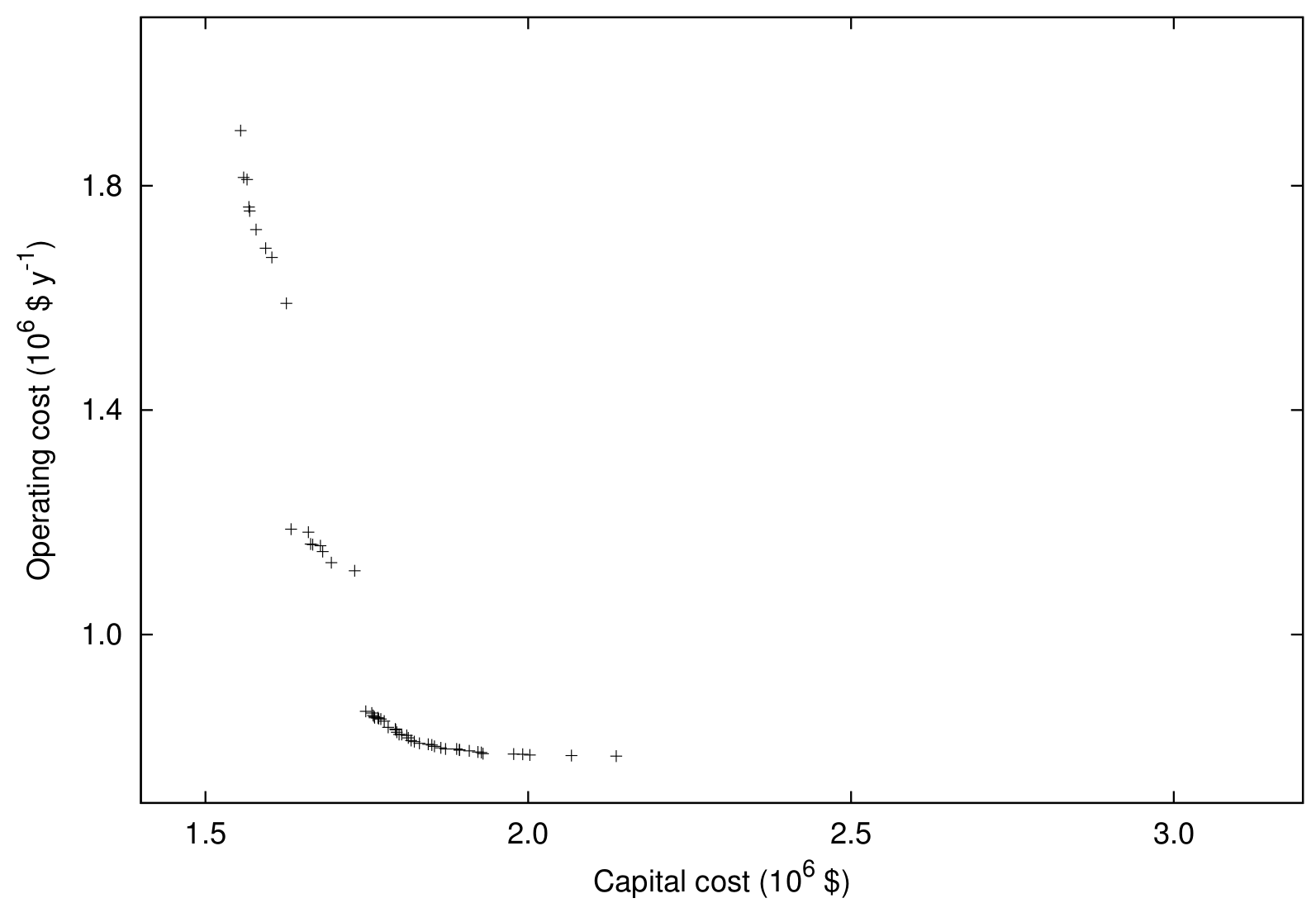

The Strawberry & Fresa plant propagation algorithms

For challenging nonlinear optimisation problems, we have developed a nature-inspired plant propagation algorithm known as Strawberry with a recent version, Fresa, written in the Julia language. The algorithm was developed in collaboration with Professor Abdellah Salhi, University of Essex. The method was originally described in Salhi & Fraga, 2011 where it was applied to the design of a process for the purification of chlorobenzene (see Figure 8 below). This new optimisation method has been further used for a number of applications, including the modelling of energy systems for domestic dwellings (Fraga et al., 2015), the design of large scale renewable energy generation systems with storage for off-grid mining operations (Fraga & Amusat, 2016), and the multi-objective optimal control of a beer fermentation process (Rodman et al., 2018). The method uses a novel fitness ranking algorithm for multi-objective optimisation, described in the second of these papers. The codes for Strawberry and Fresa are available for download for evaluation and use.

Figure 8: Approximation to Pareto front for a chlorobenzene purification process, showing trade-off between operating and capital costs.

Application areas

The research described above consists of methodologies and algorithms. These are, in principle, generic products which can be applied to a number of different application areas. However, the research in my group does focus on some areas. Specifically, the following application areas are of particular interest although the list is not exclusive:

- Energy

- Energy provision and use is a key concern currently due to a number of factors, including global warming and rising oil prices. My interests in this area include energy generation, storage and use:

- Delivery

Figure 9: Pareto front for fuel cell design, investigating the trade-off between fuel cell efficiency and its size.

We are investigating the use of detailed modelling and mathematical programming for the design of efficient fuel cells for the generation of heat and power. The graph above shows a typical trade-off, or Pareto, curve for system efficiency versus fuel cell size. Such results can enable an engineer to identify the design that best suits the needs of the application (e.g. a domestic heat and power source versus automotive use).

- Demand reduction

For energy reduction, we have developed a number of optimisation procedures for identifying suitable integration between sources and sinks of heat7. Although the procedures have been evaluated (through literature examples and with companies on real plants) for process design problems, the technologies developed can be adapted for more general integration problems such as at the urban level.

Figure 10: Graphical display for heat exchanger network design with stream splitting.

The screen displayed in the figure above is for the generation of structures for heat exchanger network generated using a Lindenmayer based hybrid optimisation procedure. The greyed out elements are part of the superstructure not used, as determined by a hybrid NLP solver. The superstructure is generated by the Lindenmayer approach.

- Generation and supply

- In the area of supply, we have concentrated on the design and analysis of processes for the generation of biofuels, with particular emphasis on ethanol and the production of hydrogen, using water splitting, for domestic use. For large scale bioethanol production, we are currently investigating process integration for improved energy efficiency and the impacts of pre-treatment on the whole process design through the use of large scale mixed integer nonlinear programming.

- Storage

- The increasing use of intermittent energy supplies (e.g. wind, solar, tidal) is posing a challenge to the traditional supply of energy via national grids. The grids often have regulatory obligations to meet peak demands and base loads are often based on these expected peaks. This often leads to over-capacity for base or average use when the extra provision from intermittent supplies is factored in. For large individual energy users, e.g. processing plants, the same issues apply. The use of storage to alleviate the mis-match that may exist between generation and demand in time is recognised as a key area of research. We have a project on the design of integrated energy generation and energy use systems for off-grid continuous mining operations.

- Waste

- In this area, we have concentrated on the development of tools for the design of mass exchange networks. The work in this area feeds into the energy area through the consideration of waste (e.g. municipal waste, lumber industry) as a valuable source of raw materials for biofuel production.

- Water

- We have developed optimisation models for the design of water distribution networks with redundancy and are interested in general water resource management. An on-going project is the development of HydroPlatform, an open platform for network models in this area.

Highlighted projects

Below is a list of some of the research projects currently under way or recently finished. When possible, I have included the name(s) of the main researchers and any collaborators. A short presentation is also available.

- The design and implementation of a computational framework for design under uncertainty. Student: Pedro de Oliveira Filho.

- Modelling of novel separations technologies for the nuclear reprocessing cycle including the automated design of new reprocessing flowsheets. This is part of the PACIFIC project, Providing a Nuclear Fuel Cycle in the UK for Implementing Carbon Reductions. Davide Bascone is the student working on this project, co-supervised by Professor P Angeli. This research fits in with the broader research in nuclear energy at UCL.

- Scale-up of delivery and coating processes for the Sustainable Manufacturing of Transparent Conducting Oxide (TCO) Inks and Thin Films, in collaboration with Professor Claire Carmalt (UCL Chemistry) and with Professor P Angeli.

- Modelling and optimisation for integrated energy systems, combining renewable energy (solar, wind) with large scale energy storage technologies (molten salts, pumped hydraulic, compressed air) for off-grid continuous mining operations in remote regions of the Earth. Student: Oluwamayowa Amusat, co-supervised with Dr Paul Shearing.

- Modelling and optimisation of distributed energy through micro-generation and storage technologies for residential use in neighbourhoods. Student: Carmen Wouters, co-supervised with Dr A James (UCL Australia). See C Wouters, E S Fraga, A M James (2015), Energy 85:30-44.

- Design of novel separation processes and consideration of energy integration for the production of ethanol from lignocellulosic biomass. Student: Cristian Triana, co-supervised with Professor E Sorensen.

Recent presentations

Following are links to some of the recent presentations (conferences and seminars) given for the work in my research group:

- University of Essex

- Literate programming and reproducible research, presentation at the EGL 2018 meeting, discussing the use of org mode in Emacs for reproducible research.

- Salamanca

- Stochastic methods and models for multi-objective dynamic optimisation problems, Seminar given at the University of Salamanca, October 2017.

Footnotes:

E S Fraga (2006). Hybrid methods for optimisation, in Computer Aided Methods for Optimal Design and Operations (World Scientific Publishing Co.), J. Žilinskas and I. D. L. Bogle, editors, 1-14.

A Žilinskas, E S Fraga & A Mackutė (2006). Data analysis and visualisation for robust multi-criteria process optimisation, Computers & Chemical Engineering 30(6-7):1061-1071.

K Wang, A Salhi & E S Fraga (2004), Process design optimization using embedded hybrid visualization and data analysis techniques within a stochastic optimization framework. Chemical Engineering and Processing 43 (5):657-669, DOI: 10.1016/j.cep.2003.01.001.

E S Fraga & L G Papageorgiou (2007), A Two Step Hybrid Optimization Procedure for the Design of Optimal Water Distribution Networks, in Aimo Törn & Julius Žilinskas (Editors), "Models and Algorithms for Global Optimization: Essays Dedicated to Antanas Žilinskas on the Occasion of his 60th Birthday.'' Optimization and Its Applications, Volume 4, Springer, 311-332.

E S Fraga, R Patel & G W A Rowe (2001). A visual representation of process heat exchange as a basis for user interaction and stochastic optimization, Chemical Engineering Research & Design 79(A7):765-776.

E S Fraga, M A Steffens, I D L Bogle & A K Hind (2000). An object oriented framework for process synthesis and simulation, in "Foundations of Computer-Aided Process Design," M F Malone, J A Trainham & B Carnahan, editors (AIChE Symposium Series) 96(323):446-449.

E S Fraga (2009). A rewriting grammar for heat exchanger network structure evolution with stream splitting, Engineering Optimization 41 (9):813-831, UCL eprints, DOI: 10.1080/03052150903070153.